Regenerative block concrete connecting joint provided with H-shaped steel and U-shaped steel

A technology for connecting nodes and H-shaped steel, which is applied in the direction of construction and building construction, to achieve the effects of simplified crushing, efficient recycling, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

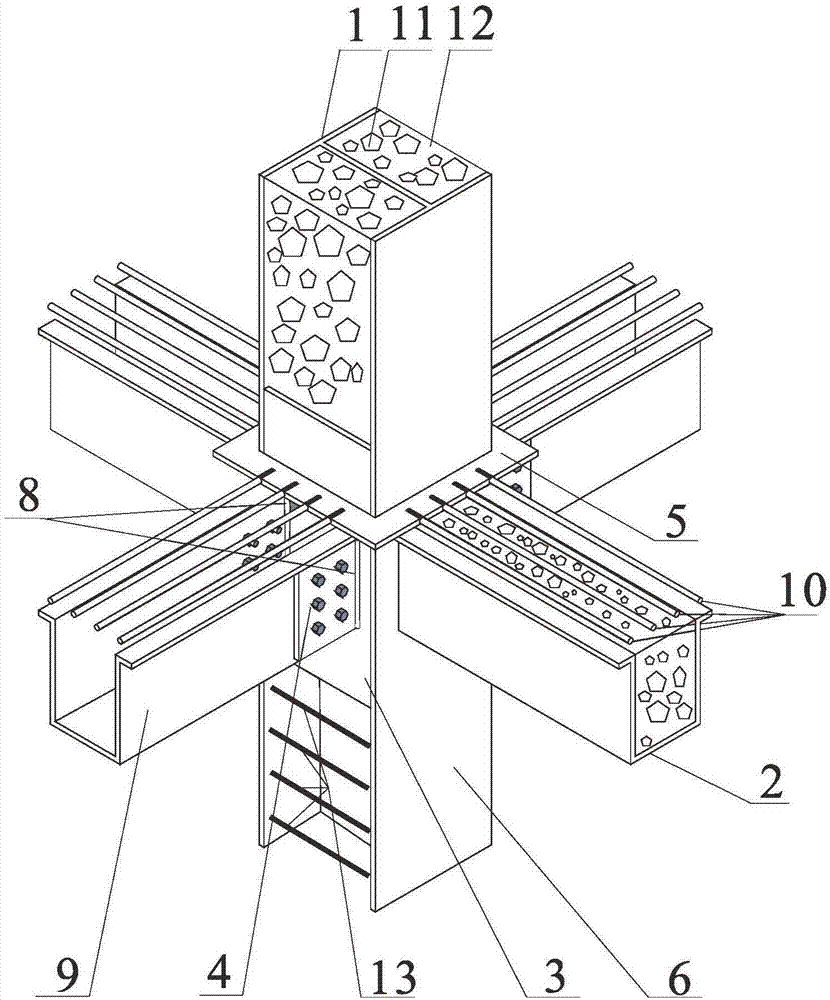

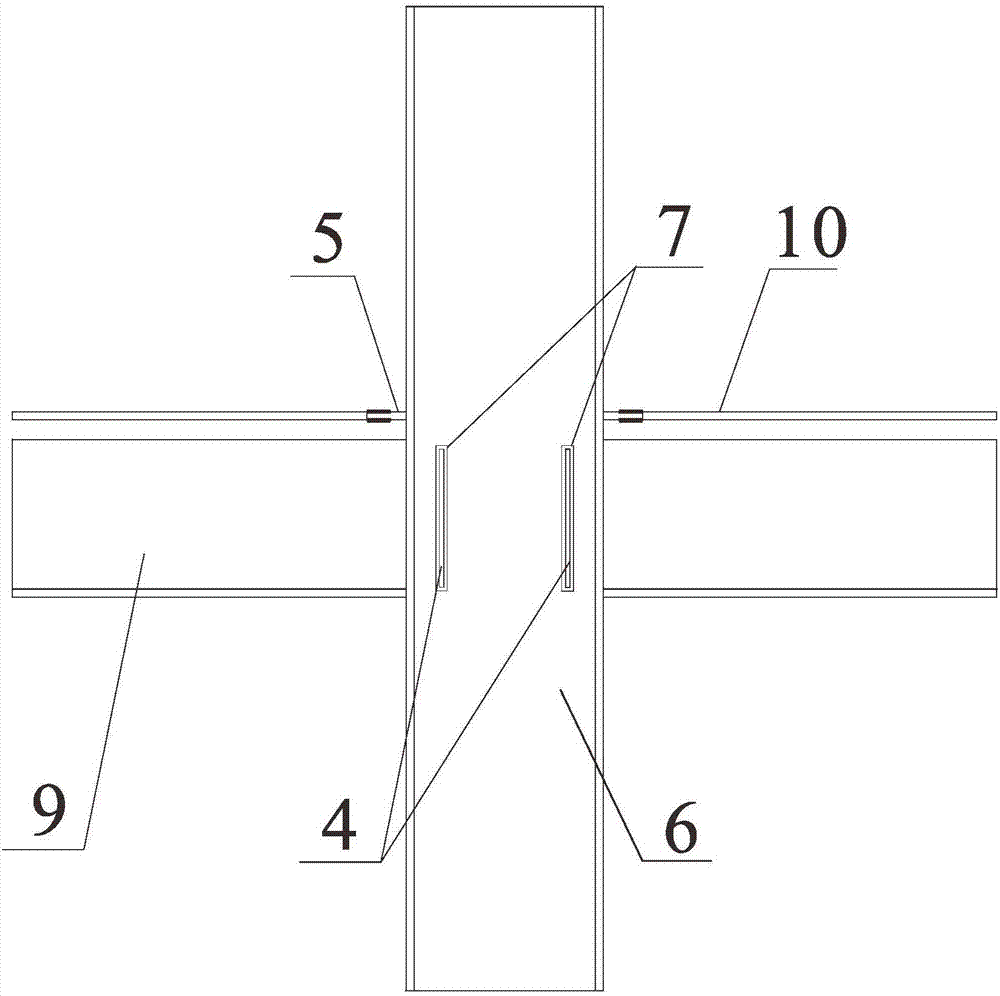

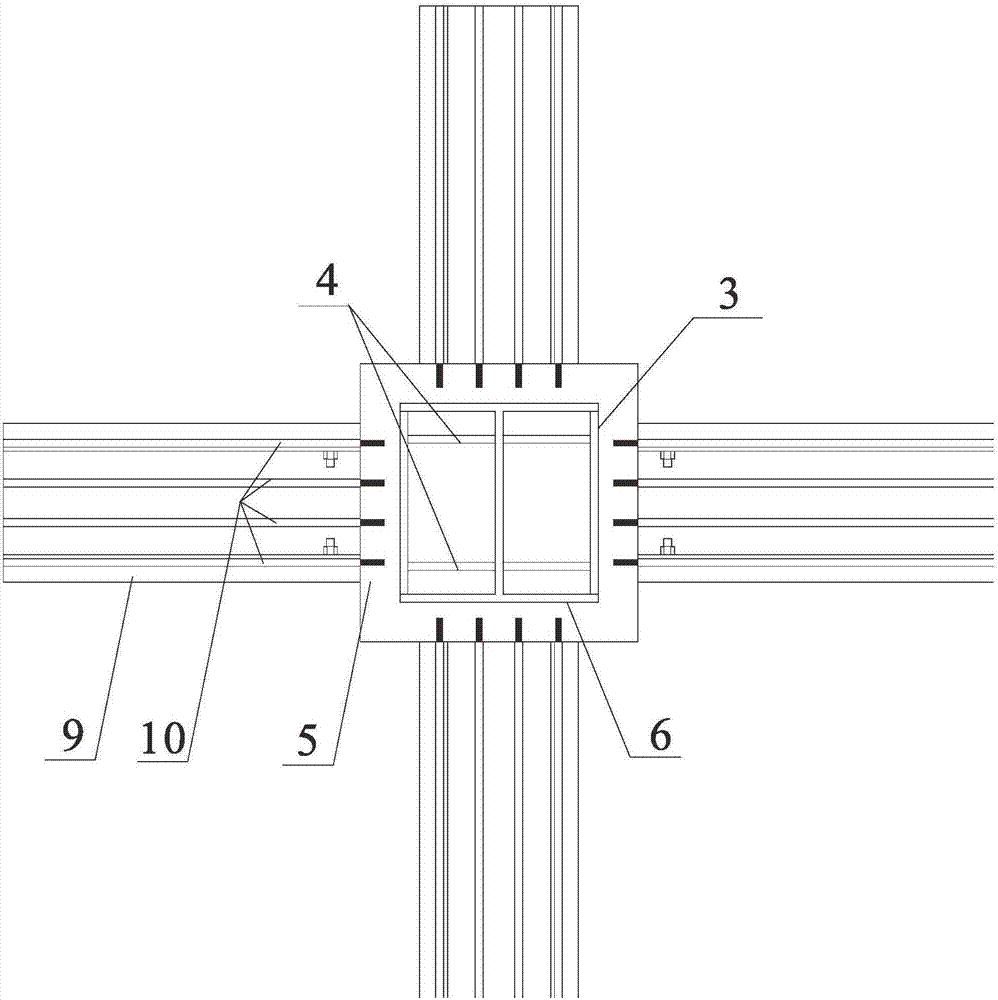

[0030] Such as figure 1 , 2. As shown in 3, a recycled block concrete connection node with H-shaped steel and U-shaped steel, including a part of the H-shaped steel composite column 1 provided with H-shaped steel 6, which is horizontally fixed on the part of the H-shaped steel composite in a cross shape The full-outsourcing U-shaped steel composite beam 2 on the column 1, the fully-outsourcing U-shaped steel composite beam 2 includes a U-shaped steel 9, and also includes two first rectangular steel plate connectors 3 parallel to the web of the H-shaped steel 6, Two second rectangular steel plate connectors 4 perpendicular to the web of the H-shaped steel 6, a square outer ring plate 5 with a threaded sleeve, and the two first rectangular steel plate connectors 3 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com