Double narrow ring plate-frp joint of thin-walled steel pipe recycled mixed columns and steel beams

A thin-walled steel pipe and mixed column technology, applied in construction, building structure and other directions, can solve the problems of unfavorable waste concrete placement, small steel pipe wall thickness, etc., and achieve the effects of saving manpower, saving steel consumption, and efficient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with embodiment and accompanying drawing, but implementation of the present invention

[0028] The method is not limited thereto, and it should be pointed out that, if there are any processes not specifically described in detail below, those skilled in the art can refer to the prior art to implement.

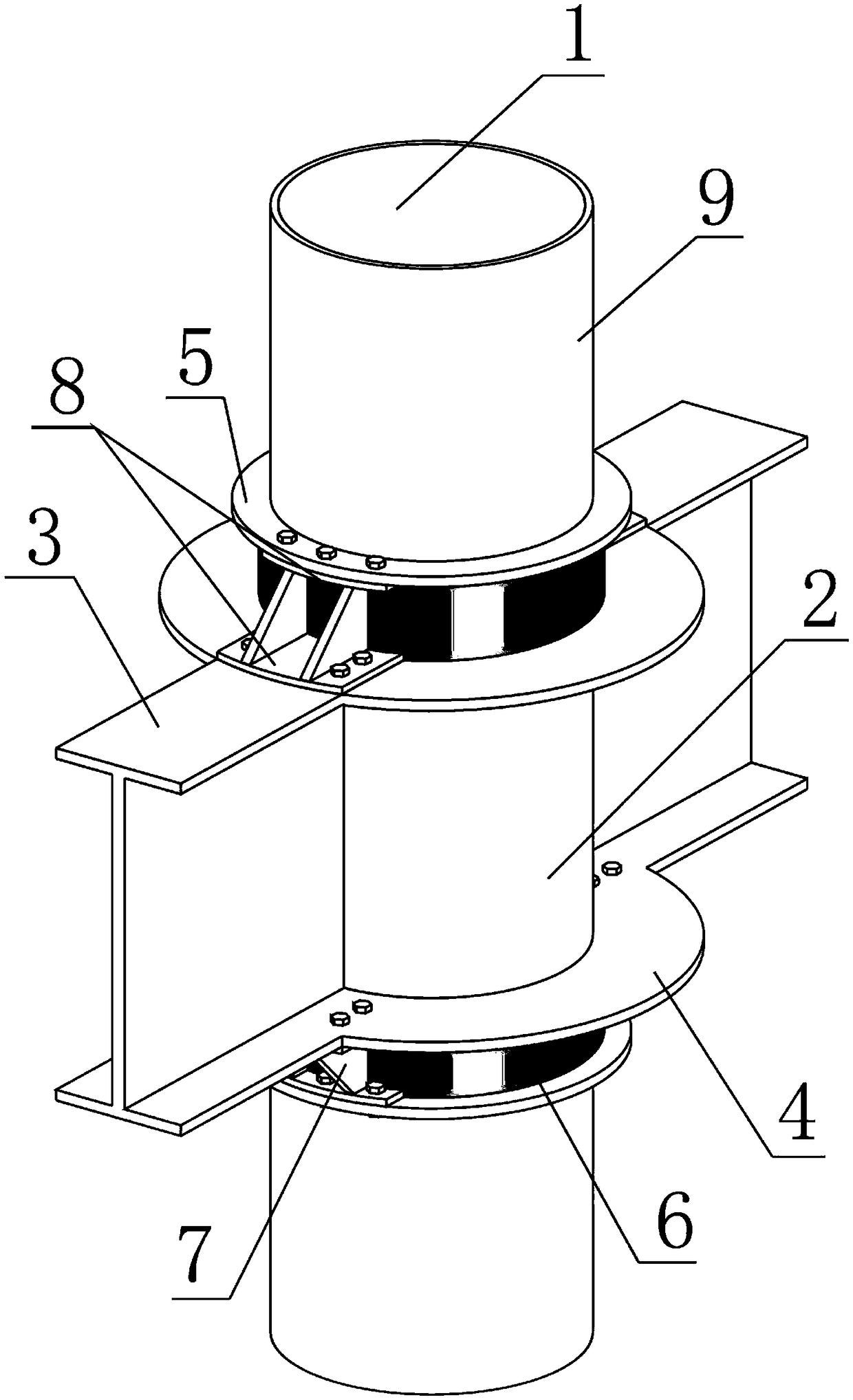

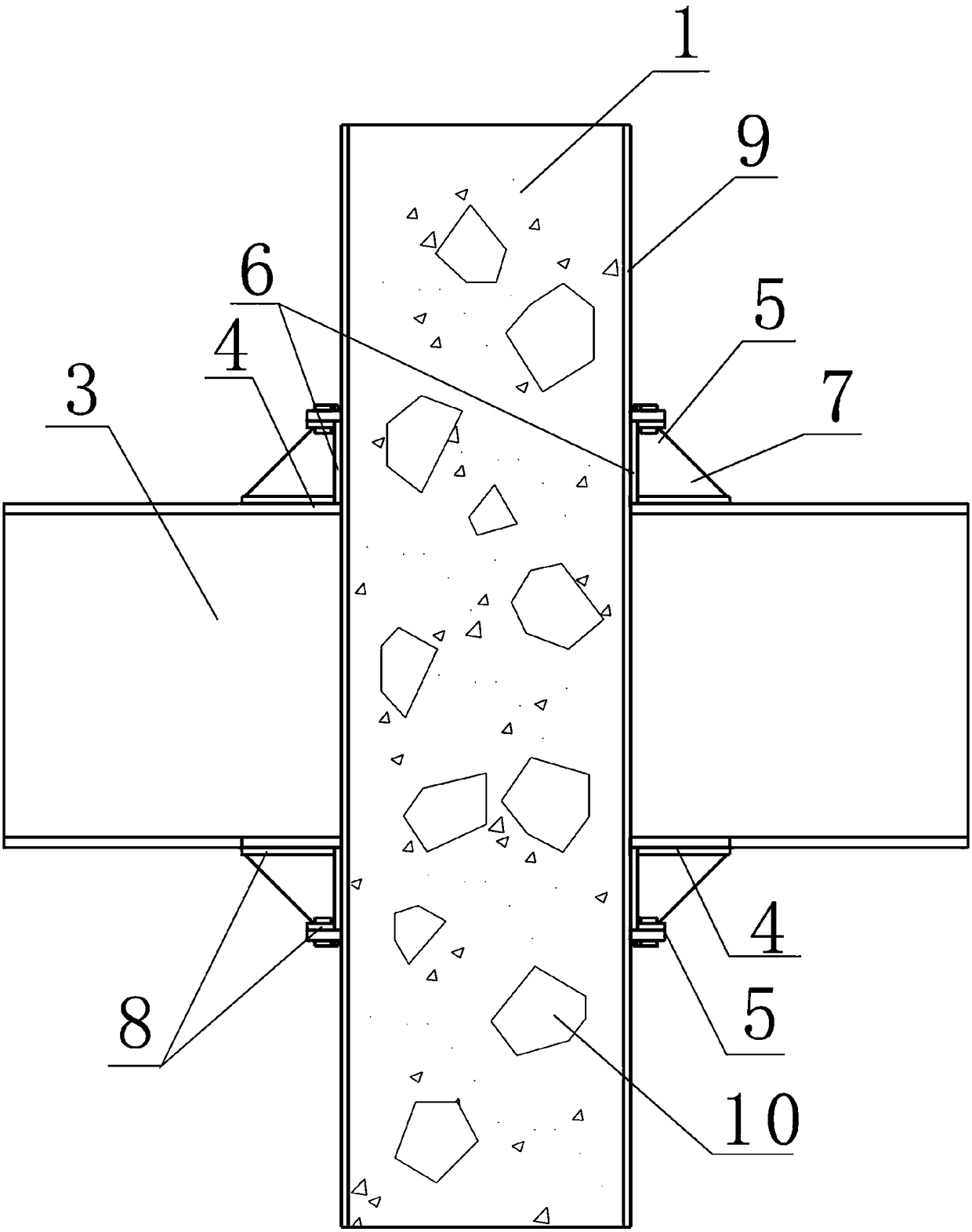

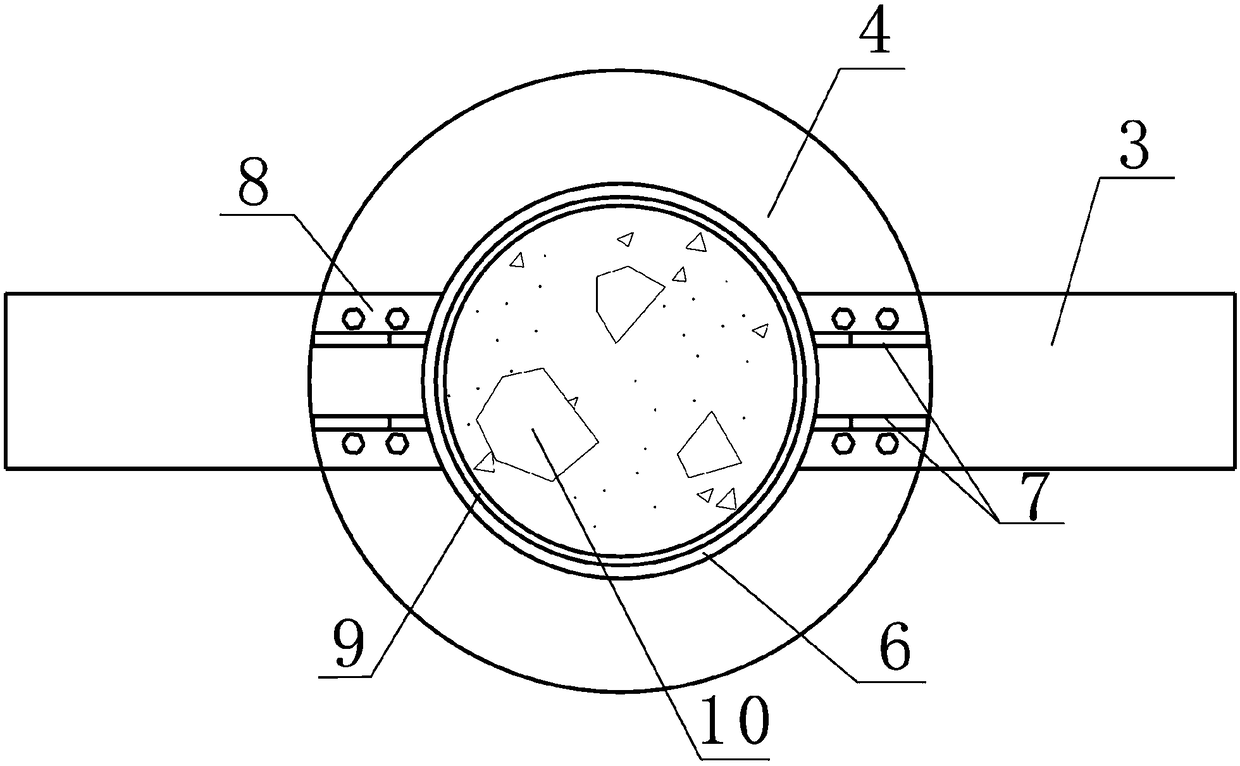

[0029] like Figure 1 to Figure 3 As shown, a double-layer narrow ring plate-FRP joint of thin-walled steel pipe recycled mixed column and steel beam includes a node domain 2 formed by the intersection of thin-walled steel pipe recycled mixed column 1 and steel beam, which is symmetrically arranged on the Two sets of double-layer narrow ring plates on the upper and lower sides of the node domain 2, FRP hoops 6 and composite ribs, steel corbels 3 symmetrically arranged on the left and right sides of the node domain 2, and the steel beams pass through the steel corbels 3 is connected to the node...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com