High-strength gas discharge lamp inductive ballast

A technology for gas discharge lamps and inductive ballasts, applied in the direction of inductors, transformers/inductor cores, circuits, etc., can solve the problems of low production efficiency, high cost, complex process, etc., and reduce copper resistance loss and heat generation. Reduce, reduce the effect of magnetic flux saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The inductive ballast for high-intensity gas discharge lamps of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

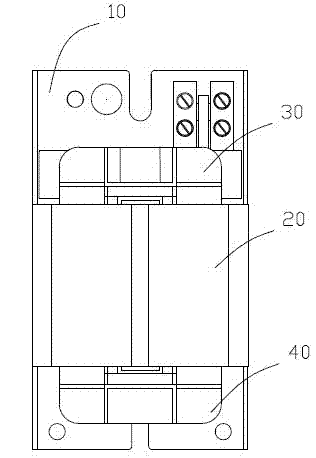

[0017] Such as figure 1 As shown, an inductive ballast for high-intensity gas discharge lamps in one embodiment includes a bottom plate 10, an iron core 20 fixed on the bottom plate 10, a skeleton 30 and a skeleton 40, and a coil wound on the iron core 20 through the skeleton 30, 40 (picture not viewed).

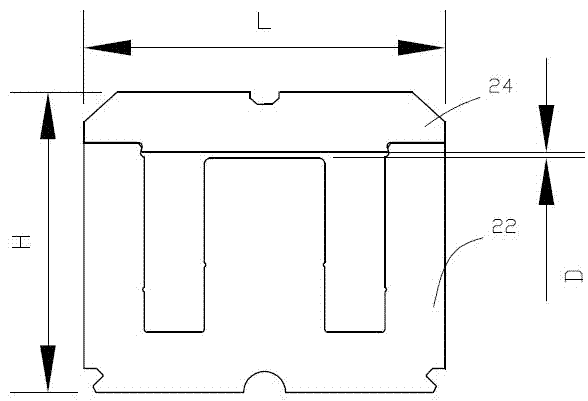

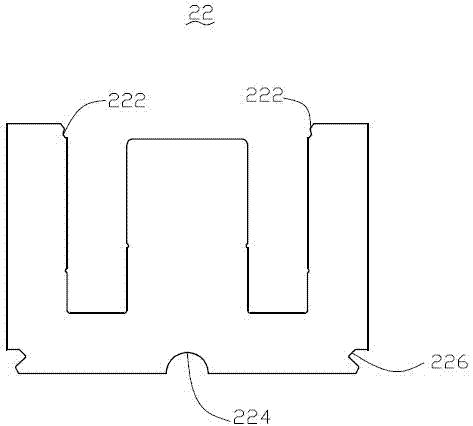

[0018] Such as figure 2 As shown, in this embodiment, the iron core 20 adopts an E-shaped iron core 22 and an I-shaped iron core 24 formed by laminating a plurality of E-shaped and I-shaped silicon steel sheets. The cross-section of the iron core 20 is roughly square, and the ratio of its height H to width L is about 5:6. This ratio minimizes the copper resistance loss of the coil and the iron loss of the iron core, and greatly reduces the heat generation of the ballast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com