Pressure sensor

A pressure sensor and pressure technology, applied in the direction of pressure sensor, sensor, measuring fluid pressure, etc., can solve the problems of large diameter, unable to meet medical needs, no dead zone, and unsatisfactory, and achieve the effect of reducing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

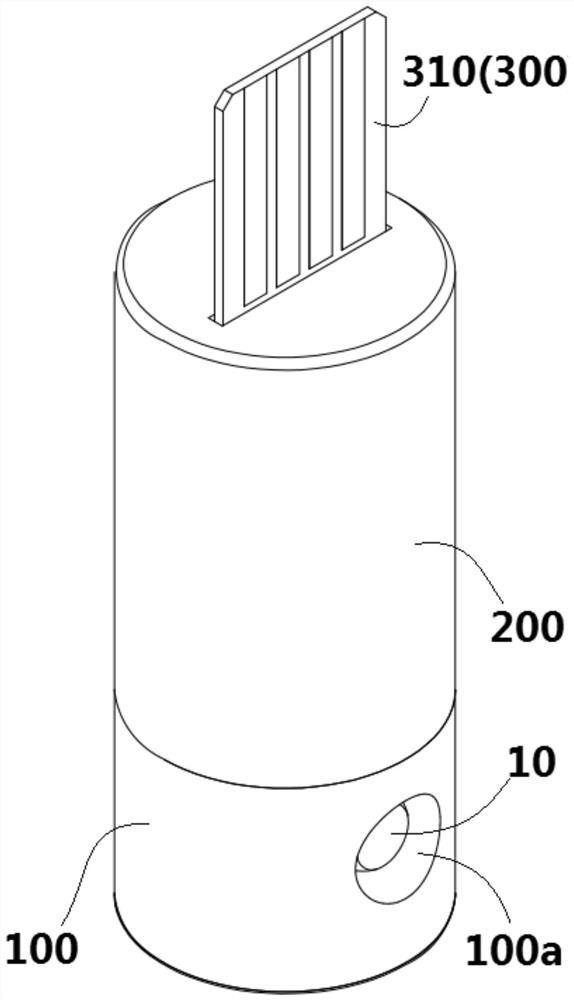

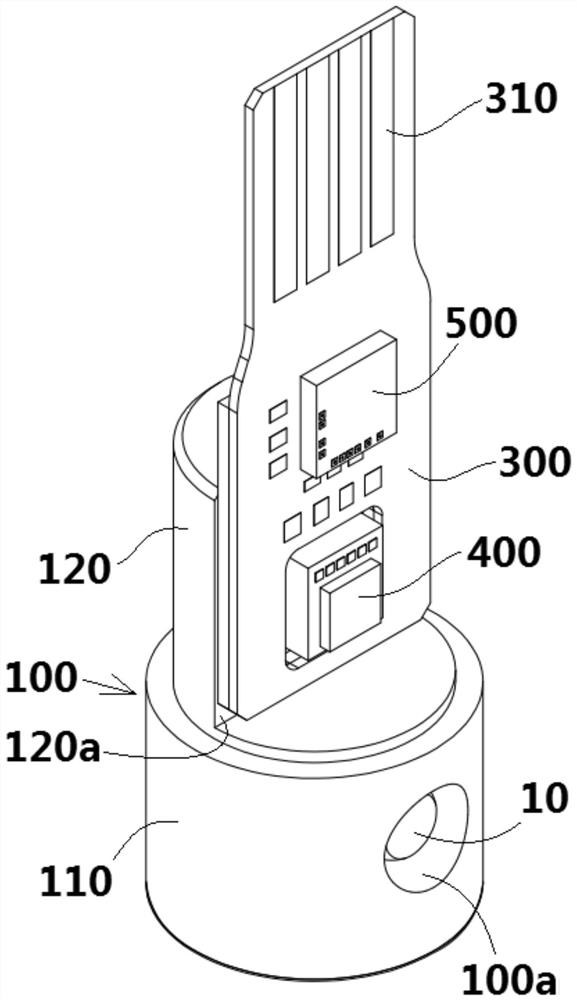

[0043] Figure 1 to Figure 4 A pressure sensor according to a first embodiment of the invention is shown. in, figure 1 A three-dimensional schematic diagram showing a pressure sensor according to the first embodiment of the present invention; figure 2 show figure 1The pressure sensor shown with the housing 200 removed; image 3 show figure 2 A three-dimensional schematic view of the pressure sensor shown when viewed from the rear; Figure 4 show figure 1 Cutaway view of the pressure sensor shown.

[0044] Such as Figure 1 to Figure 4 , in the illustrated embodiment, the pressure sensor mainly includes: a body 100 , a diaphragm 600 , a pressure detection chip 400 and a circuit board 300 . A housing chamber for housing liquid is formed inside the body 100 . The diaphragm 600 is attached to the body 100 and is adapted to transmit the pressure of the external medium to the liquid in the chamber. The pressure detection chip 400 is mounted on the body 100 for detecting ...

no. 2 example

[0069] Figure 5 and Figure 6 A pressure sensor according to a second embodiment of the invention is shown. in, Figure 5 A schematic perspective view showing a pressure sensor according to a second embodiment of the present invention, wherein the housing 200 is removed; Figure 6 A cross-sectional view of a pressure sensor according to a second embodiment of the present invention is shown.

[0070] Figure 5 and Figure 6 The second embodiment shown with Figure 1 to Figure 4 The main difference of the first shown embodiment is the location of the liquid filling port 110a and the positioning groove.

[0071] Such as Figure 5 and Figure 6 As shown, in the illustrated embodiment, the liquid filling port 110 a is formed on the top surface of the installation part 120 and directly communicates with the upper end of the trunk passage 101 .

[0072] Such as Figure 5 and Figure 6 As shown, in the illustrated embodiment, a circular positioning groove 100b and a bar-sh...

no. 3 example

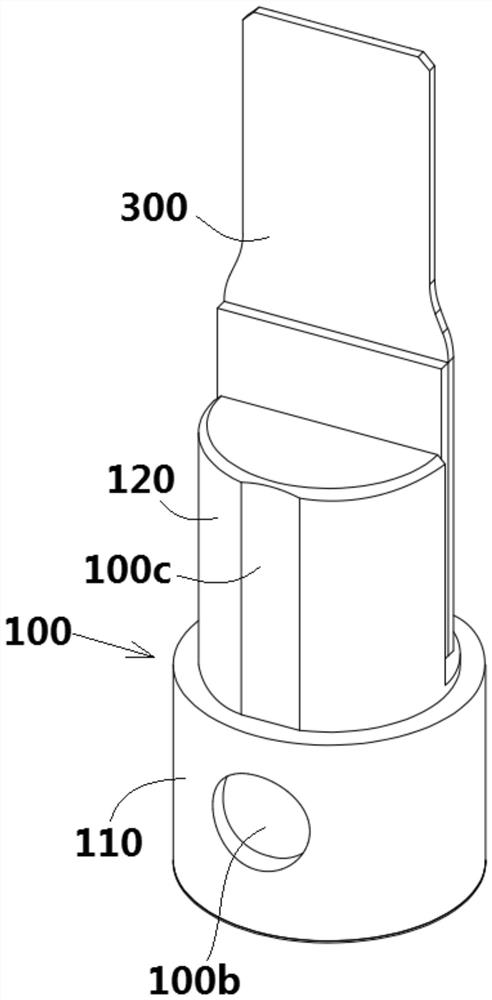

[0075] Figure 7 and Figure 8 A pressure sensor according to a third embodiment of the invention is shown. in, Figure 7 A schematic perspective view showing a pressure sensor according to a third embodiment of the present invention, wherein the housing 200 is removed; Figure 8 A sectional view showing a pressure sensor according to a third embodiment of the present invention;

[0076] Figure 7 and Figure 8 The third embodiment shown with Figure 1 to Figure 4 The main difference of the first shown embodiment is the location of the liquid filling port 110a and the positioning groove.

[0077] Such as Figure 7 and Figure 8 As shown, in the illustrated embodiment, the liquid filling port 110a is formed on the peripheral surface of the installation part 120 on the side opposite to the installation surface 120a.

[0078] Such as Figure 7 and Figure 8 As shown, in the illustrated embodiment, a bar-shaped positioning groove 100c extending in the axial direction th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com