Vertical shaft-type double-turbine mixer

A technology of turbine stirring and twin turbines, which is applied to mixers with rotating stirring devices, mixers, water/sludge/sewage treatment, etc., which can solve the problems of easy impeller hanging impurities, reducer maintenance difficulties, and sludge lumps. Breaking and other problems, to achieve the effect of facilitating metabolism, improving oxygen transfer efficiency, and protecting from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

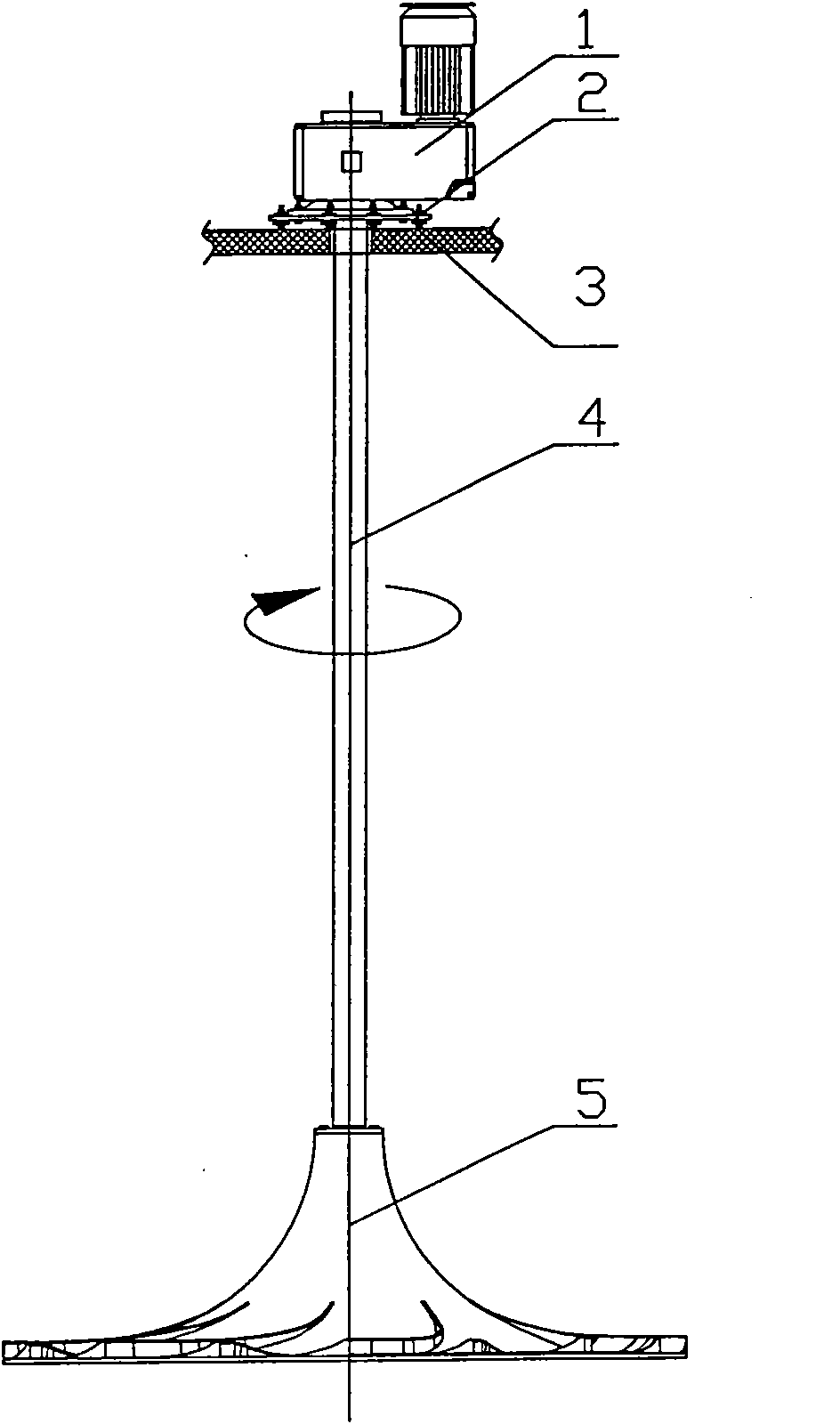

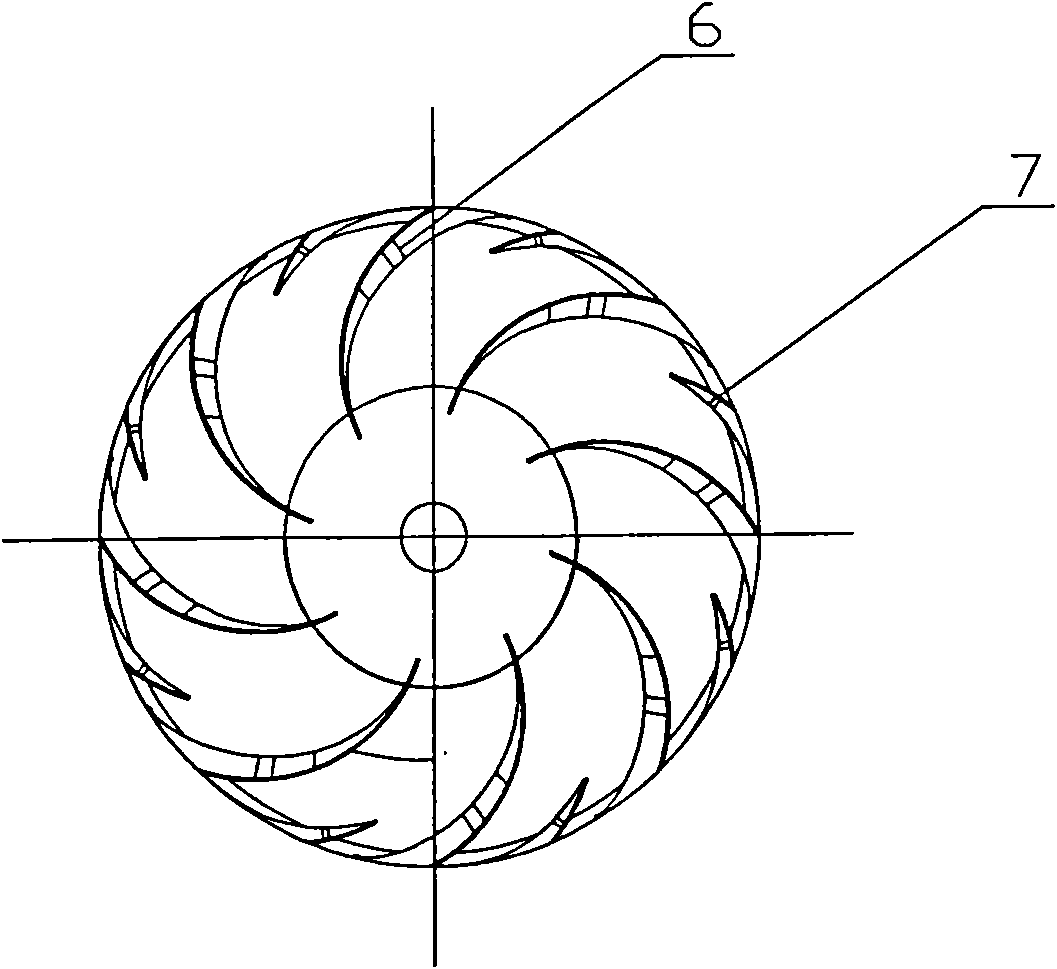

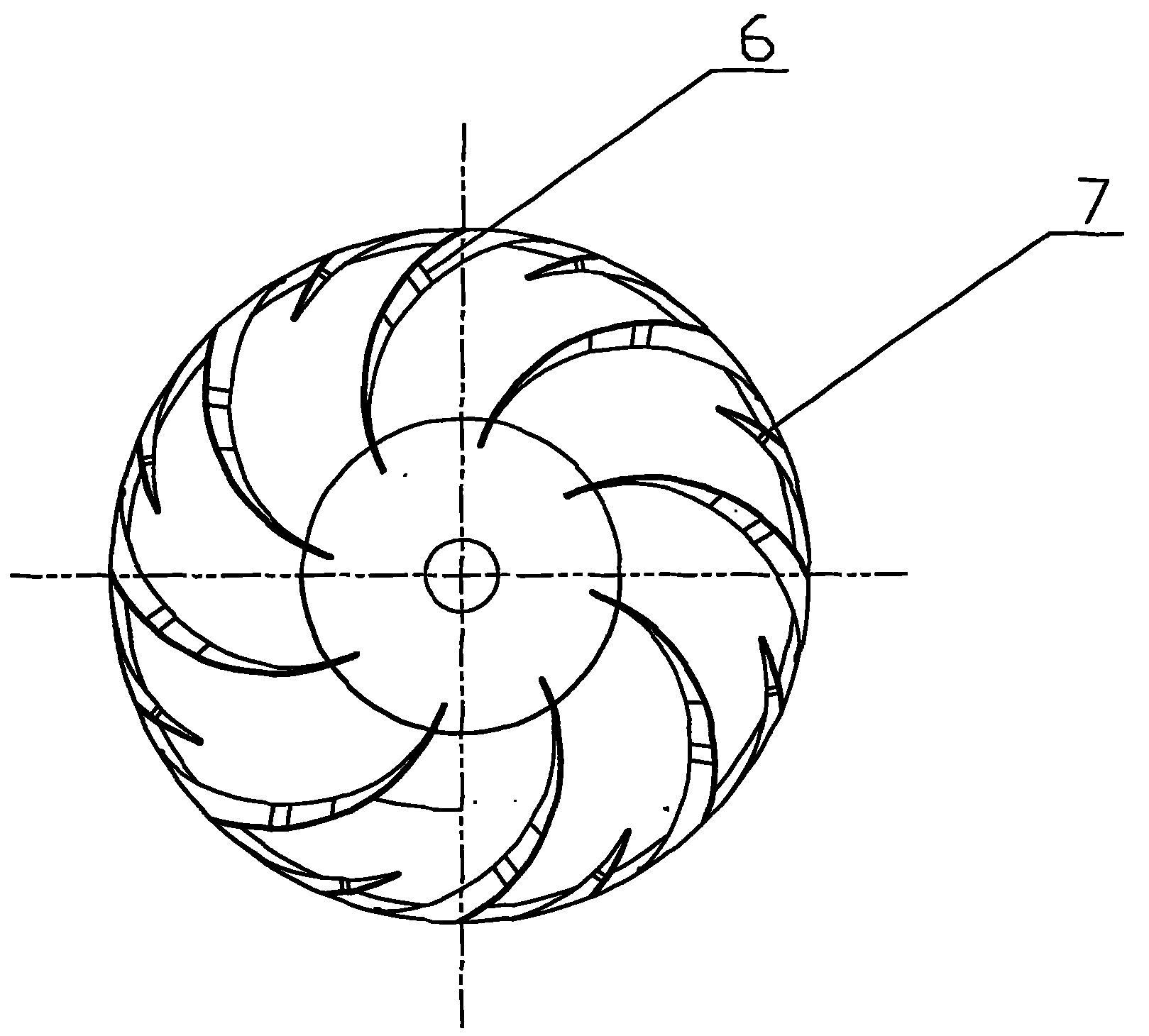

[0023] A vertical shaft double-turbine mixer, comprising a parallel gear reduction motor 1, an elastic fixed base 2, a hollow transmission shaft 4, and a turbine stirring impeller 5, the parallel gear reduction motor 1 is installed on the installation base 3 through the elastic fixed base 2, One end of the hollow transmission shaft 4 is connected to the parallel gear reduction motor 1, and the other end is connected to the turbine stirring impeller 5. The turbine stirring impeller 5 is in the shape of a concave cone, and long guide stirring ribs are distributed along the circumference on the inner side of the concave cone arc surface. 6 and short diversion stirring ribs 7; the long diversion stirring ribs 6 and the short diversion stirring ribs 7 are alternately distributed.

[0024] The long diversion stirring ribs 6 are distributed in a spiral involute shape along the concave conical arc surface of the turbine stirring impeller 5, and the intersection points of the extended l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com