Centralized winding motor end part patch board

A centralized technology at the end of the motor, applied in the direction of windings, electrical components, electromechanical devices, etc., can solve the problems of unable to meet the quality of high-current welding, complicated welding of the end coils, and affecting the performance of the motor, so as to achieve less copper loss of the motor , Phase-to-phase breakdown failure reduction, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Structure description:

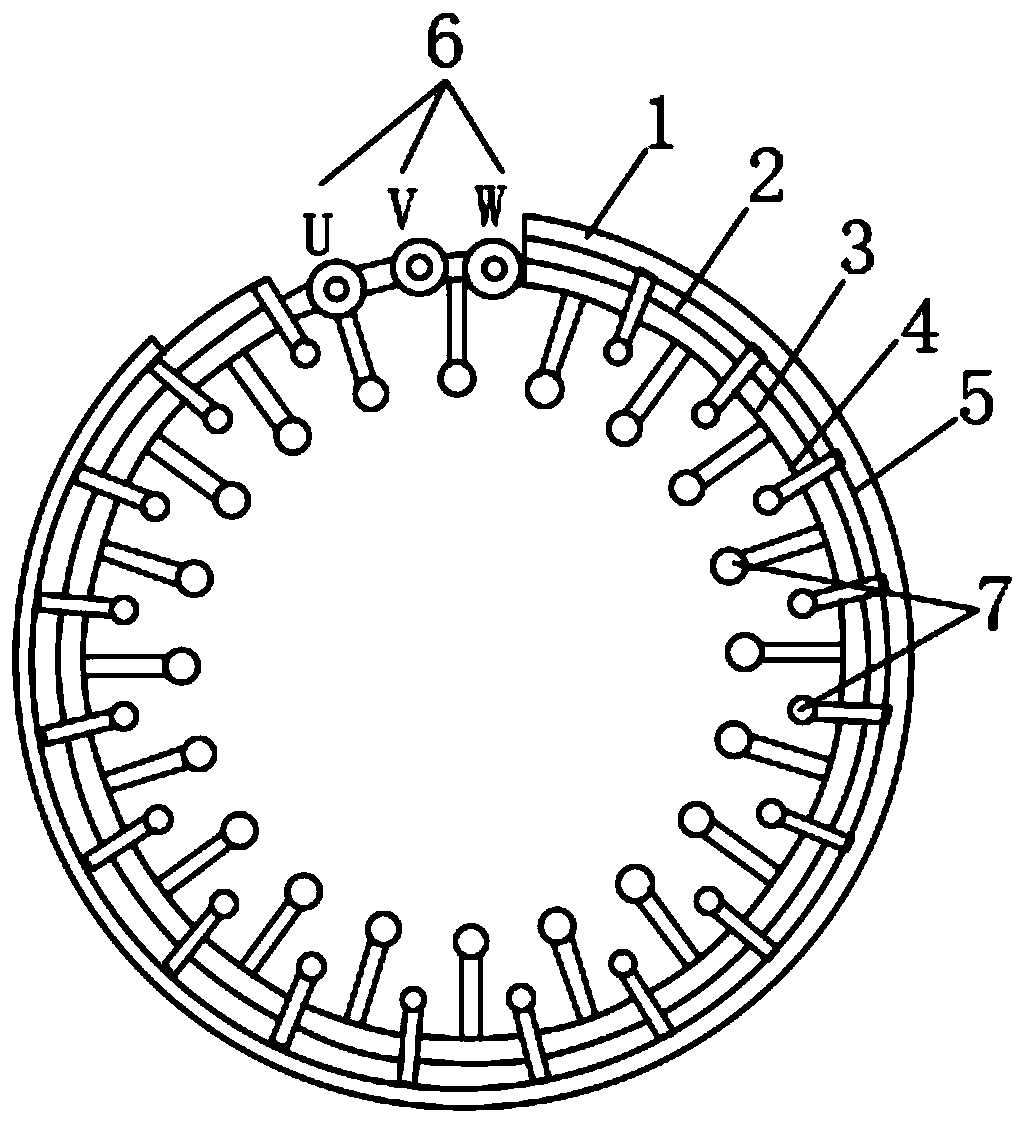

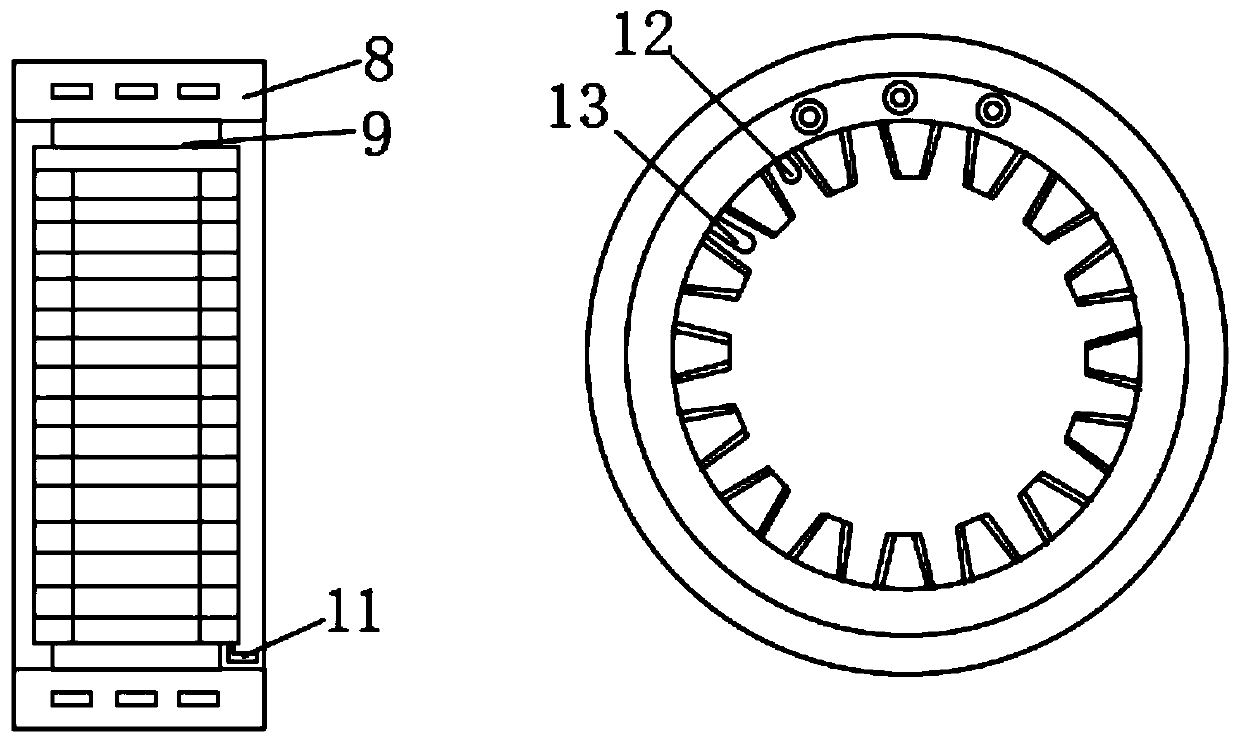

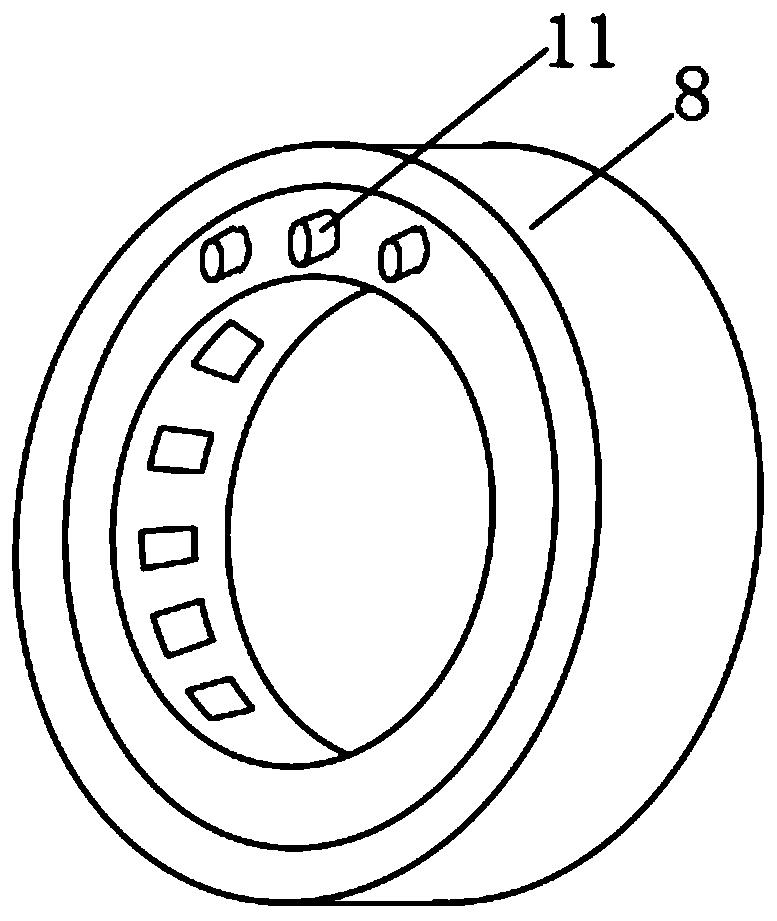

[0022] This patent centralized winding motor end winding wiring board is attached. figure 1 , consists of 1-1V phase connection copper bar 1, 1-2W phase connection copper bar 2, 1-3U phase connection copper bar 3, 1-4 center line 4 and 1-6U, V, W three-phase terminal 6.

[0023] 1-6U, V, W three-phase terminal 6 and 1-4 center line 4 are connected to the copper bar with pin 7 welded to the motor winding. The number of pin 7 is related to the number of motor windings, and the 1-1V phase is connected to the copper The width and thickness of row 1, 1-2W phase connection copper row 2, 1-3U phase connection copper row 3 are related to the current of the motor winding, 1-1V phase connection copper row 1, 1-2W phase connection copper row 2, 1 - 3U phase connection copper bar 3 is punched and formed into a ring shape, U, V, W three-phase connection copper bar is riveted and pressed with three-phase terminal as the lead-out of the motor winding.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com