Rolling device for building translation engineering and using method thereof

A rolling device and building technology, applied in building construction, construction, building maintenance, etc., can solve the problems of large frictional reaction force between steel plates, high requirements for loading equipment, and increased friction coefficient, so as to achieve unfavorable damage and low cost. The effect of low, horizontal dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

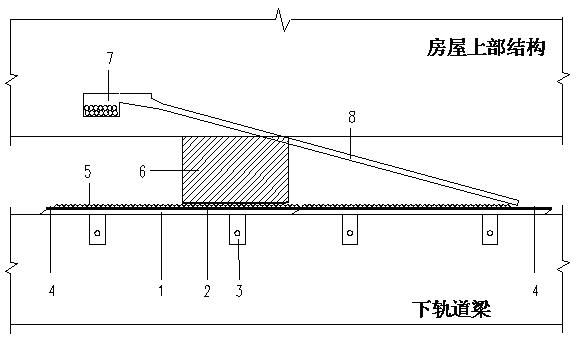

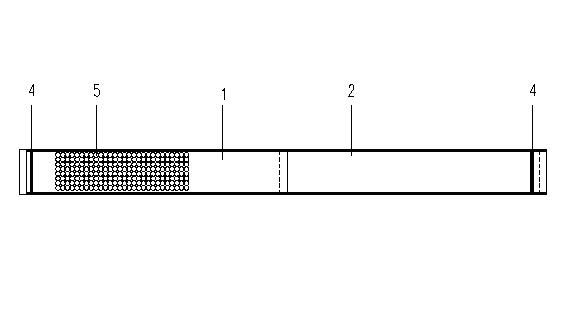

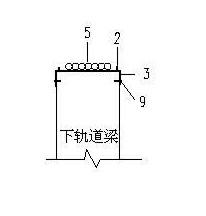

[0025] As shown in the figure, a rolling device used in building translation engineering has a steel plate 1 laid on the lower track beam, and full balls 5 laid on the steel plate 1, so that the slider 6 can move on the balls 5, and the balls transmit The pipe 8 is fixed on the upper structure of the house. The balls 5 in the ball basket 7 can reach the front of the upper slider 6 of the steel plate 1 along the ball transmission pipe 8. The upper left and right sides of the steel plate 1 are provided with lateral limit bars 2, and the lower part passes through the steel plate. The fixing strip 3 fixes the steel plate 1, the steel plate 1 is provided with grooves front and back, and two transverse limit strips 4 are arranged at the grooves.

[0026] The steel plate 1 in the present invention is a plurality of steel plate layers combined into any long track, wherein the length of each steel plate is 0.5-3m, and the width is the same as that of the lower track beam. The diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com