Disassembly method for touch panel with assembly shell

A touch panel and assembling shell technology, which is applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method of the present invention will be further described below by taking a mobile phone as an example in conjunction with the accompanying drawings.

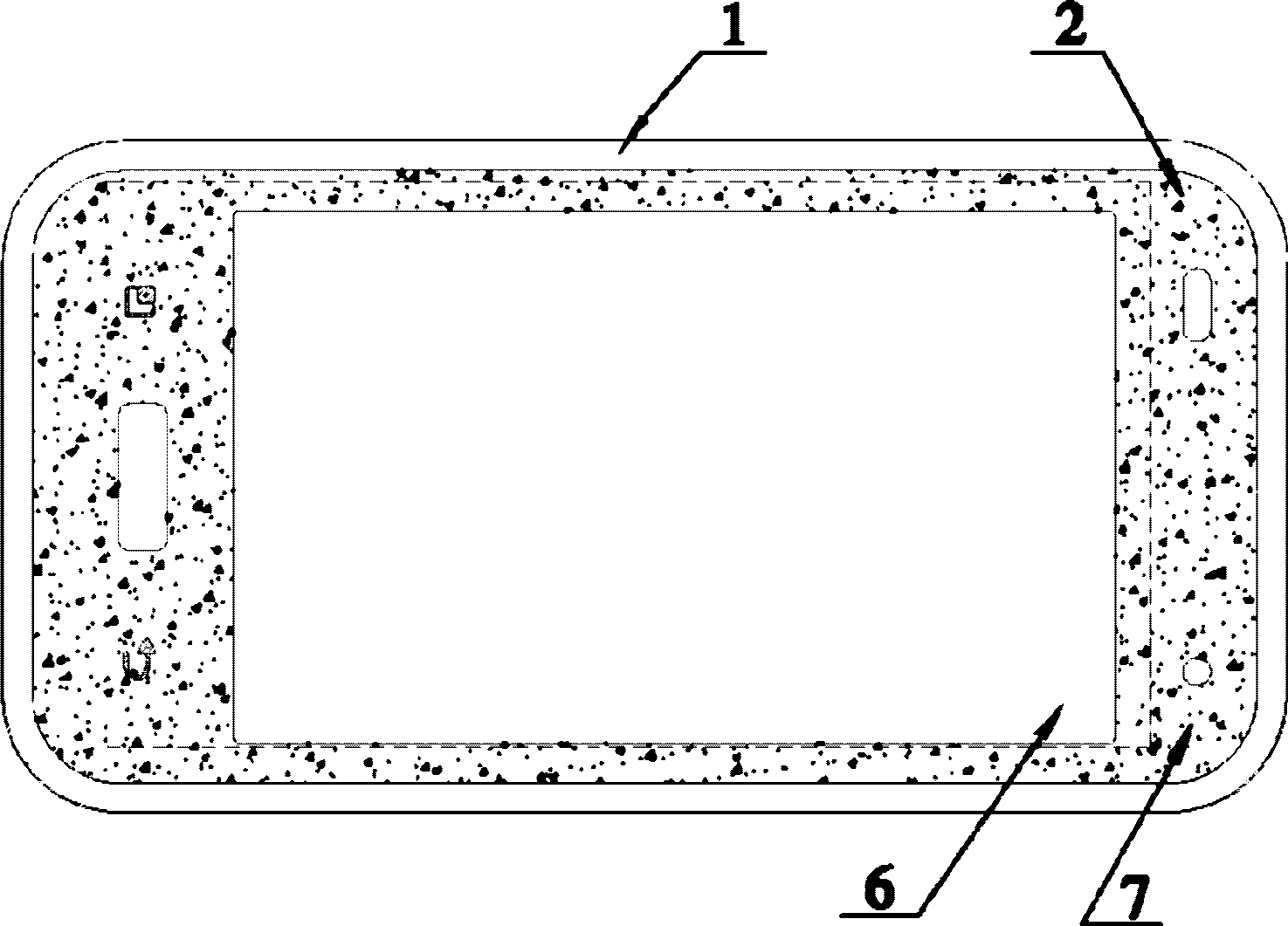

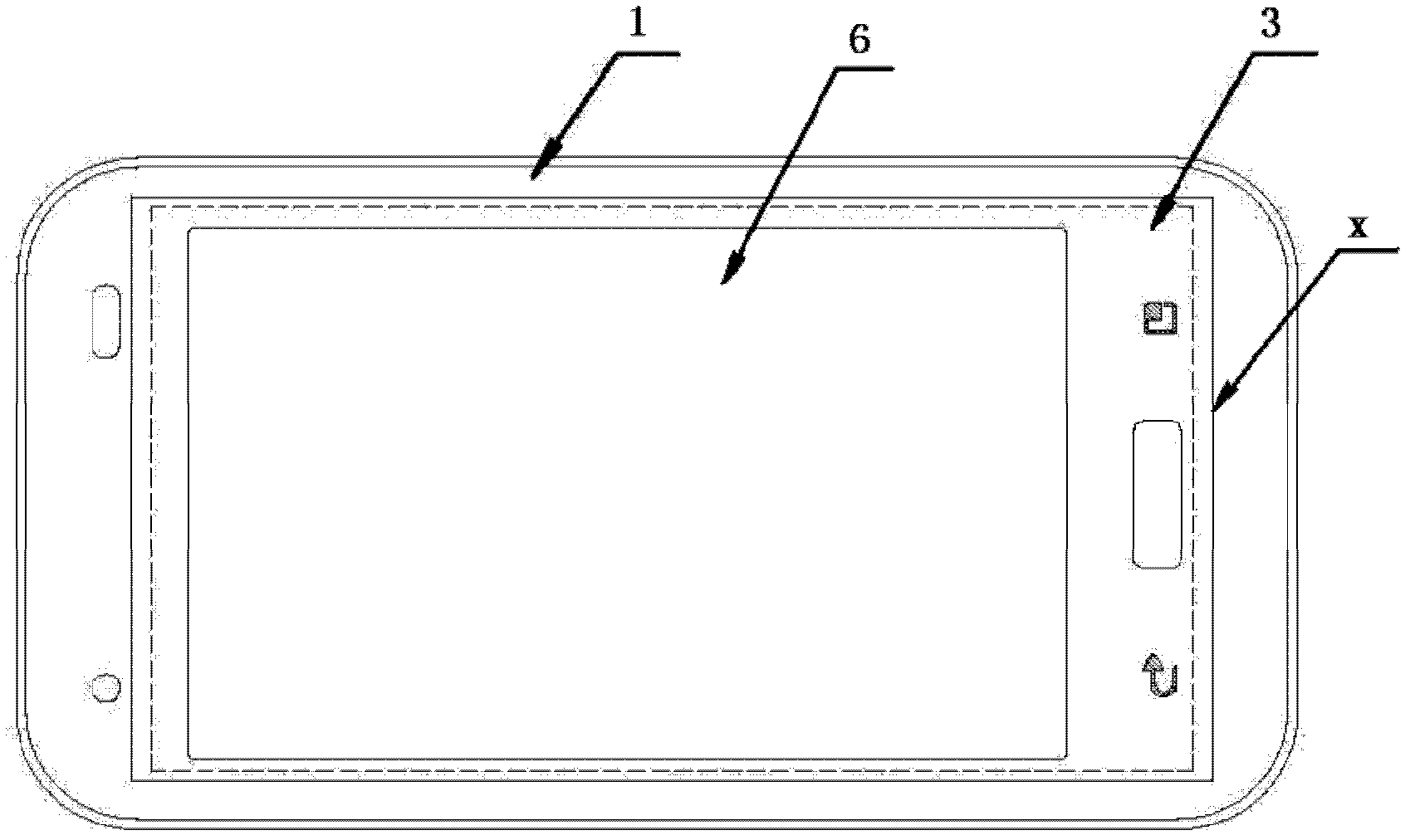

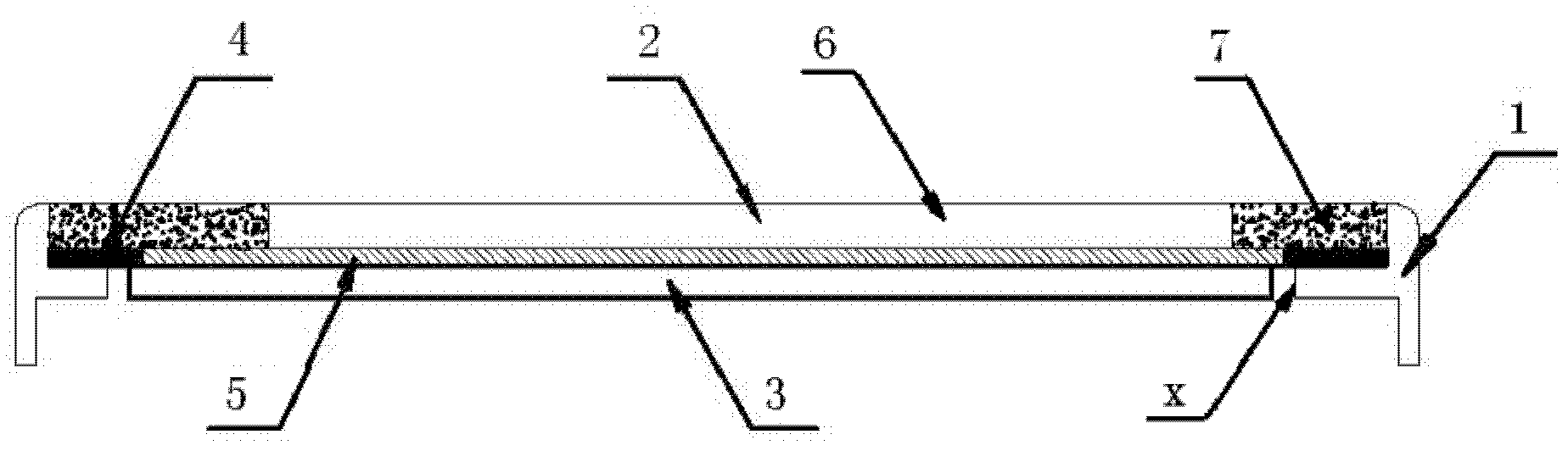

[0022] figure 1 is the front view of the touch panel with assembled shell of the present invention, figure 2 is the rear view of the touch panel with the assembled housing, image 3 for figure 1 A-A in the sectional view. see image 3 , the touch panel 10 includes a frame 1 , a cover lens 2 , a sensor layer 3 , a first adhesive layer 4 and a second adhesive layer 5 . The first adhesive layer 4 is used for laminating the housing 1 and the protective panel 2 , and the protective panel 2 and the sensor layer 3 are pasted and joined by the second adhesive layer 5 . The shell 1 can be magnesium aluminum alloy or hard plastic. The protection panel 2 is generally made of tempered glass, has an active area 6 and a black matrix 7 , and extends out of the inner frame line X of the housing 1 , as shown in FIG. 3 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com