Detachable steel beam-concrete filled steel tube column penetrating connection joint

A technology for concrete-filled steel tubular columns and connecting nodes, which is applied in the direction of buildings and building structures, can solve the problems of no detachable function, difficult to ensure construction quality, and difficult to replace beams, etc., to prevent shear damage, improve strength and rigidity. , reduce the effect of welding work and template work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

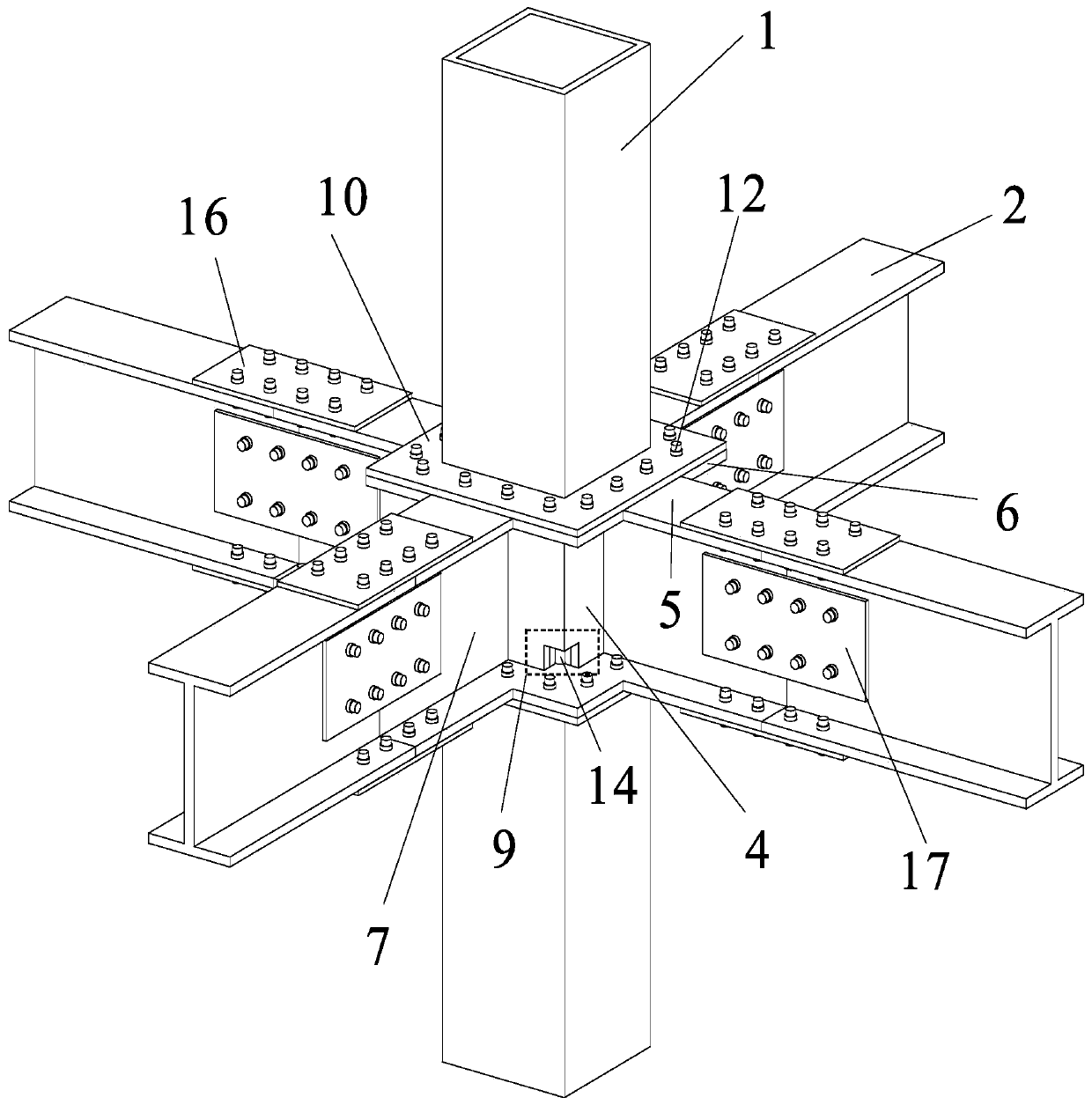

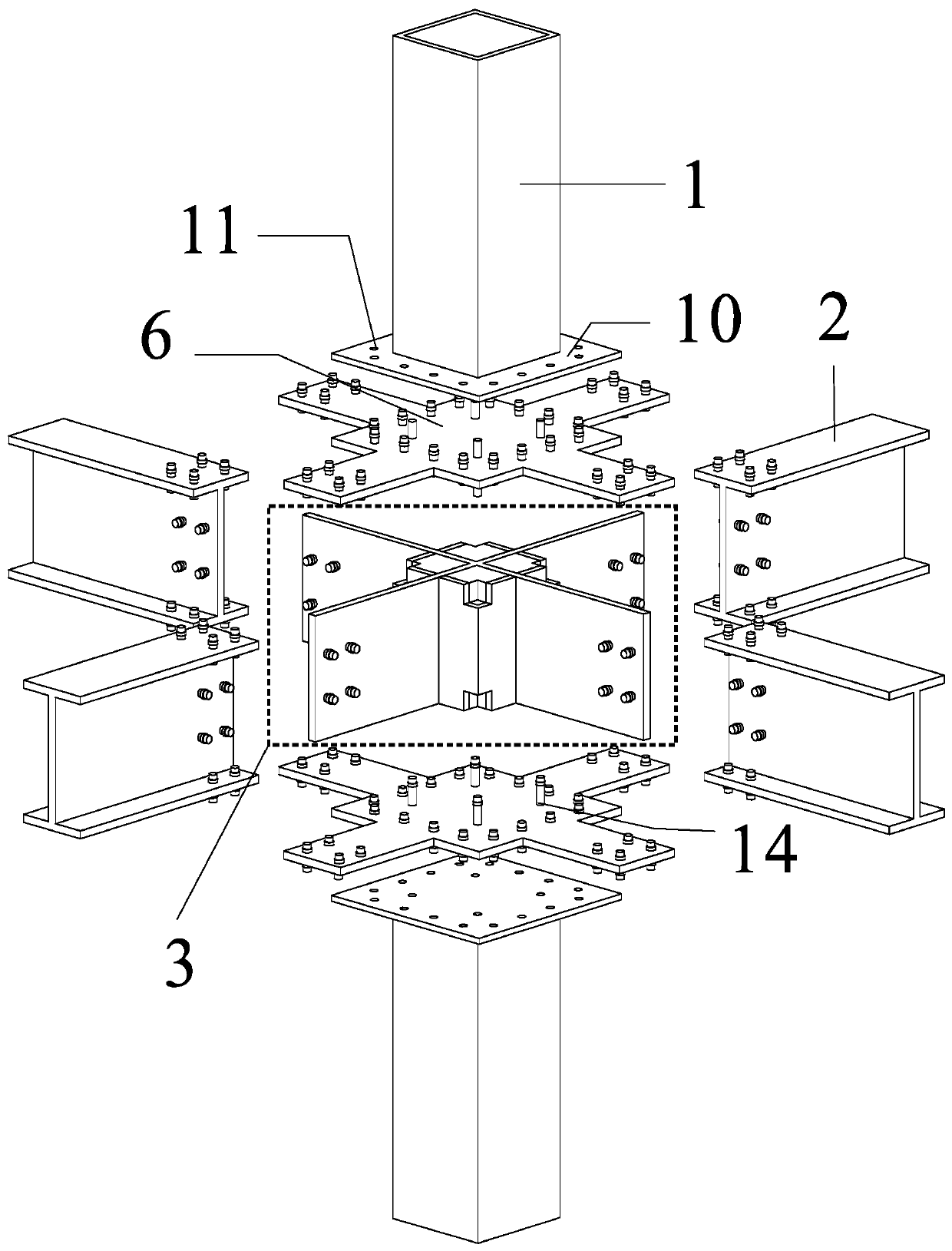

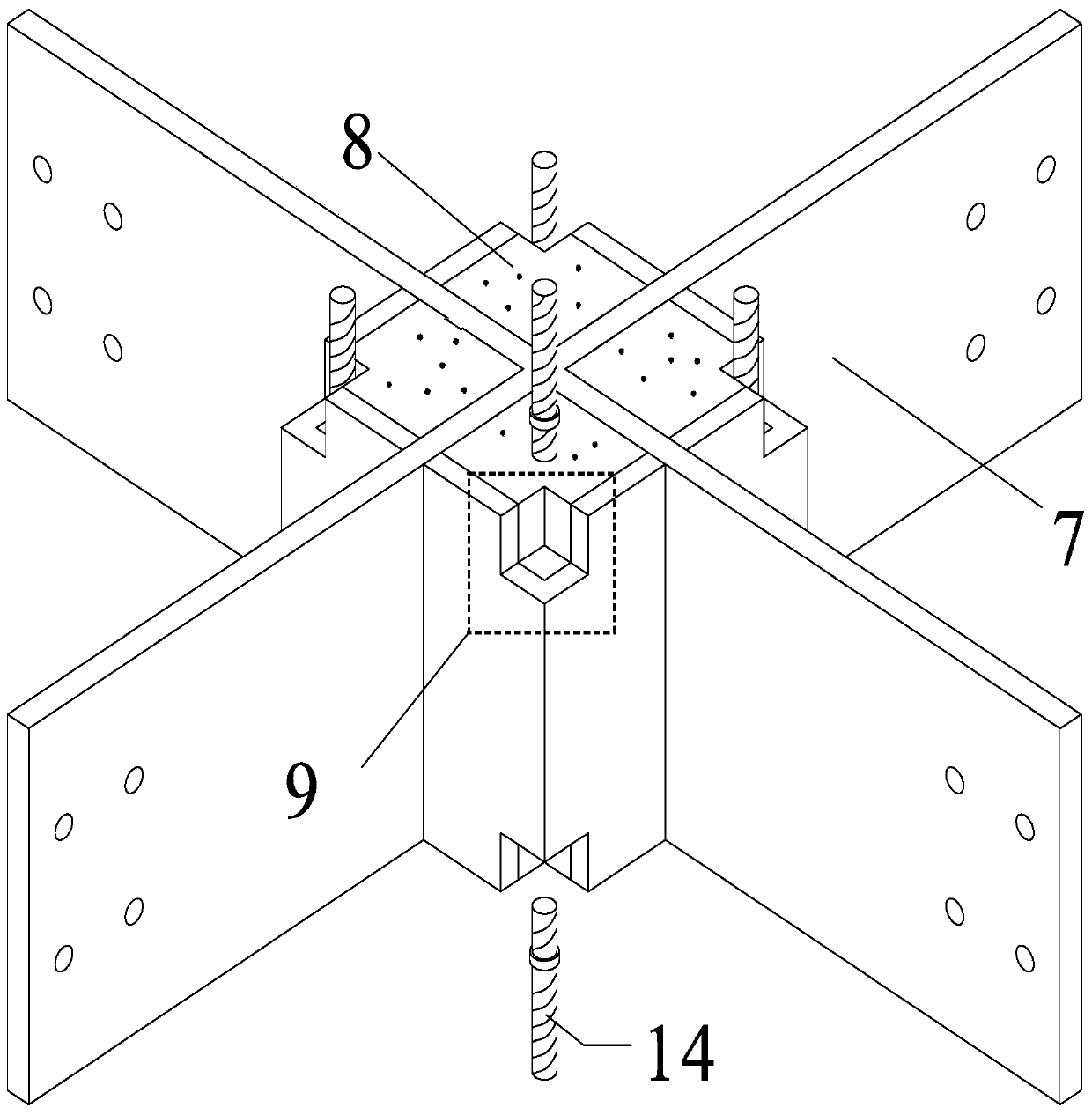

[0030] In this embodiment, a detachable steel beam-concrete steel tube column through-heart connection node, such as Figure 1-5 As shown, it includes a steel tube concrete column 1, an H-shaped steel beam 2, and a node domain 3. A flange ring plate 10 is provided at one end of the steel tube concrete column. Reinforcing ring plates 6 are provided above and below, steel pipes, vertical connecting plates and reinforcing ring plates are all fixed by welding, ultra-high performance concrete 8 is poured in steel pipes, flange ring plates are connected with reinforcing ring plates, four H Steel beams are fixed on the node domain in a cross shape. The vertical connecting plate includes two steel plates perpendicular to each other and fixed by welding, the vertical point of the vertical connecting plate is located in the steel pipe, and both sides of the two steel plates pass through the steel pipe. The reinforcing ring plate is provided with four overhanging sections 5, and two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com