Non-welding fabricated steel pipe concrete beam-column joint and its construction method

A technology of concrete-filled steel tube columns and concrete-filled steel tubes, which is applied in the direction of construction and building construction, and can solve problems such as long welding time, complicated construction procedures, and large residual stress in welding, so as to reduce the configuration and binding of steel bars and simplify the structural design , The effect of improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the drawings, and detailed descriptions are made as follows.

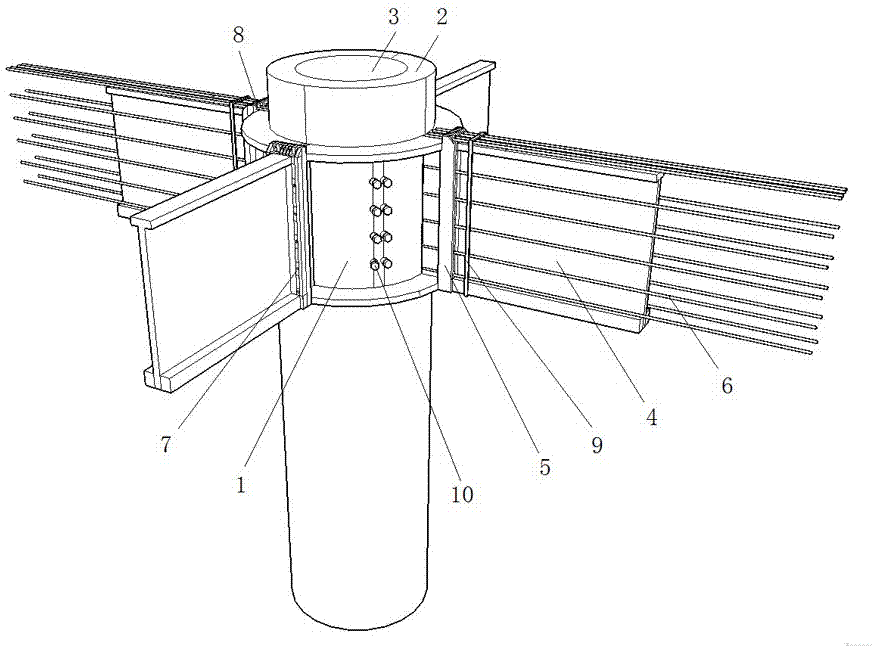

[0020] Such as figure 1 As shown, a non-welded fabricated concrete-filled steel tube beam-column node includes a concrete-filled steel tube column, the concrete-filled steel tube column is sheathed with an annular sleeve 1, and a plurality of reinforced concrete beams are circumferentially arranged on the circumferential side of the annular sleeve .

[0021] In the embodiment of the present invention, the concrete-filled steel tube column includes a steel tube column 2 in which concrete 3 is poured.

[0022] In the embodiment of the present invention, the reinforced concrete beam includes an outwardly extending I-shaped steel plate 4, and the I-shaped steel plate 4 is provided with an n-shaped protrusion 5 at the end close to the annular sleeve 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com