Composite foundation of large-diameter high-temperature fused salt storage tank and using method thereof

A high-temperature molten salt storage tank and composite technology, applied in infrastructure engineering, construction, etc., can solve the problems of insufficient design elements, thinness, and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

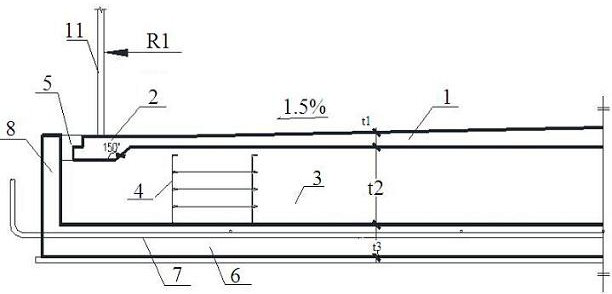

[0041] This embodiment provides a composite foundation for a large-diameter high-temperature molten salt storage tank, including a variable stiffness roof, a rigid bottom plate 6 and an outer ring wall 8, the variable stiffness roof is connected to the upper part of the outer ring wall 8, and the rigid bottom plate 6 and the outer ring wall 8 are integrally poured, the variable stiffness roof is close to the bottom of the storage tank 11, an outer insulation layer 5 is provided between the variable stiffness roof and the outer ring wall 8, and the variable stiffness roof and the rigid bottom plate 6 An intermediate thermal insulation filling layer 3 is provided in between, and the intermediate thermal insulation filling layer 3 is provided with compartment steel beams 4 at equal intervals along the vertical direction.

[0042]The composite foundation of this large-diameter high-temperature molten salt storage tank provided by the present invention directly bears the load of the...

Embodiment 2

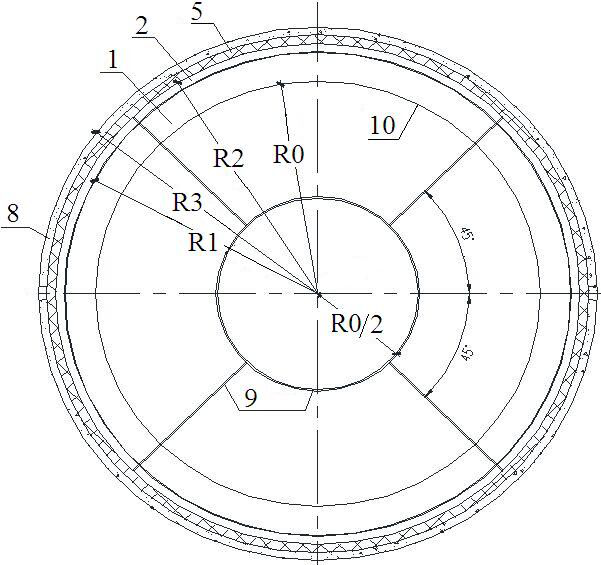

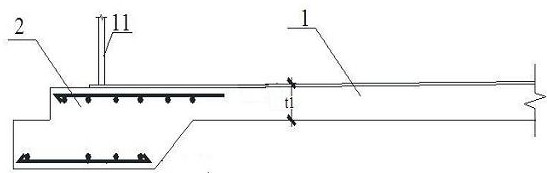

[0044] On the basis of Example 1, this example provides a composite foundation for a large-diameter high-temperature molten salt storage tank. The variable stiffness roof includes a special-shaped ring beam 2 and a conical roof 1. The conical roof 1 is a Thick plate, the tapered top plate 1 is fixed on the inner ring of the special-shaped ring beam 2, the special-shaped ring beam 2 is set under the tank wall of the storage tank 11, and the tapered top plate 1 is close to the bottom plate of the storage tank 11. Such as figure 1 , figure 2 shown.

[0045] Wherein, in the figure, R0 is the radius of the cone surface, R1 is the radius of the storage tank 11 , R2 is the radius of the ring beam, and R3 is the radius of the outer ring wall 8 . During the construction of the variable stiffness roof, it is poured in five parts, which are the central part of the cone and the four 90° sectors in the circumferential direction of the cone. There is a temperature expansion joint 9 betwe...

Embodiment 3

[0048] On the basis of Embodiment 1, this embodiment provides a composite foundation for a large-diameter high-temperature molten salt storage tank. There is a temperature-measuring layer inside the rigid bottom plate 6, and multiple thermoelectric devices are evenly embedded in the temperature-measuring layer. Even, a plurality of ventilation pipes 7 are arranged under the temperature measuring layer, and the thermocouple electric signal is connected with a control cabinet, and the control cabinet is electrically connected with a fan and an alarm, and one end of the ventilation pipe 7 communicates with the air outlet of the fan.

[0049] Such as figure 2 and Image 6 Shown, ventilation pipe 7 one ends are 90 °, communicate with the air outlet of blower fan. The temperature-measuring thermocouples are evenly embedded in the circular bottom plate, and the thermocouples gather at one place at the edge of the foundation. Ventilation pipes 7 are arranged below the thermocouple l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com