Structure of standard steel forms for constructing thin-wall high pier groups with four sides being variable cross sections by form turnover

A technology of standard formwork and standard steel, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of large processing volume, complicated construction procedures, and poor appearance quality of high piers, and achieve reasonable structural design and good appearance quality , High construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

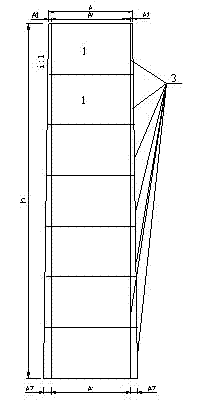

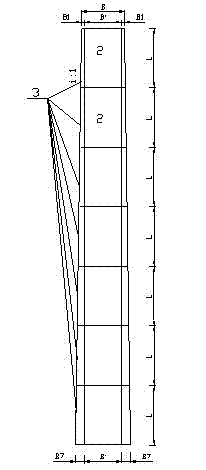

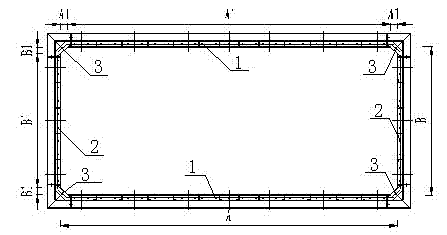

[0029] Embodiment of the present invention: each section of standard steel formwork includes a standard formwork 1 for the horizontal bridge direction, a standard formwork 2 for the longitudinal bridge direction, and a slope closing formwork 3, and the slope closing formwork 3 is arranged on the standard formwork 1 for the horizontal bridge direction and the standard formwork 2 for the longitudinal bridge direction At the corners between them, the heights of the horizontal bridge to the standard formwork 1, the longitudinal bridge to the standard formwork 2, and the closing slope formwork 3 are the same and equal to the height L of the single construction section, and the modular section of the closing slope formwork 3 = group height h÷ single construction Section height L, slope rate of closing slope template 3 = pier body slope rate = slope rate i of high pier group, top width An and Bn of each section closing slope formwork according to height L of single construction section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com