Flux switching type linear rotary permanent magnet actuator

A magnetic flux switching and actuator technology, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, magnetic circuit characterized by magnetic materials, etc., can solve the large volume and weight of the two-degree-of-freedom drive mechanism , large system error, low positioning accuracy and other problems, to achieve the effect of facilitating mass production, good magnetic effect, and improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

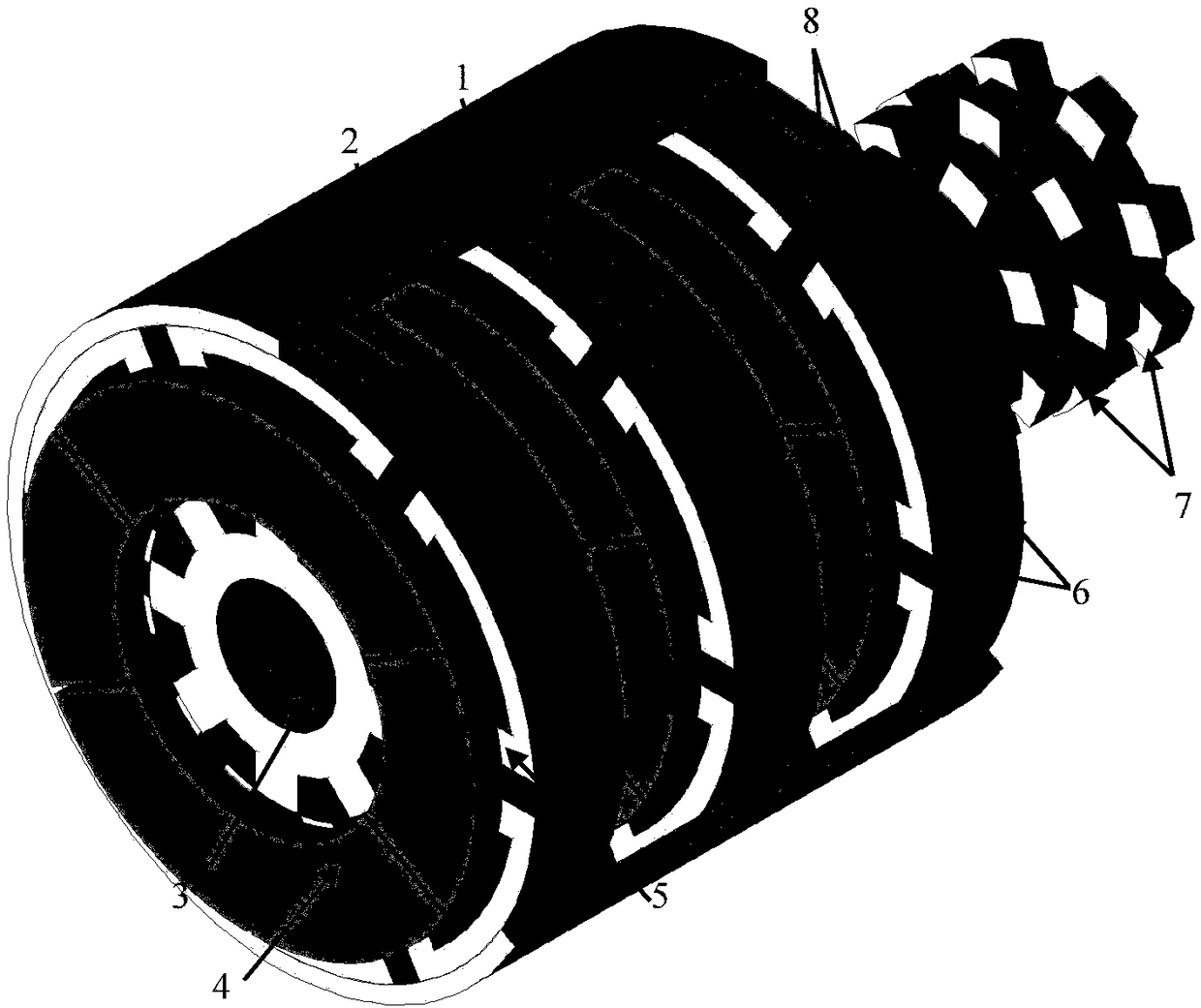

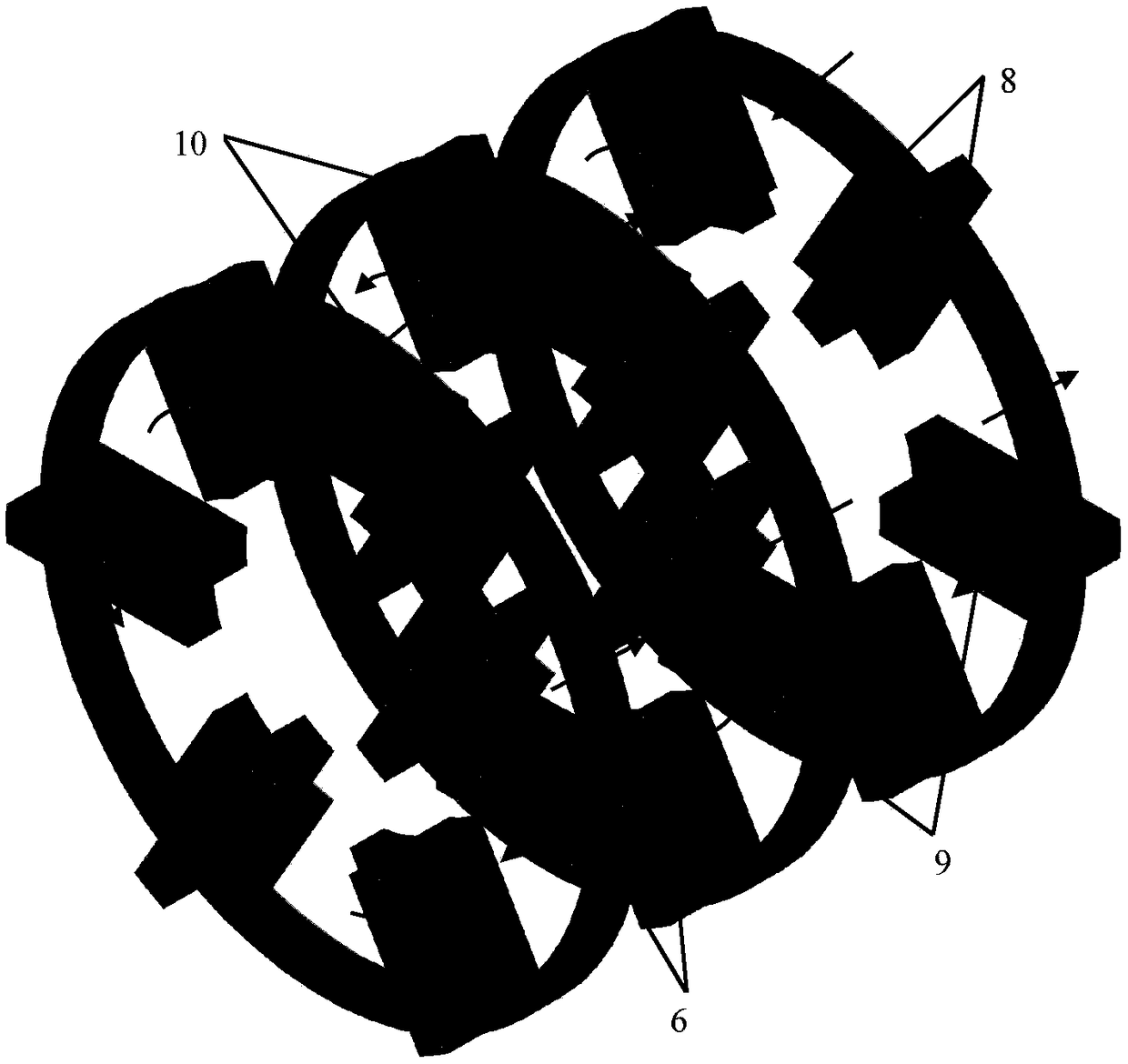

[0023] The magnetic flux switching type linear rotary permanent magnet actuator, such as figure 1 As shown, the actuator is composed of casing (1), stator, mover, winding and mover shaft, and the stator part is as follows figure 2 As shown, it consists of a stator yoke (2), a stator pole (5), a tangentially magnetized permanent magnet (6), an axially magnetized permanent magnet (8) and a concentrated winding (4). The arrangement of the permanent magnets of the actuator is as follows image 3 As shown, the tangentially magnetized permanent magnet (6) is embedded inside the stator pole, and the magnetization direction of the adjacent tangentially magnetized permanent magnet is opposite. The axially magnetized permanent magnet (8) adopts a U-shaped structure and is embedded in the stator pole In the interior of the stator yoke, the magnetization direction of the adjacent axial magnetization permanent magnets is opposite, and the tangential magnetization direction (9) is complem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com