Mechanical seal for agitated reactor stirring shaft

A technology of mechanical seals and stirring shafts, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of material pollution, troublesome disassembly and assembly, economic losses, etc., to reduce the difficulty of replacement, simple disassembly and assembly, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The mechanical seal for the stirring shaft of the reactor of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

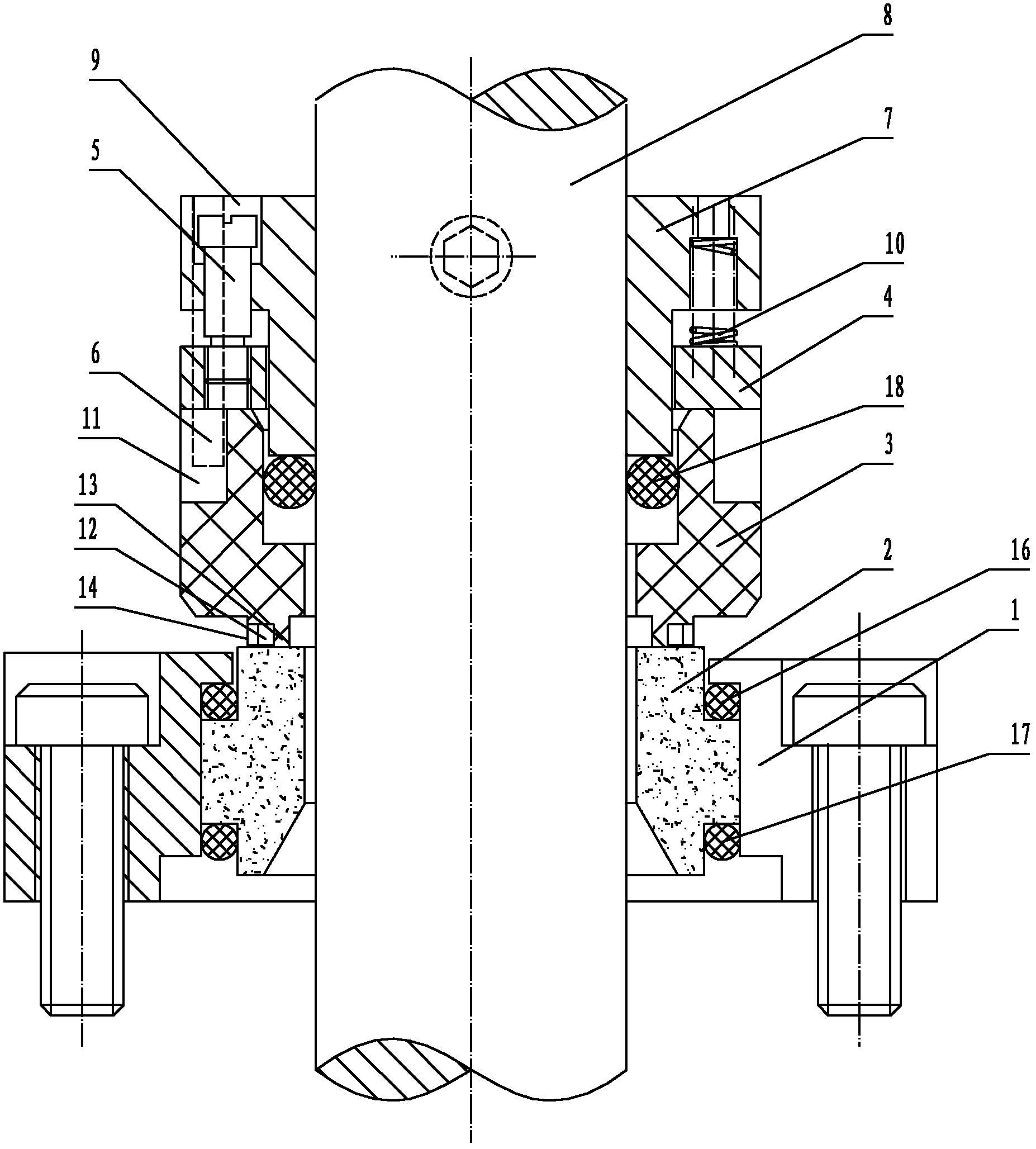

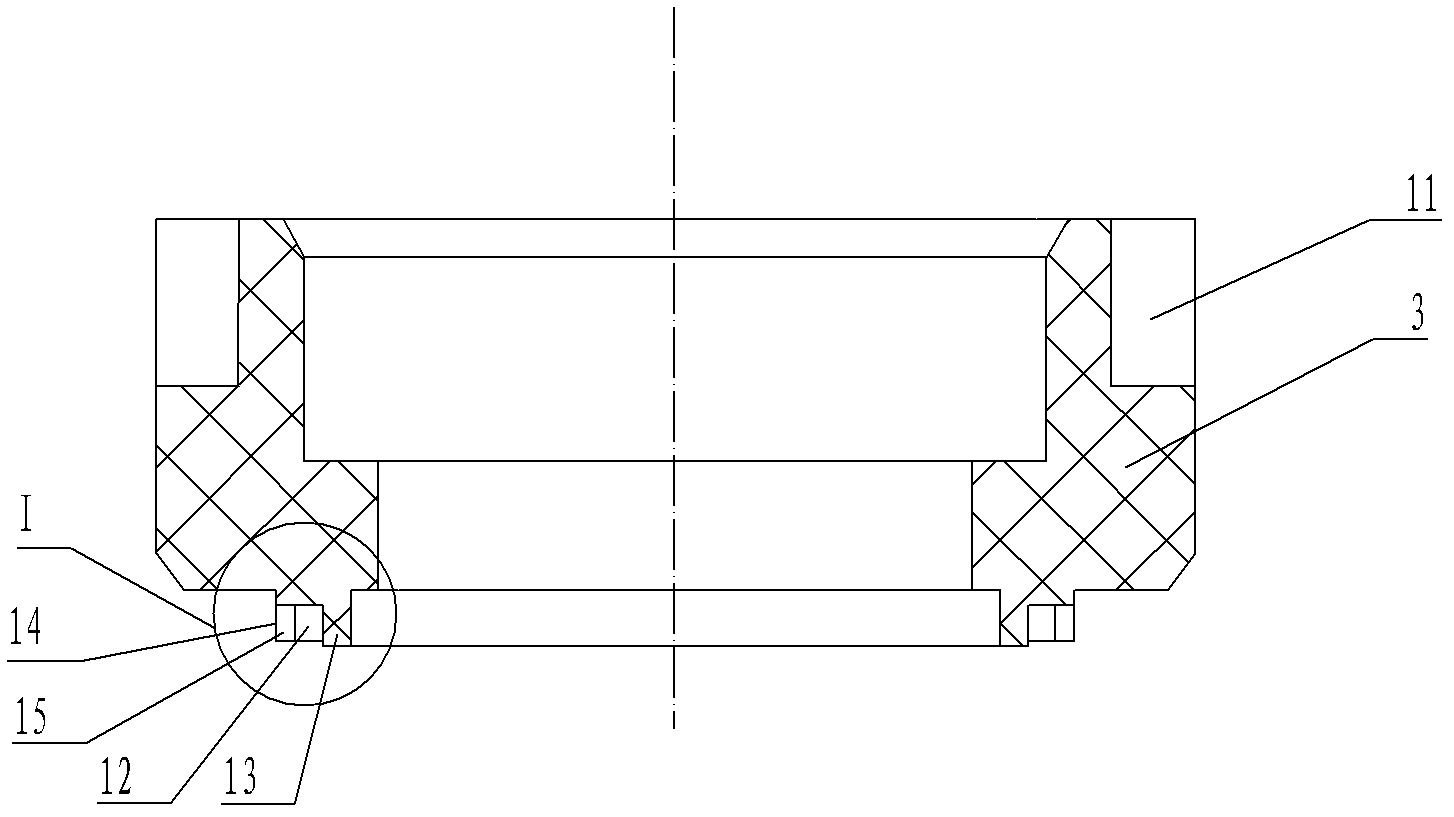

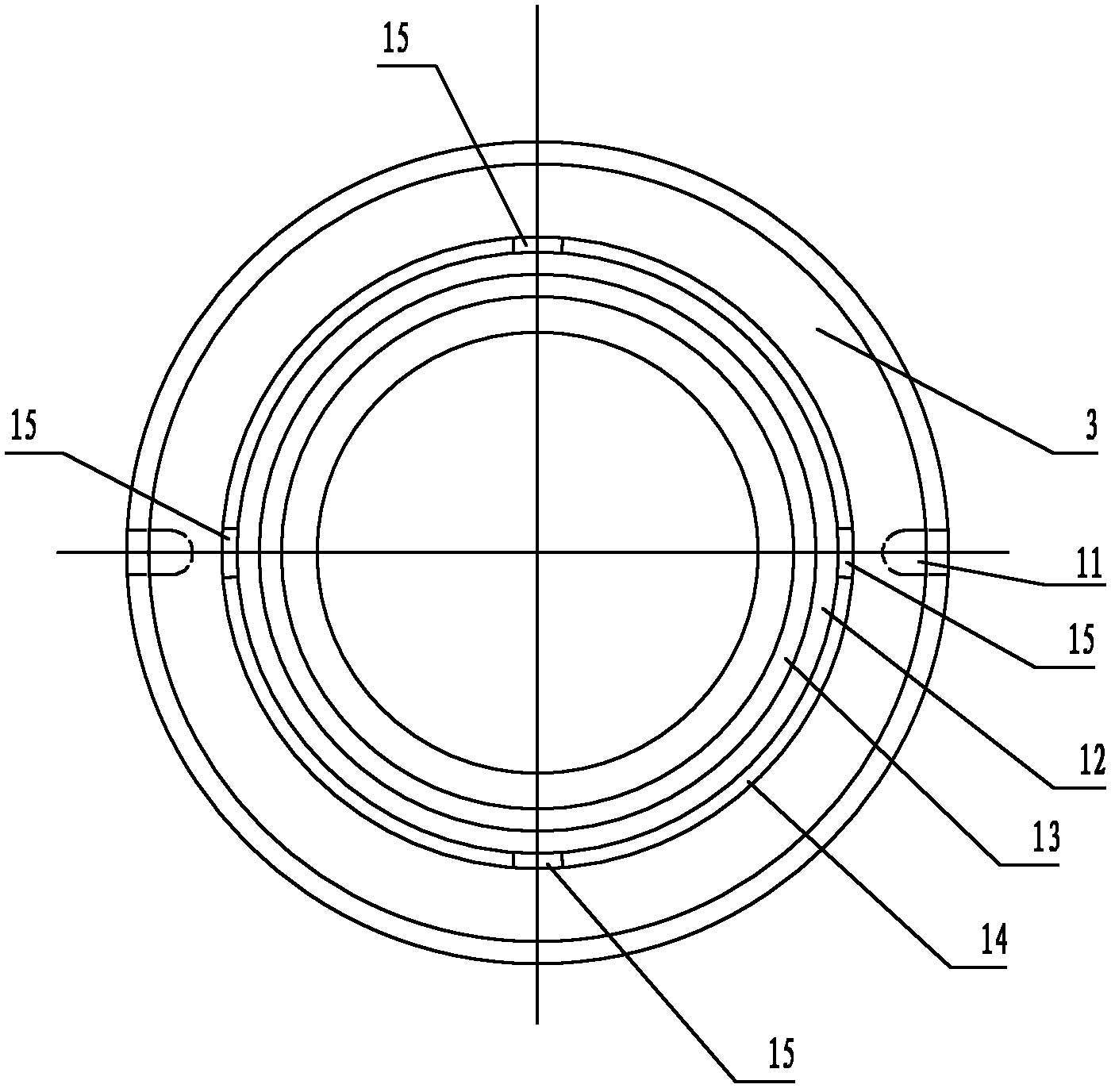

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, in this specific embodiment, the mechanical seal for the stirring shaft of the reaction kettle of the present invention includes a static ring seat 1, a static ring 2, a moving ring 3, a push ring 4, a transmission screw 5, a transmission pin 6, and a connection with the stirring shaft 8. The moving ring seat 7 and a number of springs 10 evenly distributed on the moving ring seat 7 in the circumferential direction, the push ring 4 is set on the moving ring seat 7, the transmission screw 5 is slidably inserted in the through hole 9 of the moving ring seat 7, and the transmission screw The lower end of 5 is connected with the push ring 4, the spring 10 is placed between the moving ring seat 7 and the pus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com