Cylinder driven returning mechanism for side flanging and side reshaping of automobile mold

A cylinder-driven, automotive mold technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as cost increase, processing and debugging difficulties, etc., and achieve the effects of compactness and reasonableness, convenient application and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

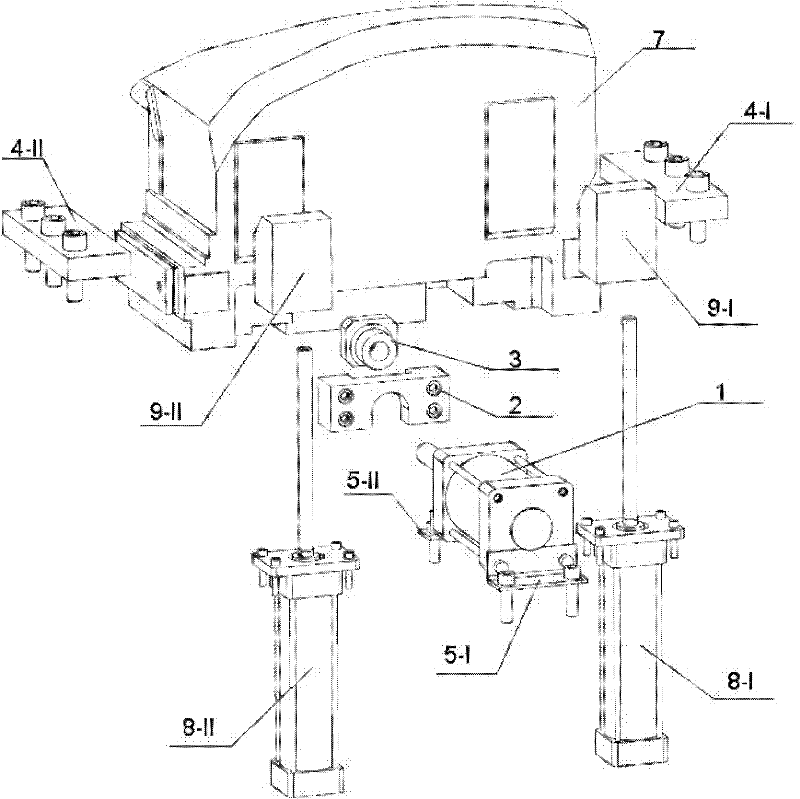

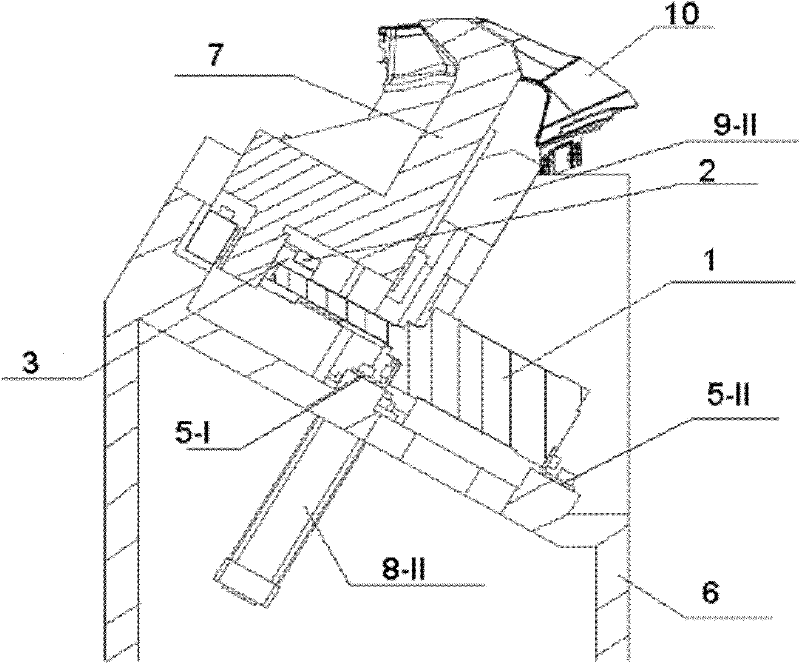

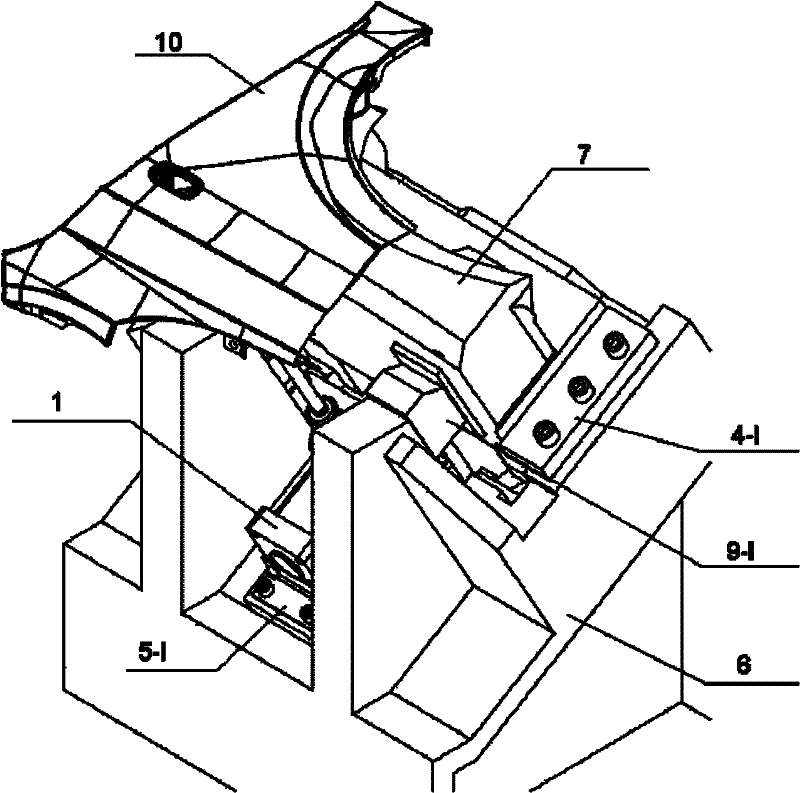

[0017] A cylinder-driven return mechanism for shaping the side flanging of an automobile mold is composed of a driving cylinder part and an auxiliary cylinder part. The driving cylinder part includes a driving cylinder 1, a snap ring 2, a cylinder joint 3 and two guide cover plates 4- I, II, the end of the piston rod of the driving cylinder 1 is provided with a section of external thread, the driving cylinder 1 is fixed and installed on the lower die body 6 through two tripod-type connecting plates 5-I, II and fixed with screws, and the snap ring 2 is a rectangular One side of the snap ring 2 is provided with a rectangular groove, the middle and lower part of the corresponding side is provided with a U-shaped groove with an opening downward, the four corners of the side are provided with four screw holes, and the snap ring 2 uses The four screw holes are fixed on the bottom surface of the pulley 7 by screws. The cylinder joint 3 is a convex cylinder with a rectangular end face....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com