Leak detection method for electrical heating tube orifice of inner container of solar water heater

A solar water heater and electric heating technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems that are not suitable for mass industrial production and affect production efficiency, and achieve inspection Good leakage effect, improved production efficiency and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The leak detection method of the electric heating nozzle of the inner tank of the solar water heater comprises the following steps:

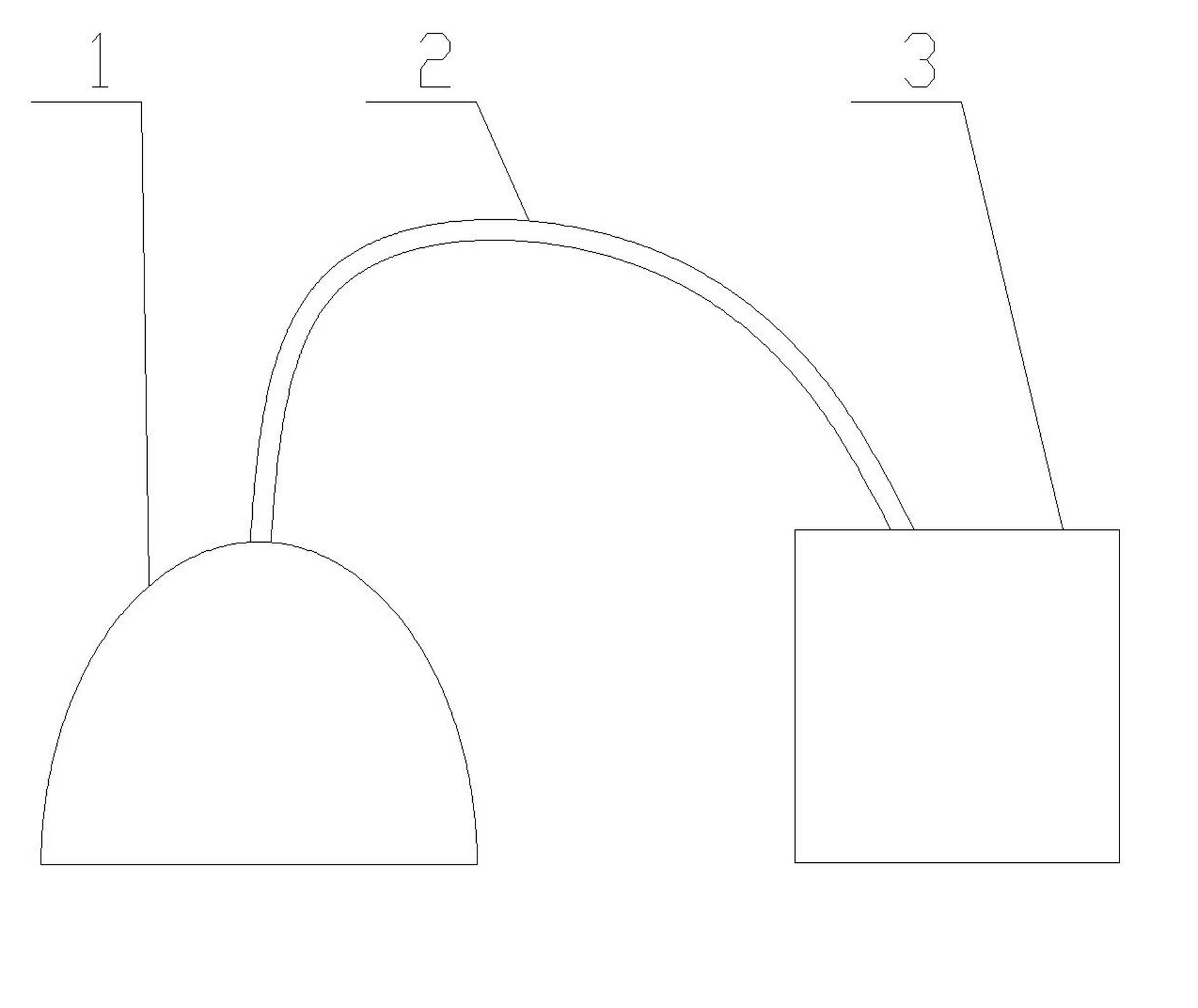

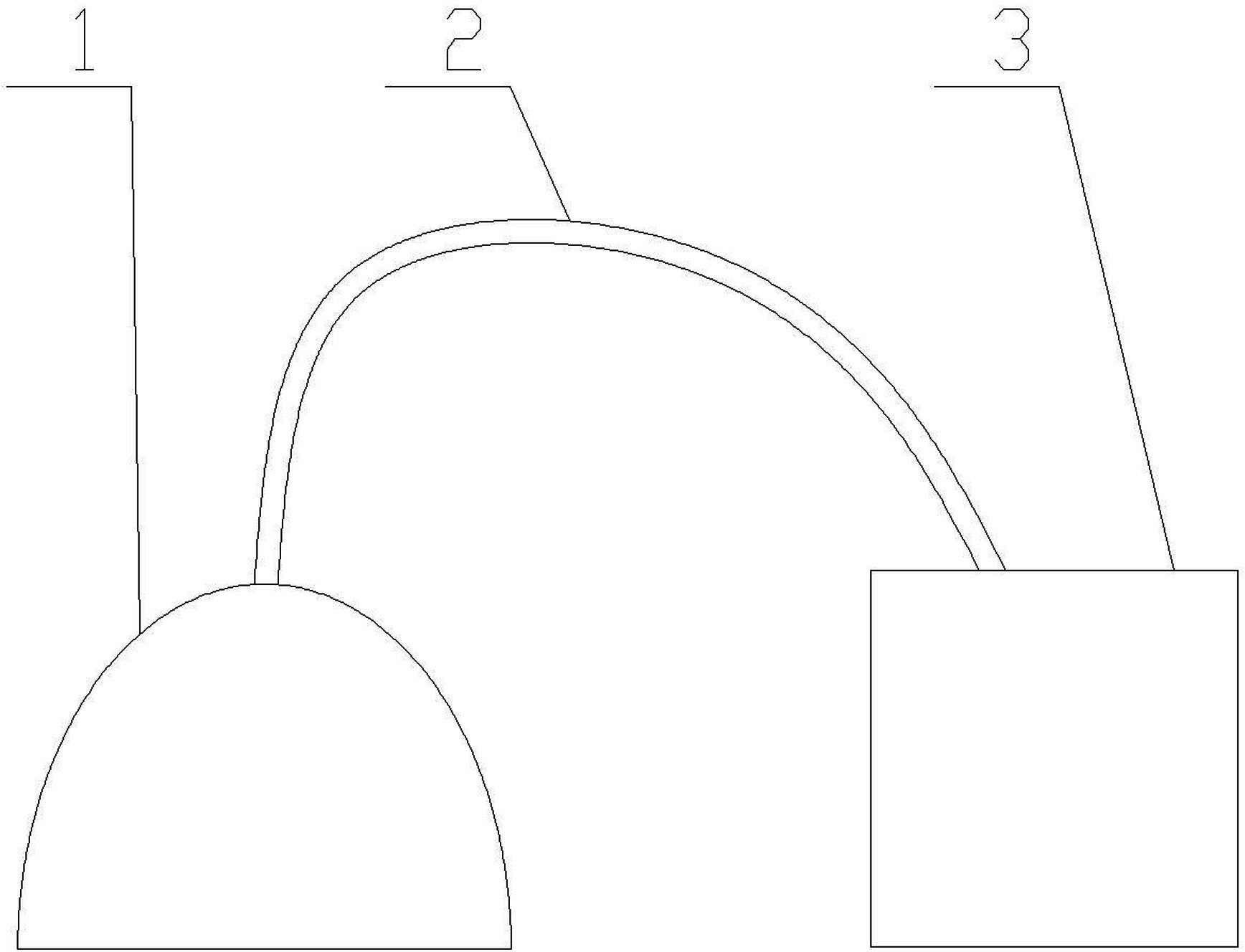

[0012] (1) Put a sealed tank 1 on the outer surface of the electric heating nozzle on the inner tank that has been installed with electric heating, and hold the sealed tank 1 with your hands.

[0013] (2) if figure 1 As shown, the sealed tank 1 is connected with a vacuum pump 3 through the air pipe 2, and the sealed tank 1 is evacuated by the vacuum pump 3, so that the sealed tank 1 is adsorbed on the inner liner, that is, the pressure difference between the outside and the inside of the sealed tank 1 is greater than its gravity.

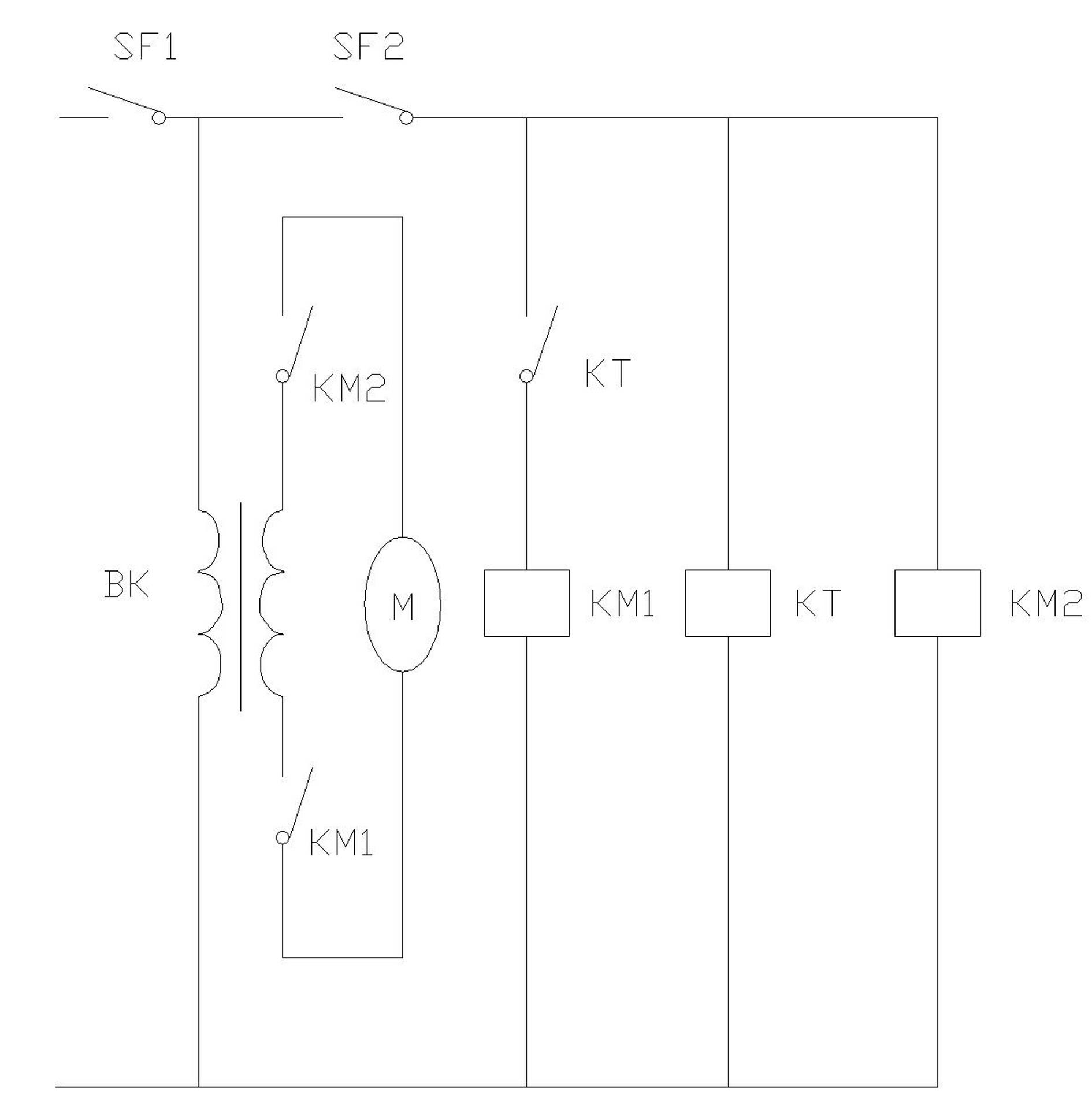

[0014] The vacuum pump 3 is connected as figure 2 The shown controller includes transformer BK, air switch SF1, foot switch SF2, time relay KT, relay KM1 and relay KM2. The output end of the transformer BK, the working circuit of the relay KM1, the working circuit of the relay KM2 and the motor M of the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com