Plugin pipeline mounting structure

An installation structure and plug-in technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of troublesome installation operation, low assembly efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

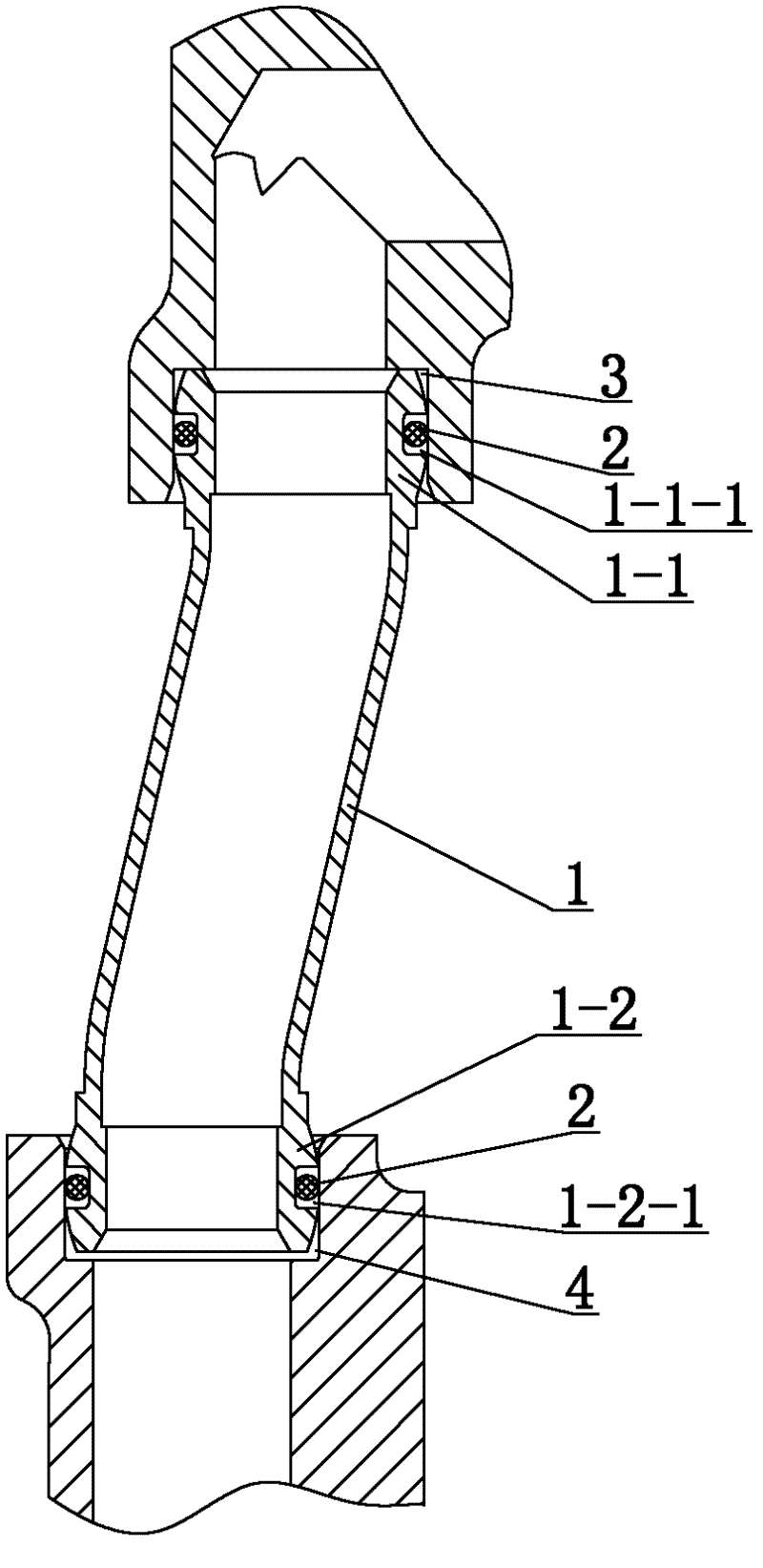

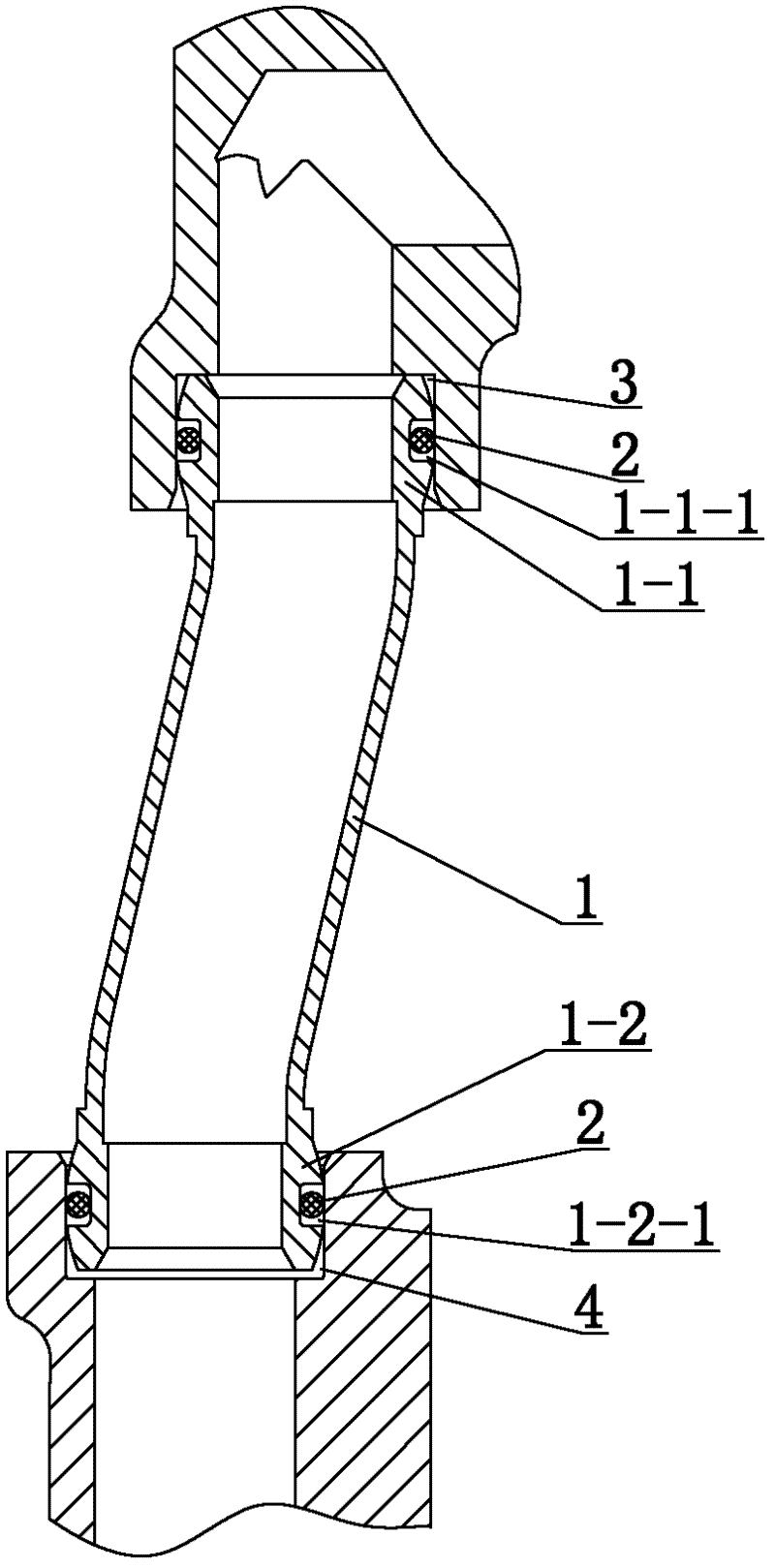

[0015] see figure 1 , a plug-in pipeline installation structure, including a first plug part 1-1 and a second plug part 1-2 integrally arranged at both ends of the pipeline 1, the outer contours of the first plug part and the second plug part The surfaces are provided with annular grooves, specifically, a first annular groove 1-1-1 is provided on the first plug part, a second annular groove 1-2-1 is provided on the second plug part, and a second annular groove 1-2-1 is provided on the annular groove A sealing ring 2 is installed inside, and the sealing ring can adopt an O-shaped rubber ring. A first installation hole 3 and a second installation hole 4 are respectively provided on the connectors at both ends, and the first plug part and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com