Plane magnetic integrated electro magnetic interference (EMI) filter

A magnetic integration and filter technology, applied in the direction of inductance with magnetic core, structural fixed capacitor combination, transformer/inductor coil/winding/connection, etc. problems, to achieve the effect of good consistency, high power density, and production standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

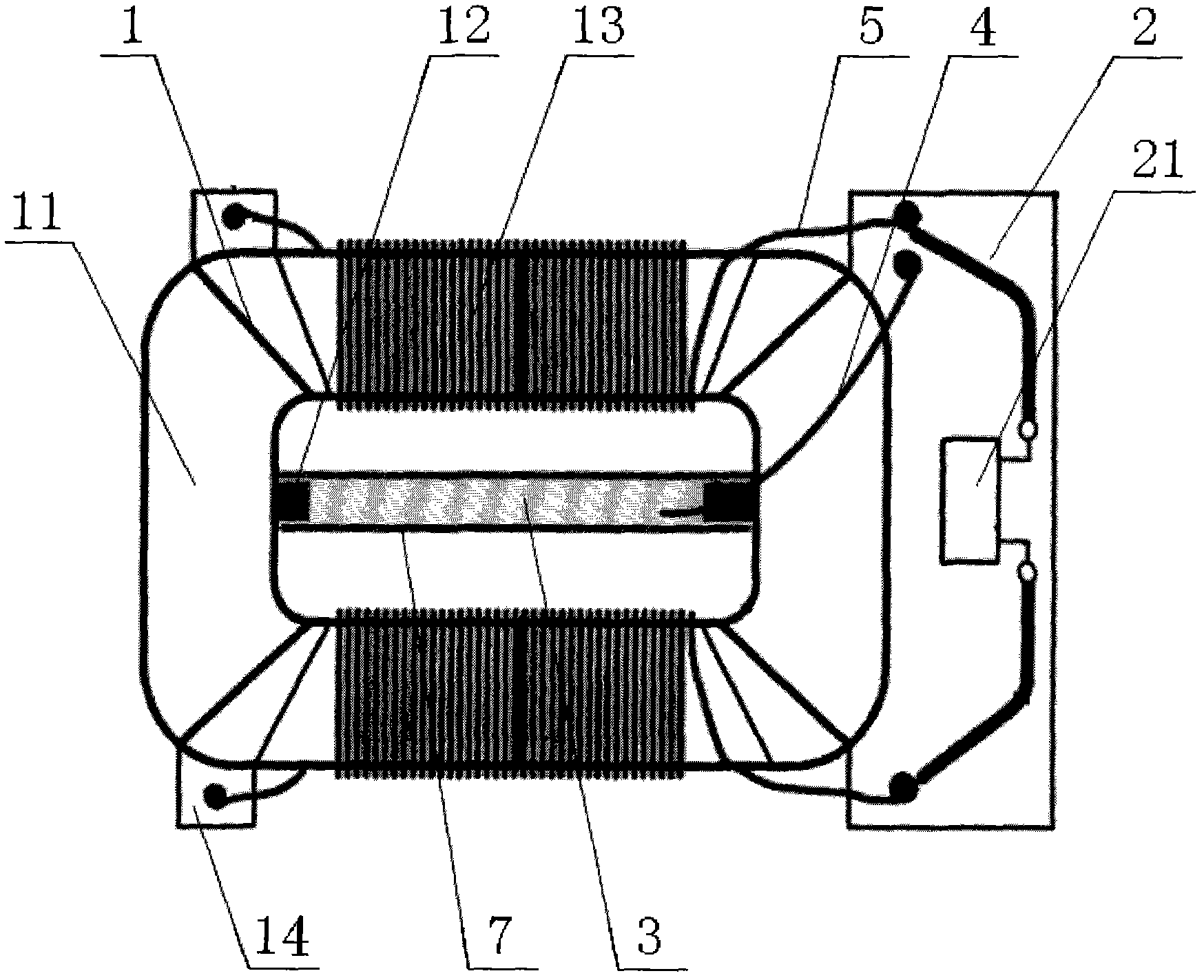

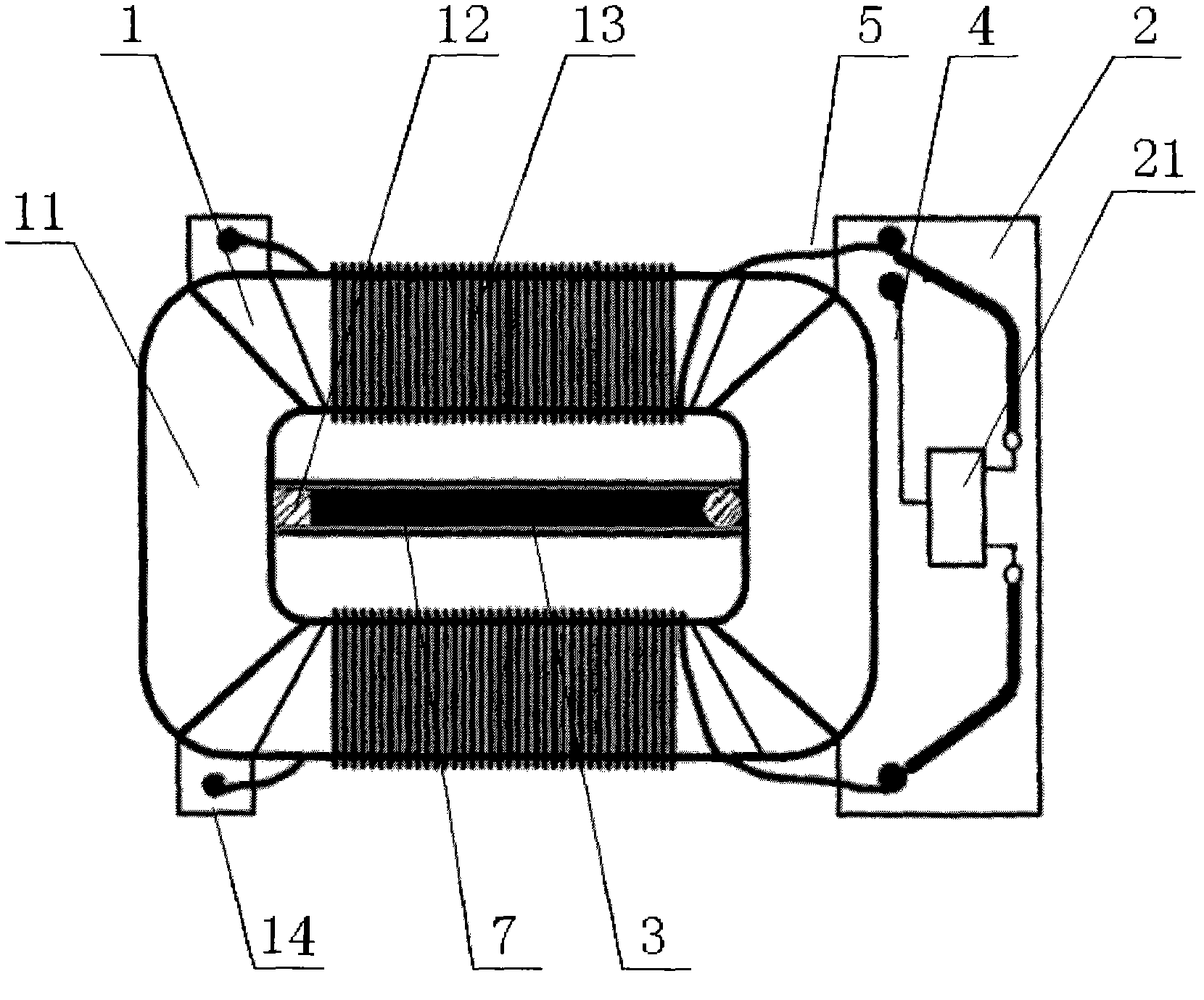

[0033] Please refer to the attached Figure 1 to Figure 11 As shown, the present invention is a planar magnetic integrated EMI filter, which is composed of a planar magnetic integrated common mode inductor 1, a PCB board 2 welded with a differential mode capacitor or a common mode capacitor 21, a non-magnetic metal shell 3, and a grounding lead The terminal 4, the inductor terminal 5 and the base plate 6 are composed of several parts. Among them, attached figure 1 The planar magnetic integrated EMI filter in uses differential mode capacitors 21, attached figure 2 The planar magnetic integrated EMI filter in uses common-mode capacitors 21.

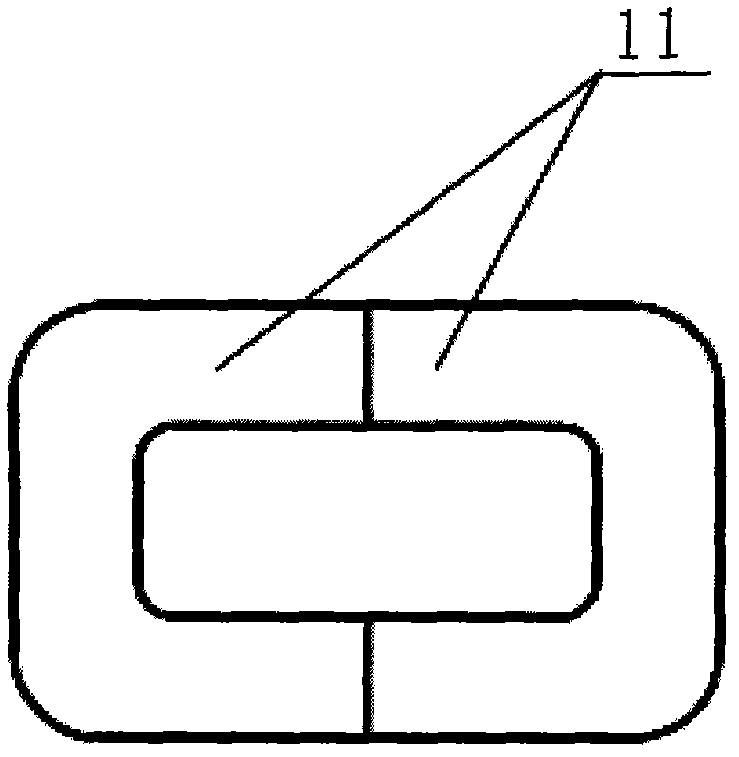

[0034] The planar magnetic integrated common mode inductor 1 includes a pair of U-shaped magnetic cores 11 and a cylindrical or square bar-shaped magnetic core 12 located between the pair of U-shaped magnetic cores 11 . Wherein, the U-shaped magnetic core 11 is specifically made of U-shaped magnetic cores made of ferrite soft magnetic, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com