Storage battery lift truck driving motor braking apparatus

A technology for driving motors and braking devices, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of lowering the working efficiency of lift trucks, prone to overshooting, and difficult installation of motors, so as to save manpower and improve work efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The braking device for driving the motor of the battery lift car of the present invention will be further described in detail through specific embodiments below.

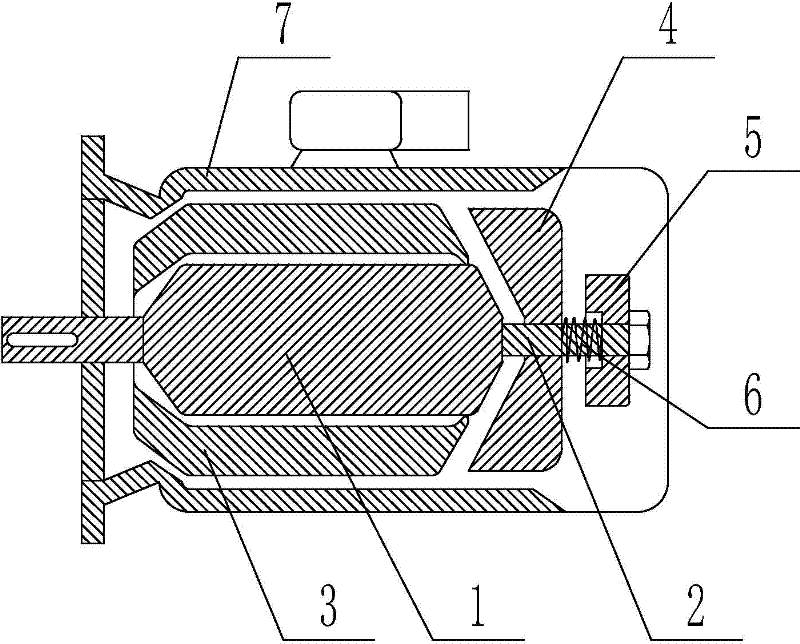

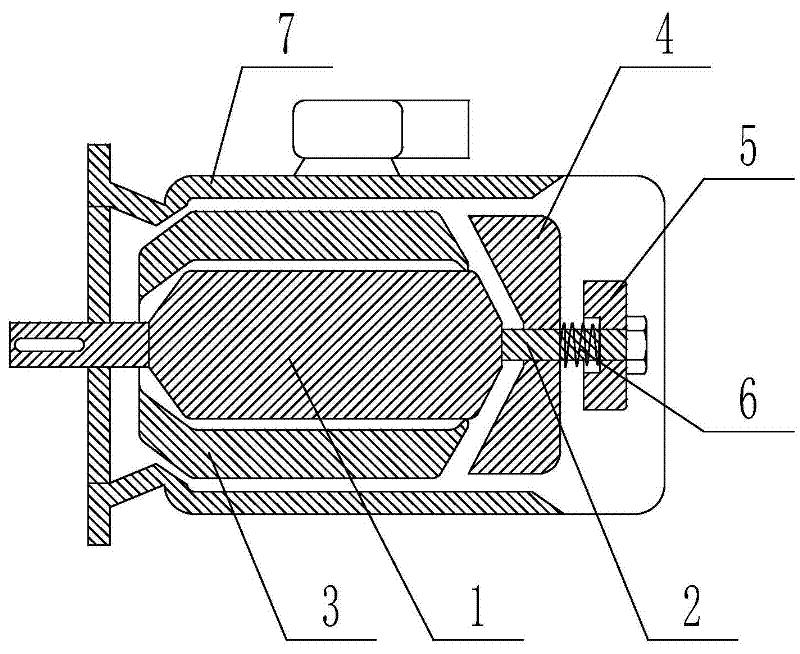

[0013] like figure 1 As shown, the motor brake device driven by the battery lift car includes an elongated shaft 2 arranged at the rear end of the rotor 1 of the motor and a stator 3 sleeved outside the rotor 1 of the motor. The elongated shaft 2 is sequentially provided with cones Shaped iron 4 and electromagnet 5, spring 6 is arranged between conical iron 4 and electromagnet 5, and described extension shaft 2, stator 3, conical iron 4, electromagnet 5 and spring 6 are all arranged on the motor Shell 7.

[0014] The working principle of the present invention is: when the motor is energized and needs to run, the electromagnet 5 is energized to generate magnetism to absorb the conical iron 4. At this time, the spring 6 is in a compressed state, and the stator 3 rotates synchronously with the rotor 1 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com