Pin contact and electric connector using pin contact

A technology of pin contacts and electrical connectors, which is applied to contact parts and other directions, can solve problems such as unreliable contact, and achieve the effects of solving unreliable contact, increasing contact area, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

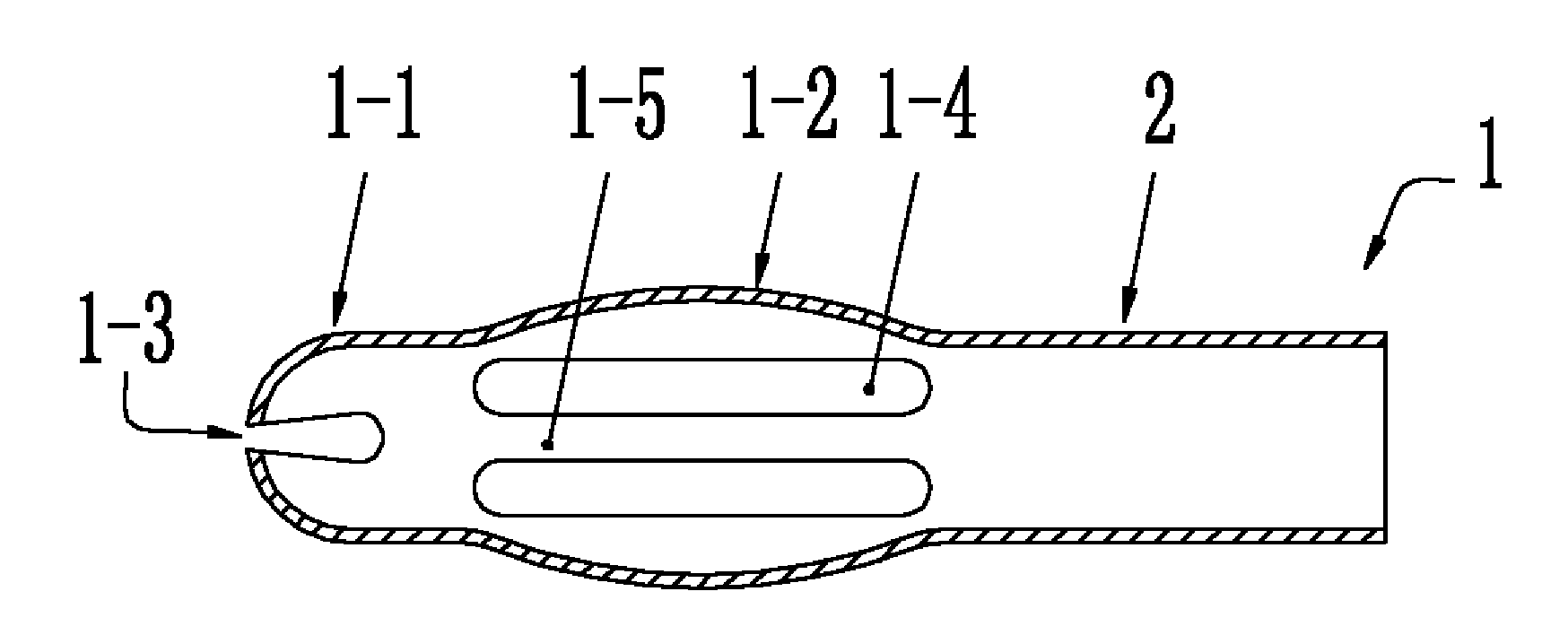

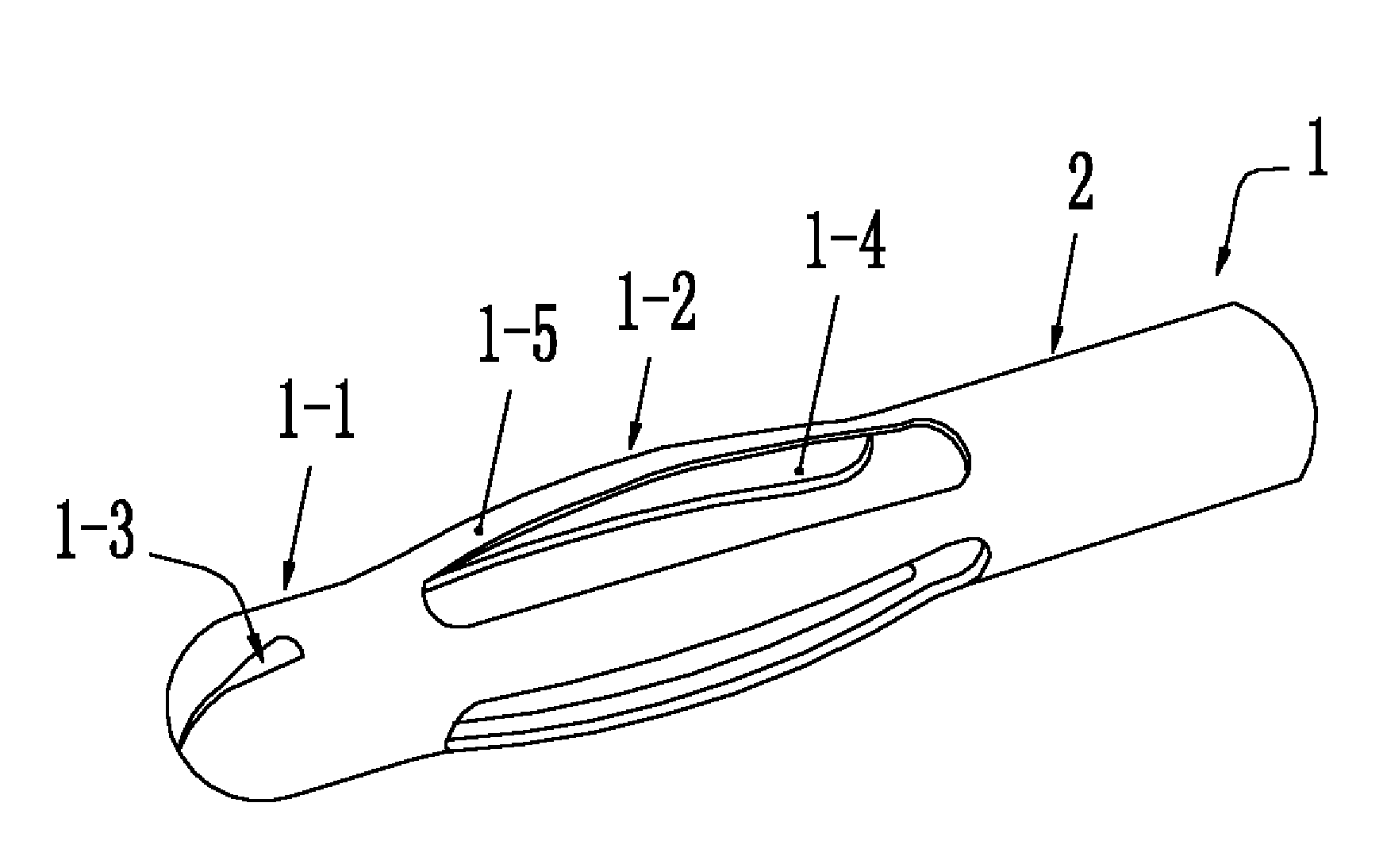

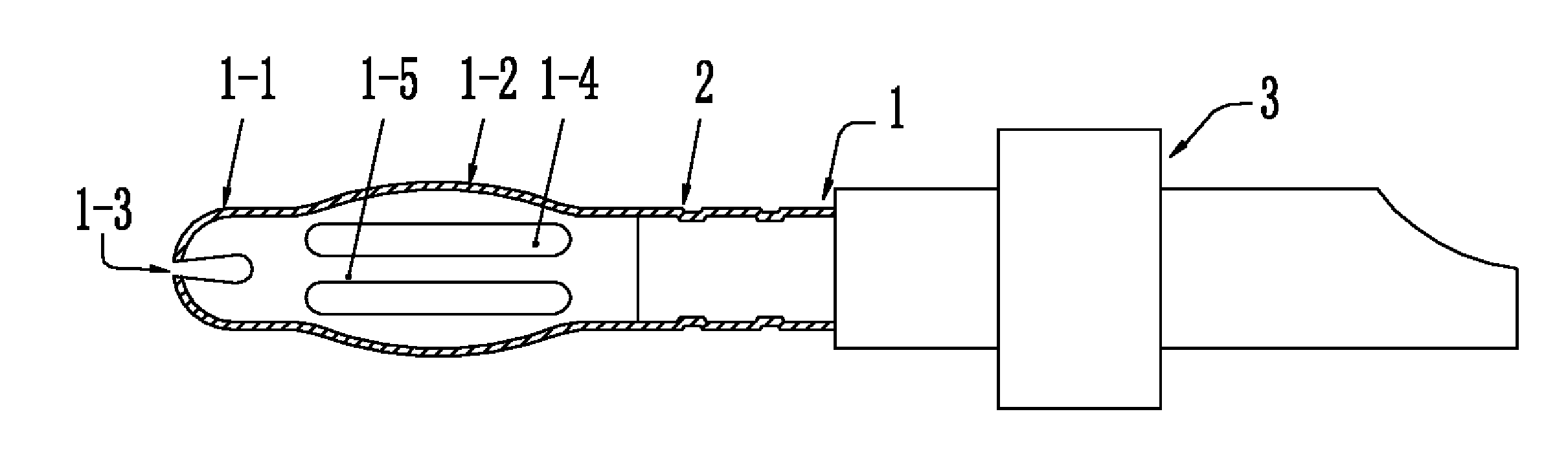

[0019] Embodiment 1 of pin contacts, such as Figure 1-2 As shown, there is a tubular contact base 1, the contact base 1 adopts a copper tube, the contact base 1 has a guide section 1-1 at the front end and a contact section 1-2 at the rear end, the guide section 1-1 and the contact section 1-2 are coaxially arranged, and the end of the contact section 1-2 away from the leading section is coaxially provided with a tail section 2, which is tubular in shape. In this embodiment, the tail section 2 is a part of the contact element base 1, and the tail section 2 It is used to cooperate with the insulator of the corresponding connector to fix the pin contact, and the end surface (of the tube wall) of the front end (the end away from the contact section) of the guide section 1-1 is provided with two along the contact base The notch 1-3 with the axis of 1 recessed backwards, so that the front end of the guide section 1-1 can be folded into the contact base 1 and form an arc surface, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com