Automatic fruit segmenting and stoning machine

An automatic and valve-breaking technology, applied in fruit de-pitting devices, food science, applications, etc., can solve the problems of easy damage to knives, reduced product quality and production efficiency, and rough fruit pits, so as to improve productivity and improve product quality. The effect of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

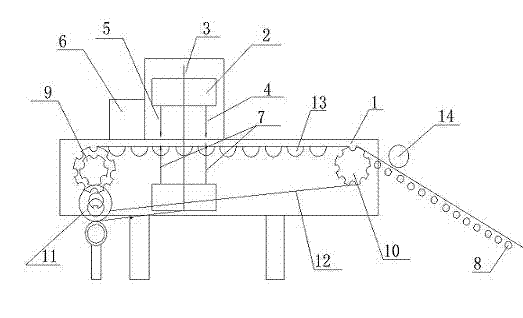

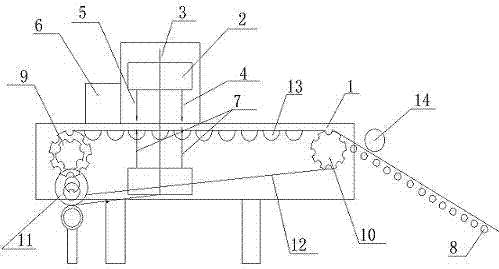

[0012] Such as figure 1 As shown, the fruit automatic petal-breaking and core digging machine of the present invention includes a body 1, a head box 2, a guide shaft 3, a control box 6 and a transmission mechanism, and the transmission mechanism is installed in the body 1, and the control box 6 and the head box 2 Set on the upper part of the body 1, the guide shaft 3 is connected between the head box 2 and the body 1, the front group blade 4, the rear group blade 5 and the fork rotary knife 7 are installed on the lower part of the head box 6, and the upper side of the body 1 is installed on the outside The material roller 8, the upper part of the body 1 is provided with a tray 13, and the transmission mechanism includes a driving transmission wheel 9, a driven transmission wheel 10, a large gear concave-convex wheel 11 and a transmission chain 12, and the driving transmission wheel 9 and the large gear concave-convex wheel 11 mesh, and the transmission chain 12 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com