Method for reducing sliding distance of airplane during landing and taking off

A technology for taking off and taxiing distance of an aircraft, applied in the direction of the parking device, etc., can solve the problems of shortening the use distance of the runway, difficult operation, and small take-off load of the aircraft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

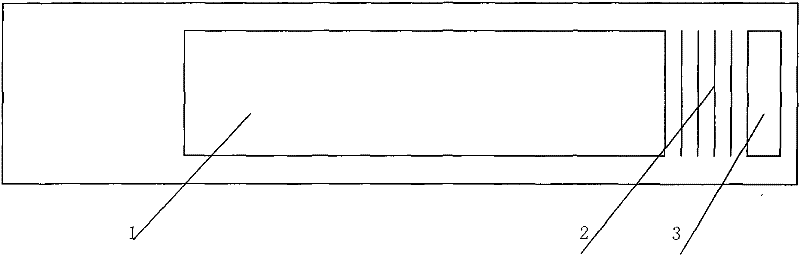

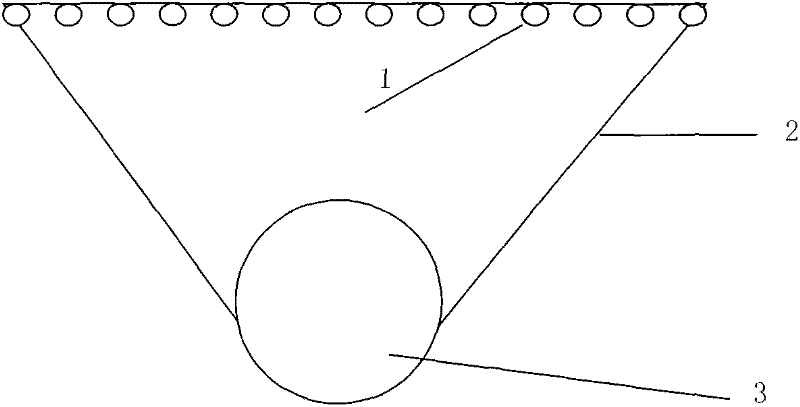

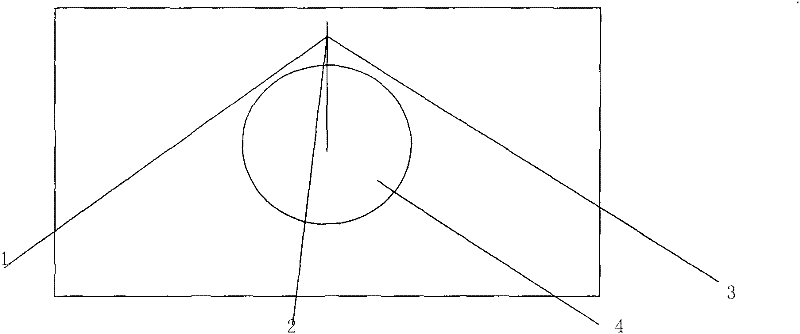

[0013] Take the takeoff data of a certain plane as an example ( Figure 4 ),From Figure 4 It can be seen that when the aircraft raises the front wheel speed (VR speed), it needs to glide 400 meters and the speed reaches 284 km / h (79 m / s), while when glide 300 meters, the speed only reaches 93 km / h (26 m / s) , The distance to VR speed is only 100 meters. During the experiment, the aircraft is placed on the conveyor belt, the auxiliary towing rope and the towing rope are connected with the aircraft, the aircraft starts and accelerates, and the transmission belt starts and accelerates in the reverse direction. At this time, the tires of the aircraft rotate together with the transmission belt. / Hour (26m / s), the aircraft is equivalent to reaching a speed of 93km / h (26m / s) after taxiing 300 meters on the runway. At this time, the transmission belt is decelerated, the auxiliary towing cable and the towing cable After falling off from the aircraft in turn, the aircraft will quickly slid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull | aaaaa | aaaaa |

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com