Connection structure of well base and pitshaft of inspection well

A technology for connecting structures and inspection wells, which is applied to underwater structures, infrastructure engineering, drainage structures, etc., can solve problems such as inconvenience in carrying, and achieve the effect of convenient carrying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

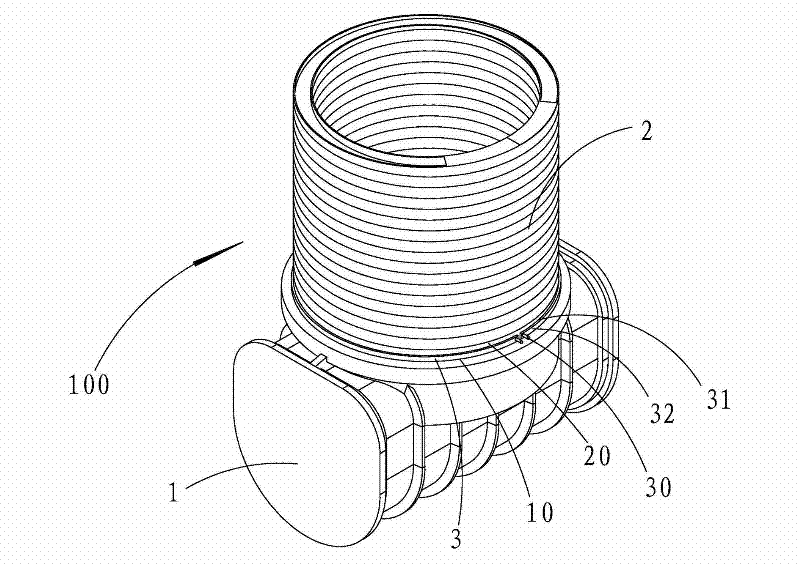

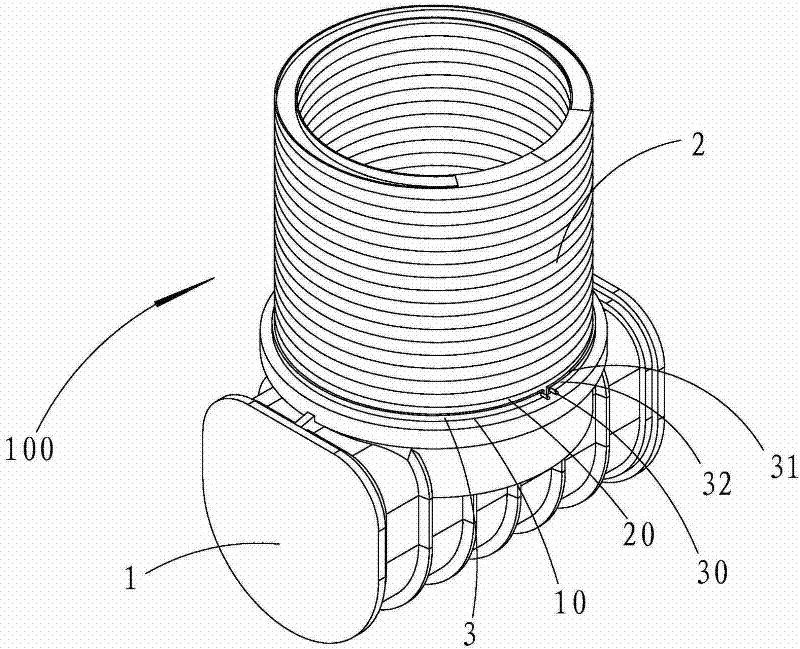

[0010] see figure 1 , a connection structure 100 between the well base and the shaft of an inspection well, which includes: the well base 1, the shaft 2, and the electric fusion part 3 arranged at the connection between the well base 1 and the shaft 2, and the electric fusion part 3 includes: Wire, the plastic coated on the outside of the electric fuse and the terminal 30 connected with the electric fuse, the top of the well base 1 is provided with an opening that matches the shaft 2, and the inner surface of the electric fuse 3 31 is in contact with the outer surface 20 of the wellbore 2, and the outer surface 32 of the electrofusion element 3 is in contact with the hole wall 10 of the well base opening. The two ends of the inspection well base 1 are sealed. The advantage of this design is that the construction is more flexible. On the construction site, openings matching it can be provided on the seal according to the specific size of the connecting pipeline.

[0011] The p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap