A high temperature gas-cooled reactor nuclear power plant steam generator cabin module

A technology of steam generator and high-temperature gas-cooled reactor, which is applied to small buildings, building components, walls, etc., can solve the problems of inability to complete the installation of equipment and pipelines, increasing the difficulty of construction quality control, and difficulty in adjusting the accuracy of supporting embedded parts, etc. Achieve the effect of overcoming the problem of hoisting deformation, reducing the temperature, and reducing the difficulty of seating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

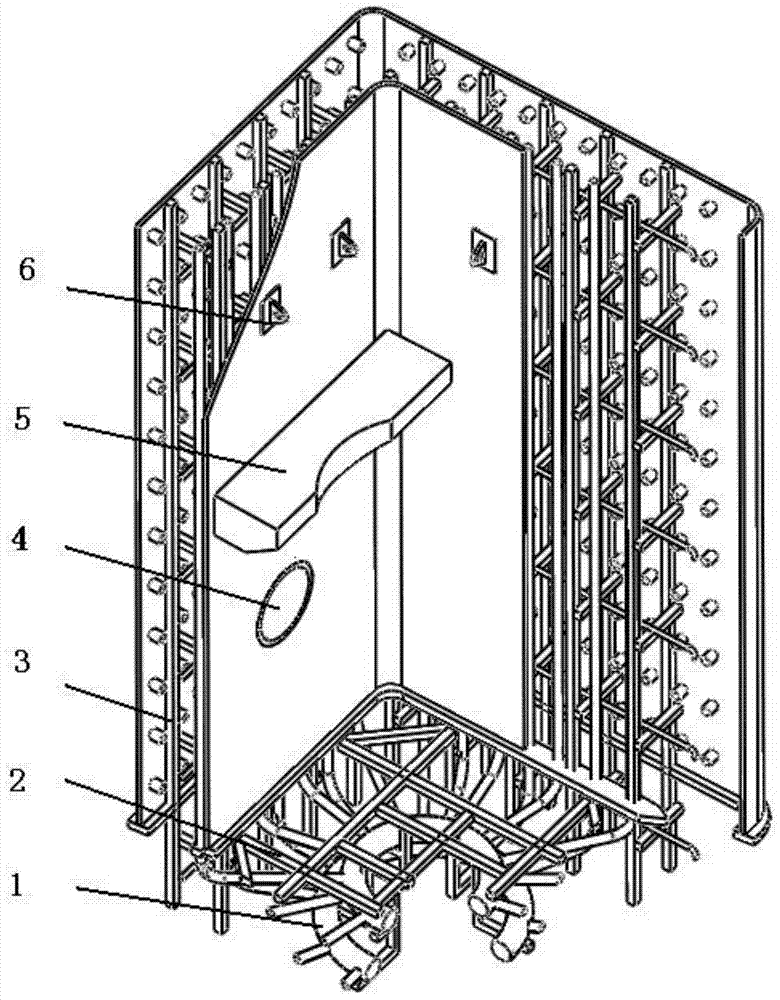

[0035] Such as figure 1 As shown, the main body of the steam generator cabin module is a wall structure 3 surrounded by four walls. The bottom structure 2 is installed under the wall structure 3 , and the shielded cooling water system 1 is installed under the bottom structure 2 . An evaporator supporting embedded part 5 is installed inside the wall structure 3 . A penetrating member 4 is installed on the wall surface of the wall structure 3 . Hanging lugs 6 are installed on the inner side of the wall structure 3 .

[0036] The structure of each part is specifically described below.

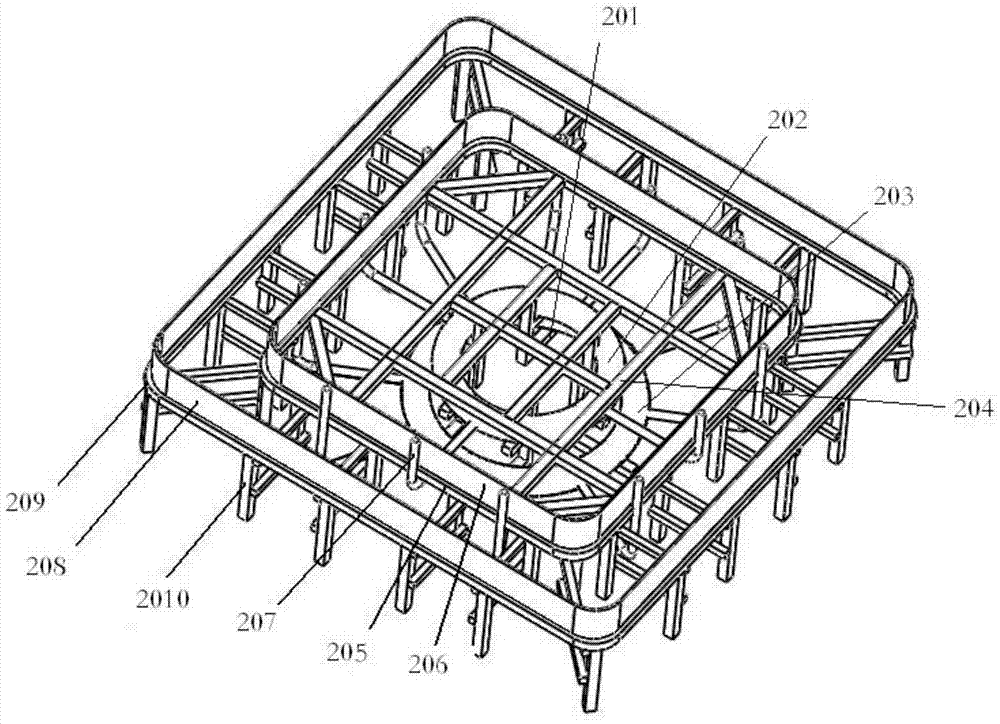

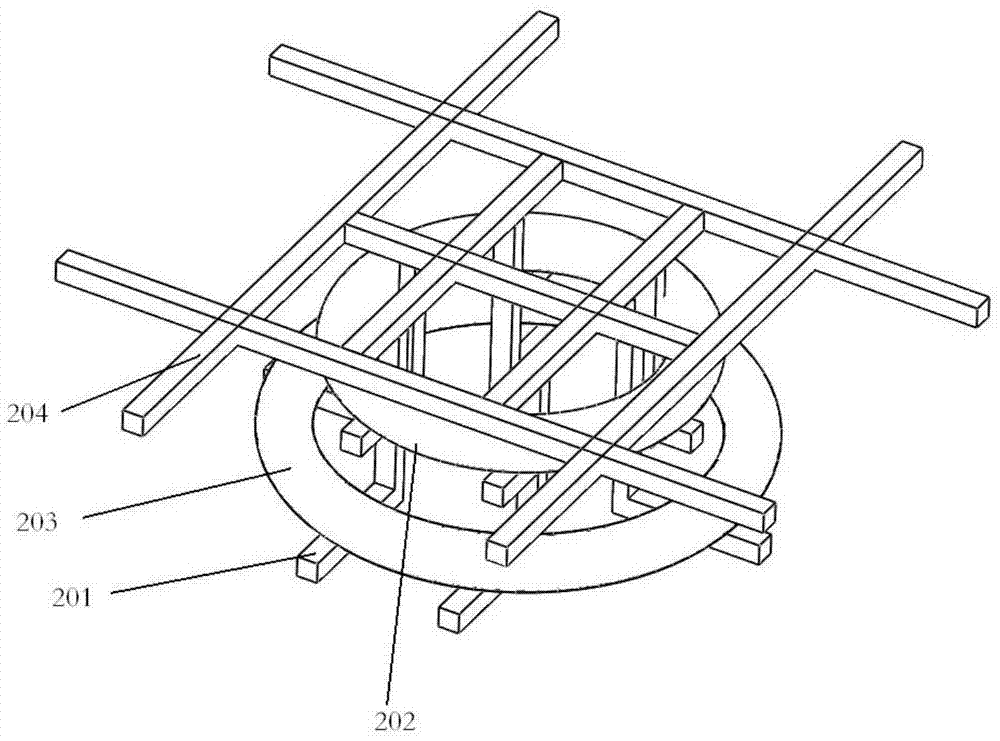

[0037] Such as figure 2 As shown, the bottom structure 2 includes a bottom outer wall 208 and a bottom inner wall 206, an outer wall support steel frame 2010 is installed under the bottom outer wall 208, an inner wall support steel frame 207 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com