Prefabricated mixed limb wall system and its construction method

A connected limb wall and prefabricated technology, which is applied in the direction of walls, building components, and earthquake resistance, can solve the problems of low efficiency, large construction waste, and large field operations of connected limb walls, and achieves excellent shear yield energy consumption performance, Guaranteed construction quality and strong ability to resist progressive collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

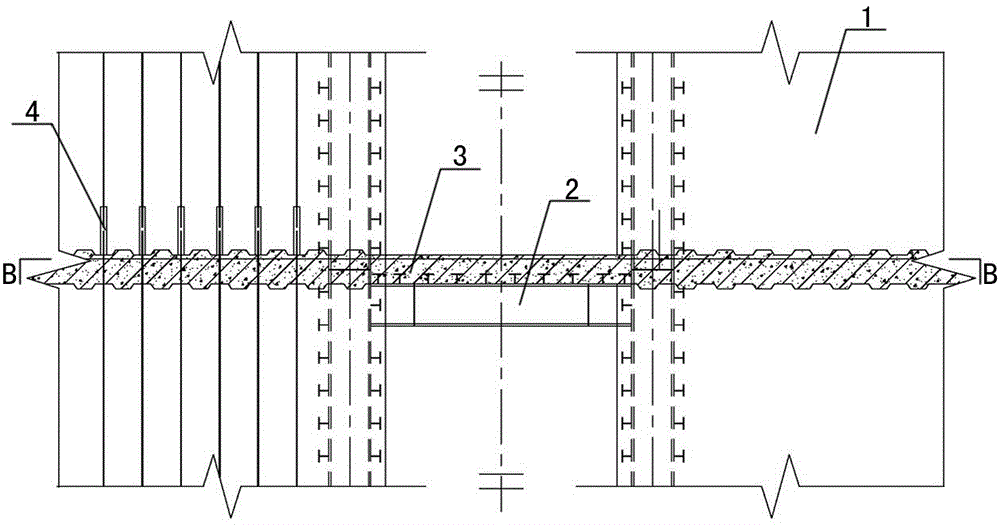

[0045] Examples see image 3 , Figure 4 As shown, a prefabricated mixed limb wall system includes wall units 1 connected in the horizontal direction and vertical direction respectively, wherein a floor 3 is arranged between the wall units connected in the vertical direction, and the floor 3 is the on-site The poured concrete structure or the fabricated prefabricated concrete structure, the sum of the height of the concrete wall of the wall unit and the height of the floor slab 3 is consistent with the floor height.

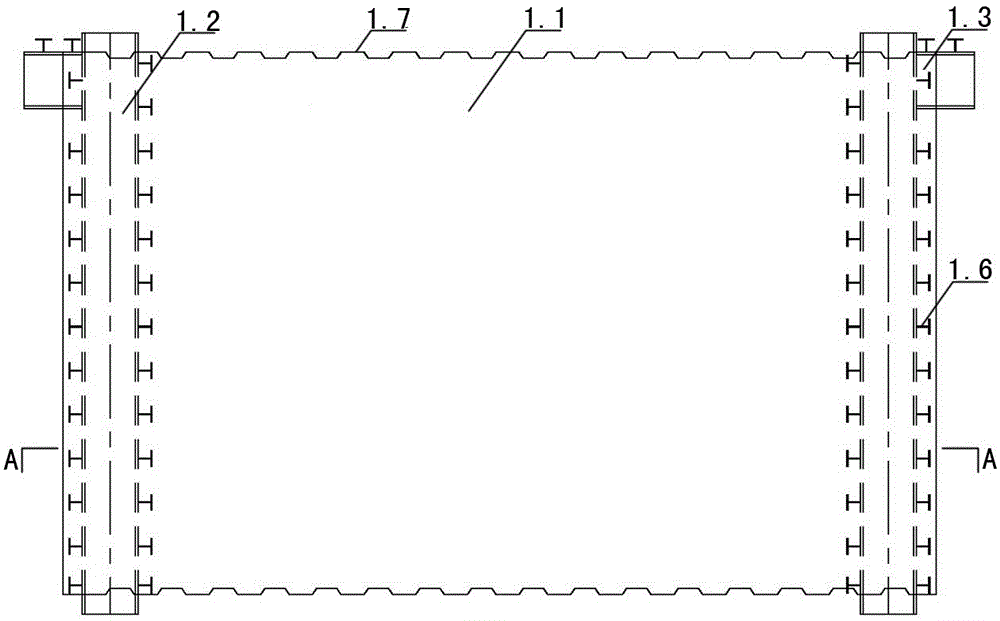

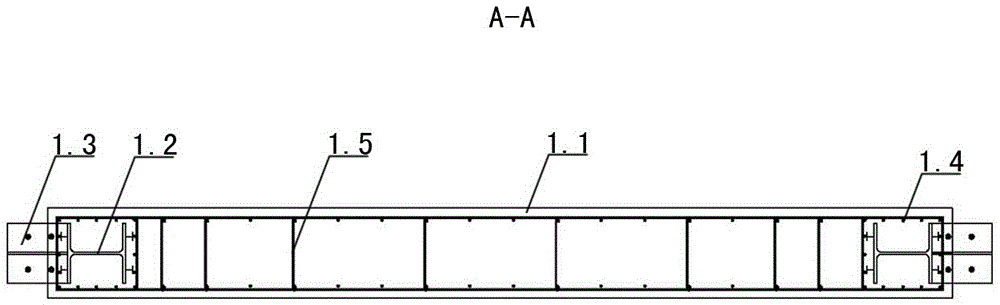

[0046] see figure 1 , figure 2As shown, the wall unit 1 includes a concrete wall 1.1, steel columns 1.2 erected at both ends of the concrete wall 1.1, and a steel skeleton 1.5 located inside the concrete wall 1.1; the upper and lower ends of the steel column 1.2 exceed The concrete wall 1.1, the upper ends of the two steel columns 1.2 located in the concrete wall 1.1 are respectively connected with non-energy dissipating short beams 1.3 opposite to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com