Drawing method for producing cylinder-shaped components from quartz glass

一种石英玻璃、圆柱形的技术,应用在玻璃的成型、玻璃的成型、玻璃制造设备等方向,能够解决费力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

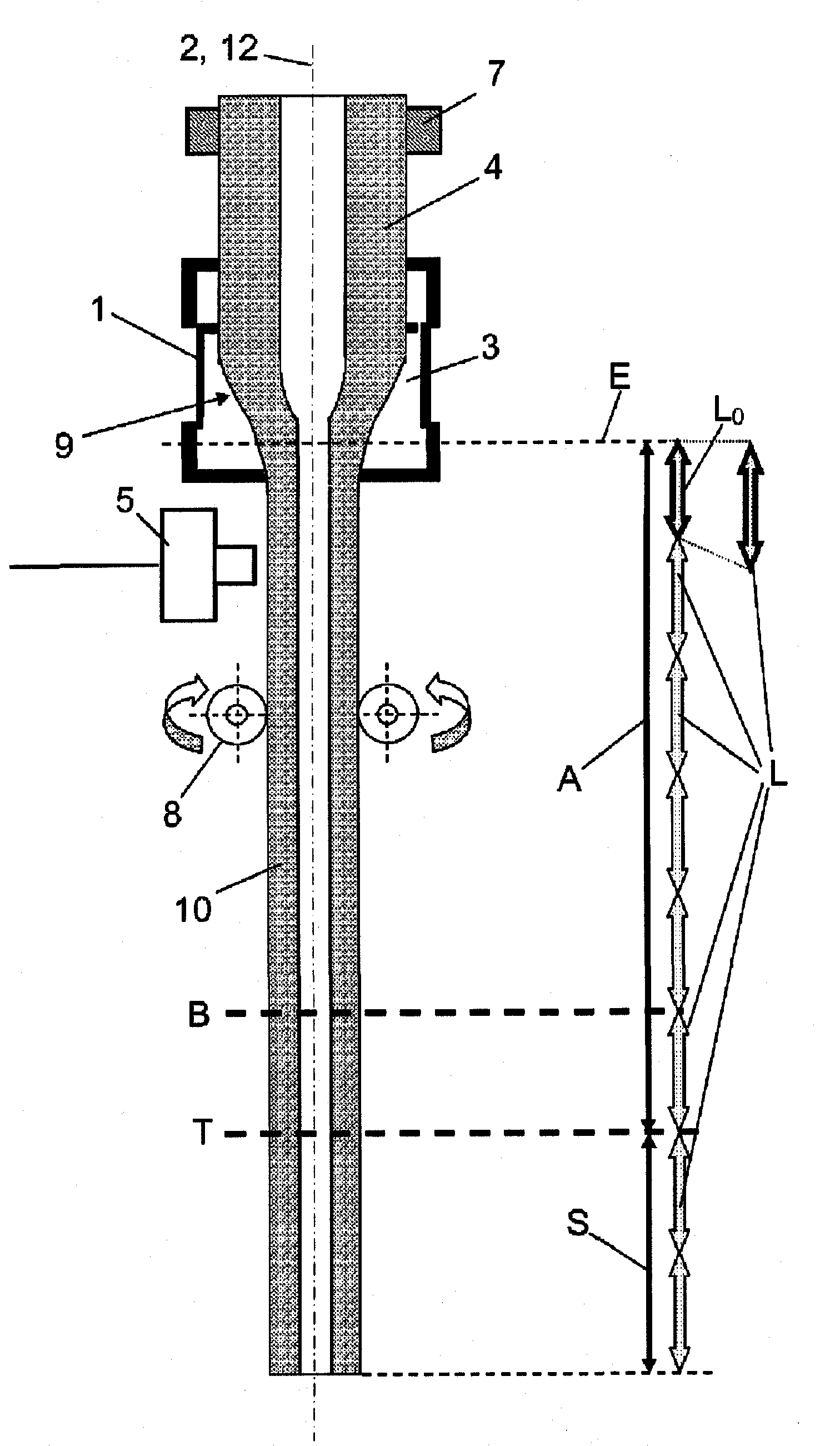

[0045] according to figure 1 The arrangement of FIG. 1 shows a resistance heater with a vertically oriented heating tube 1 . The heating tube 1 consists of an annular graphite element with an inner diameter of 193 mm, an outer diameter of 215 mm and which encloses a heating zone 3 with a length of 100 mm.

[0046] The heating tube 1 is supplied with a hollow cylinder 4 of quartz glass, which hollow cylinder has a longitudinal axis 12 oriented as parallel as possible to the drawing axis 2 . The upper end of the hollow cylinder 4 is connected to a holding device 7 by means of which it is displaceable in the horizontal direction (xy), vertically movable up and down and rotatable about the drawing axis 2 .

[0047] The hollow cylinder 4 is softened in the heating zone 3 and a tubular stream 10 is drawn vertically downward from the softened zone, with the formation of a drawing bulb. A roller drawer 8 is used as the drawer, the roll drawer comprising two drawer rolls facing each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com