Permanent magnet brushless DC (direct current) motor

A permanent magnet brushless DC and magnetic steel technology, applied in the field of electric motors, can solve problems such as low production efficiency, increased production cost, and complicated installation of rotor magnetic steel, so as to increase motor efficiency, reduce phase current, and adjust positive and negative The effect of convenient current transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

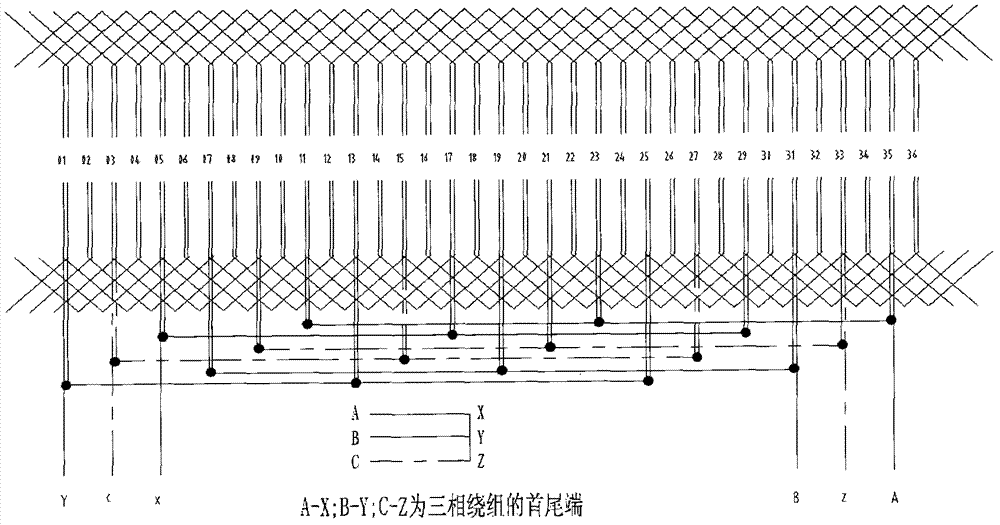

[0020] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

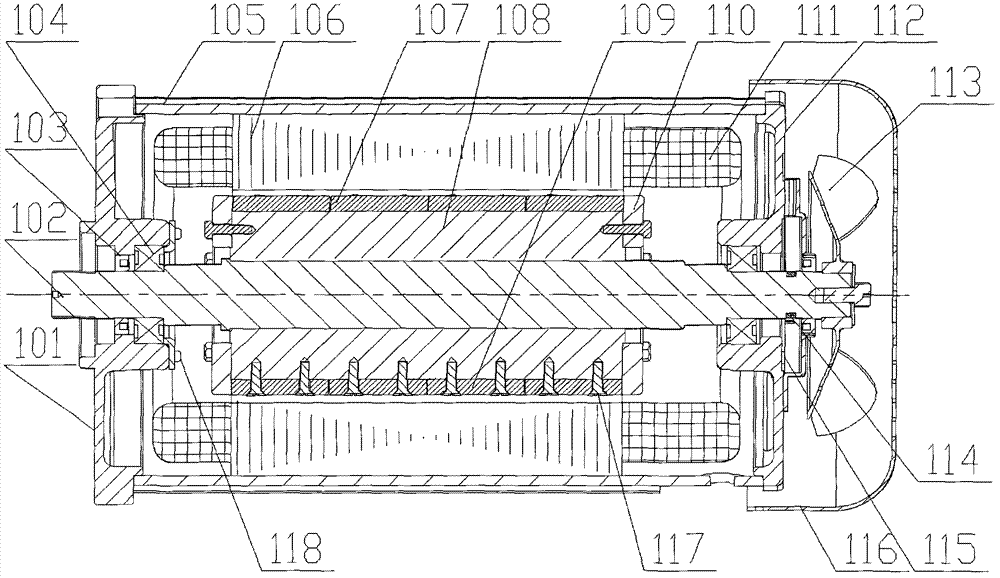

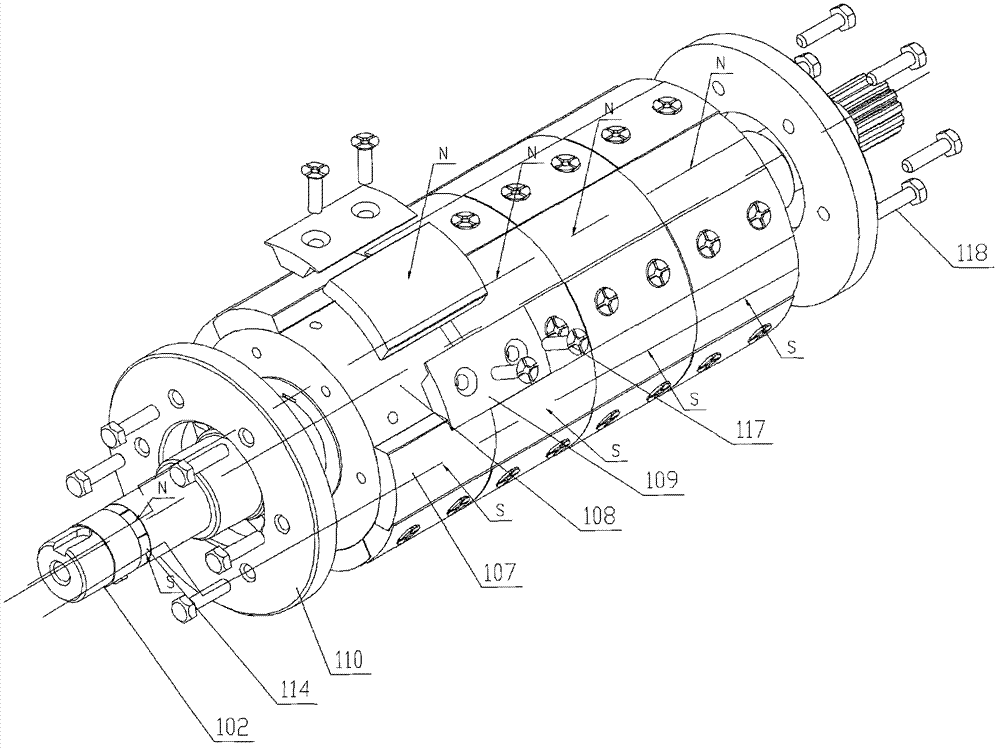

[0021] Such as figure 1 As shown, the permanent magnet brushless DC motor includes a front end cover 101, a rear end cover 112, a casing 105, a stator, a rotor, and a Hall sensor element circuit board 115, wherein the casing 105, the front end cover 101, and the rear end cover 112 constitutes as the supporting point of the whole motor. The stator core 106 is housed in the casing 105 . Wherein, the rotor includes a rotor shaft 102, a rotor yoke 108, a magnetic steel 107, a magnetic steel baffle 110, and a magnetic steel partition 109. In the embodiment of the present invention, the rotor yoke 108 does not have a rotor punch, which can be directly made of Low-carbon steel (such as 20 round steel, A3 steel, etc.), the magnetic steel 107 is fixed on the outer circumference of the rotor yoke 108 and blocked by the magnetic steel baffles 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com