Superfine YG type hard alloy containing light-heavy rare earth and preparation method thereof

A cemented carbide, light and heavy rare earth technology, applied in the field of ultra-fine cemented carbide preparation, to achieve the effect of easy implementation, saving investment and energy consumption, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

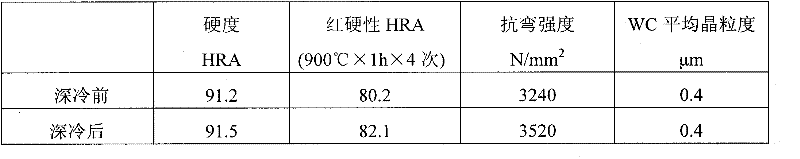

Examples

Embodiment 1

[0017] The ultra-fine YG type hard alloy containing light and heavy rare earth composite additives is characterized in that the components of the hard alloy are: WC hard phase, Co binding phase and composite rare earth additives. The mass of WC hard phase accounts for 91% of cemented carbide, the mass of Co binder phase accounts for 8% of cemented carbide, the mass of light rare earth La, Ce, Nd accounts for 0.6% of cemented carbide, and the mass of heavy rare earth Dy, Y The mass accounts for 0.4% of the cemented carbide.

[0018] A method for preparing ultra-fine YG-type cemented carbide containing light and heavy rare earth composite additives, the method steps are: after weighing various powder raw materials according to weight percentage, put the prepared powder raw materials into a high-energy ball mill for grinding, and the ball-to-material ratio is 10:1, using alcohol as the ball milling medium, adding paraffin, ball milling for 72 hours, drying and granulating into a ...

Embodiment 2

[0020] The ultra-fine YG type hard alloy containing light and heavy rare earth composite additives is characterized in that the components of the hard alloy are: WC hard phase, Co binding phase, grain growth inhibitor, and composite rare earth additive. The quality of the WC hard phase accounts for 90% of the cemented carbide, the quality of the Co binder phase accounts for 8% of the cemented carbide, and the grain growth inhibitors VC and Cr 3 C 2 The quality of TaC accounts for 1% of the cemented carbide, and the light rare earth La 2 o 3 , CeO 2 、Nd 2 o 3 The mass accounts for 0.6% of cemented carbide, heavy rare earth Y 2 o 3 The mass accounts for 0.4% of the cemented carbide.

[0021] A method for preparing ultra-fine YG-type cemented carbide containing light and heavy rare earth composite additives, the method steps are: after weighing various powder raw materials according to weight percentage, put the prepared powder raw materials into a high-energy ball mill fo...

Embodiment 3

[0023] The ultra-fine YG type hard alloy containing light and heavy rare earth composite additives is characterized in that the components of the hard alloy are: WC hard phase, Co binding phase, grain growth inhibitor, and composite rare earth additive. The mass of the WC hard phase accounts for 88% of the cemented carbide, the mass of the Co binder phase accounts for 10% of the cemented carbide, and the grain growth inhibitors VC and Cr 3 C 2 , The quality of TaC accounts for 1% of the cemented carbide, light rare earth CeO 2 、Nd 2 o 3 、Sm 2 o 3 The mass accounts for 0.6% of the cemented carbide, the heavy rare earth Dy 2 o 3 , Y 2 o 3 The mass accounts for 0.4% of the cemented carbide.

[0024] A method for preparing ultra-fine YG-type cemented carbide containing light and heavy rare earth composite additives, the method steps are: after weighing various powder raw materials according to weight percentage, put the prepared powder raw materials into a high-energy bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap