Drum-type distributed winding axial hybrid excitation motor

A technology of distributed winding and axial mixing, applied in the shape/style/structure of winding conductors, magnetic circuits, electromechanical devices, etc., can solve the problems that it is difficult to achieve the torque density level of synchronous excitation motors and the low utilization rate of iron cores, and achieve The effect of reducing the risk of demagnetization, increasing the slot full rate, and improving the efficiency and power density of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

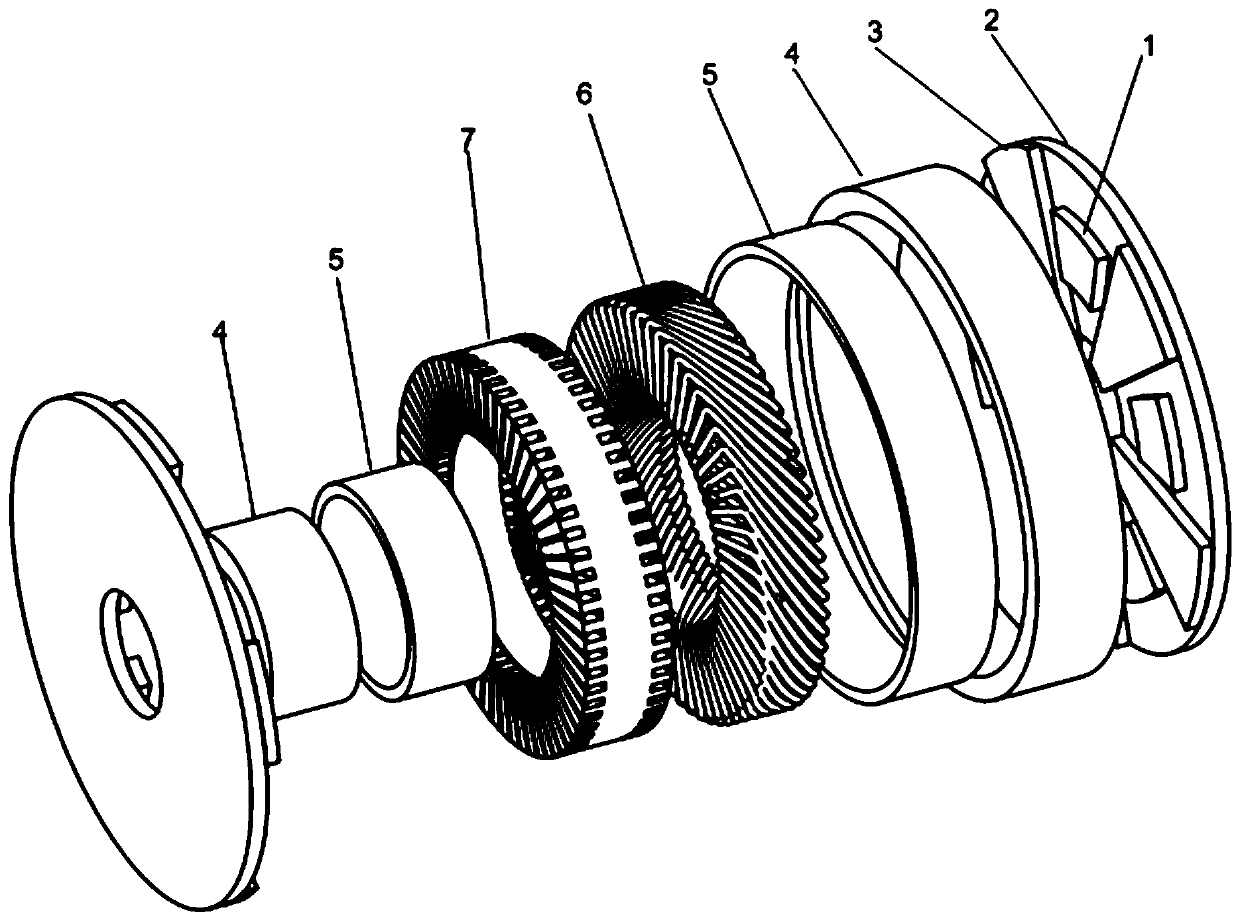

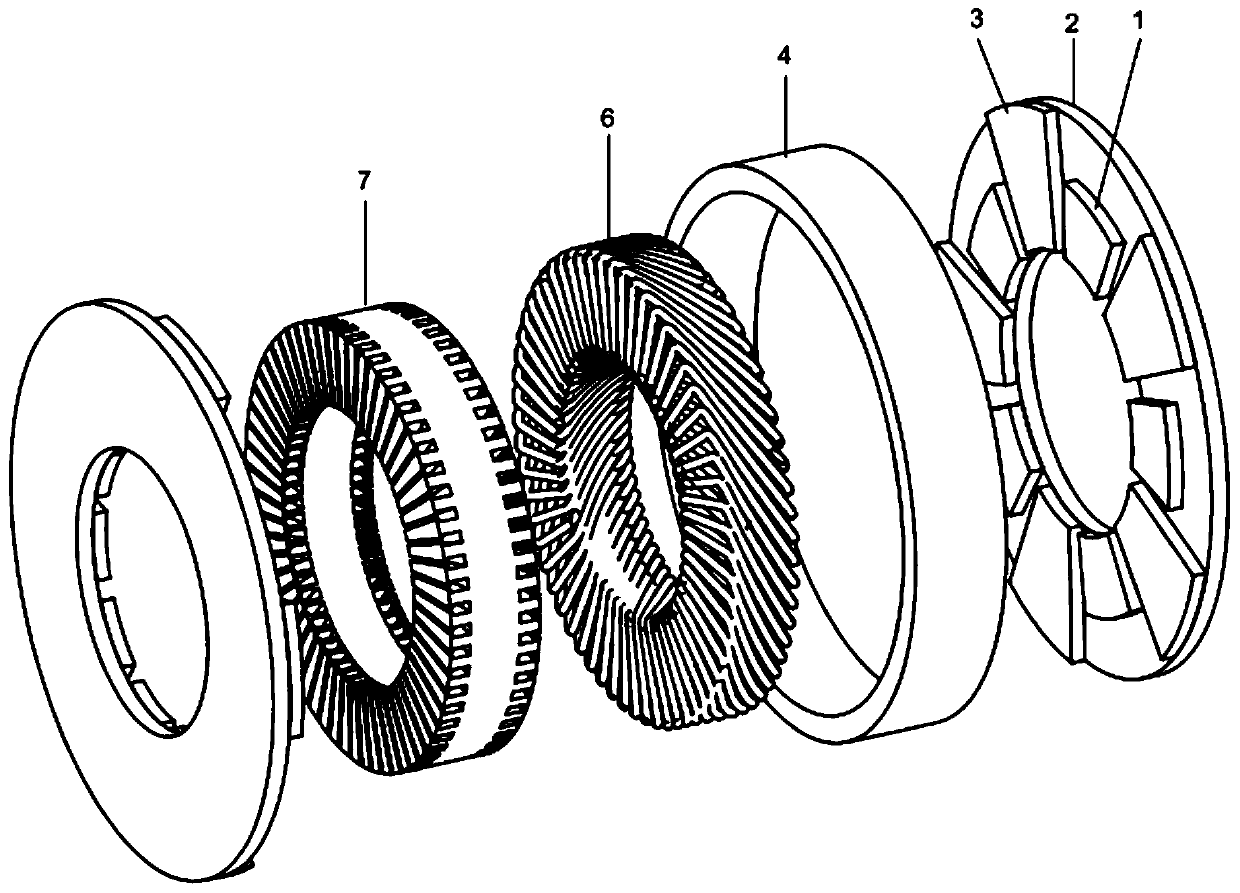

[0040] combine figure 1 , the drum-type distributed winding axial hybrid excitation motor of the present invention includes a stator disk and two rotor disks, wherein the stator disk includes a stator core 7, an armature winding 6, an excitation winding 5 and a magnetic conduction ring 4, and the rotor disk includes a rotor back Yoke 2, magnetic pole piece 3 and permanent magnet 1.

[0041] Further, combine figure 1 , is a double-ended excitation drum-type distributed winding axial hybrid excitation motor, the armature winding 6 is installed on the magnetic yoke of the stator core 7, and the two excitation windings 5 are respectively installed on the inner ring and outer ring of the armature winding 6 circle, two magnetically permeable rings 4 are correspondingly installed inside and outside the field winding 5;

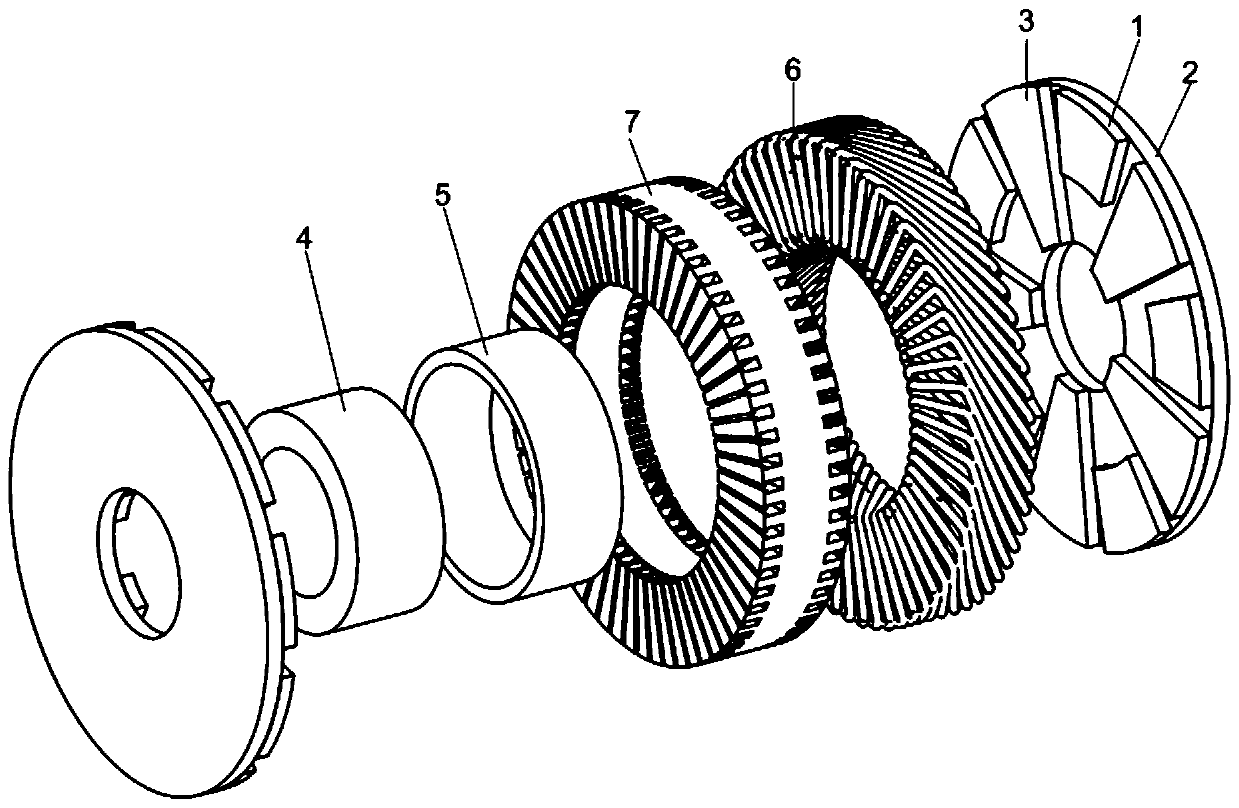

[0042] combine figure 2 , is an internally excited drum type distributed winding axial hybrid excitation motor, the armature winding 6 is installed on the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com