A method of assembly-type construction of open-cut underground building structures

An underground building and construction method technology, applied in underwater structures, infrastructure engineering, construction, etc., can solve the troublesome construction of the main structure, high requirements for the workability and fluidity of concrete, and the widening of the station structure, etc. problems, to achieve the effect of reducing the production and binding of steel bars and concrete pouring and maintenance, reducing the temporary construction area, land occupation width and area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

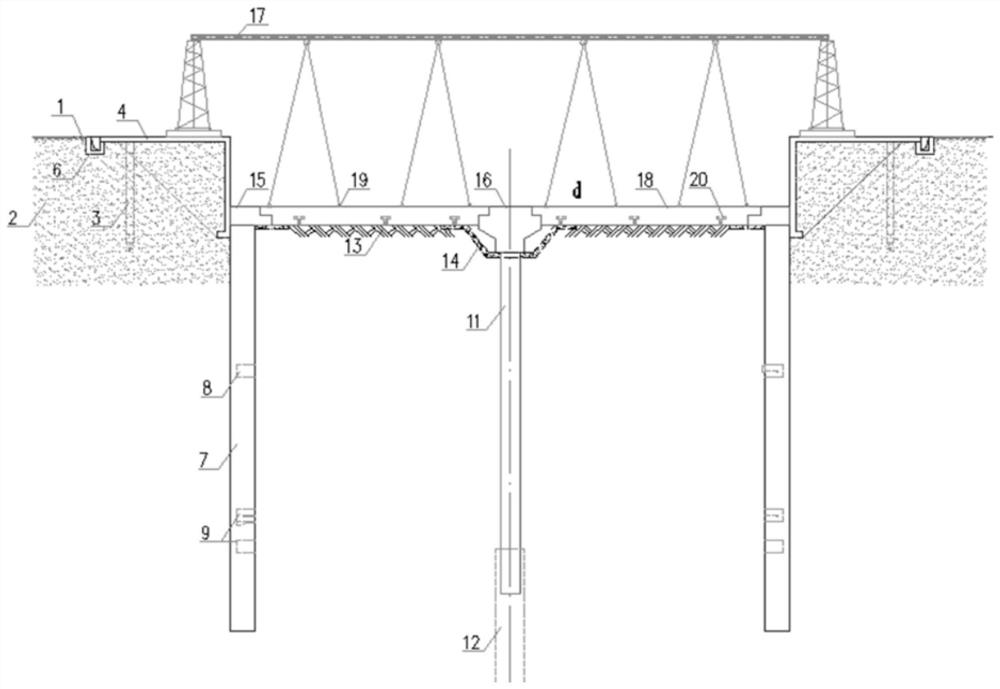

[0053] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

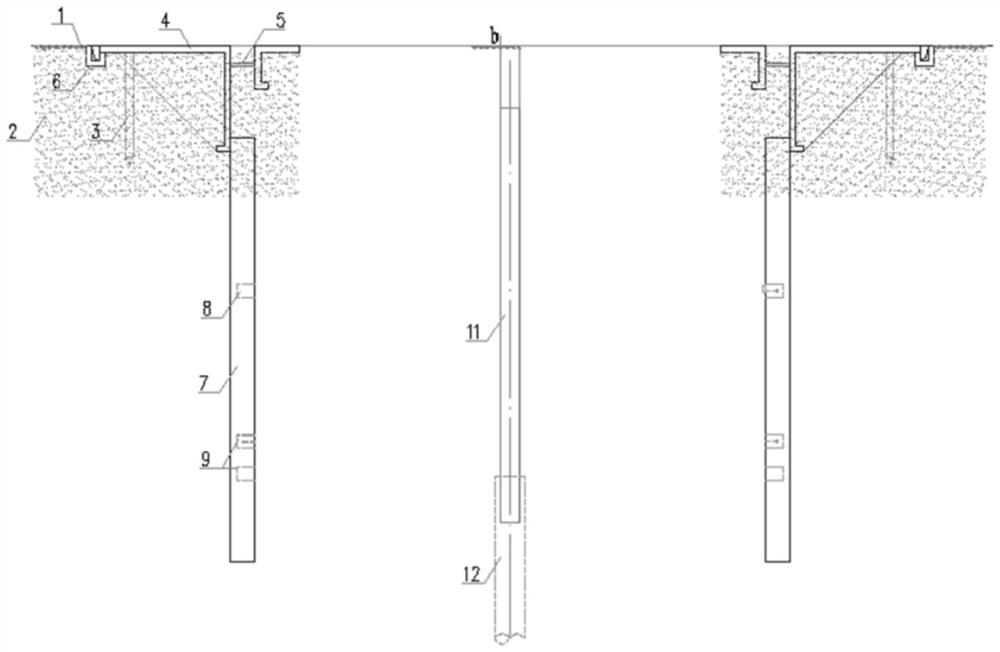

[0054] Such as Figure 1-6 As shown, a kind of open-cut underground building structure assembly type construction method described in the present invention comprises the following steps:

[0055] S1. Carry out the construction of the guide wall for guiding the construction of the underground connecting wall on the site within the construction scope of the main body of the station;

[0056] Such as figure 1 Shown: the underground pipelines and structures are relocated within the construction scope of the main structure of the underground station, and obstacles are cleared for the construction of the guide wall (4) and the underground diaphragm wall (7).

[0057] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com