Mechanical shock-absorption type driver seat assembly

A driver and mechanical technology, applied in the direction of the seat suspension device, etc., can solve the problems of reducing the space of the cab and the integrity of the seat appearance, etc., and achieve the effect of improving aesthetics, compact structure, and good acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

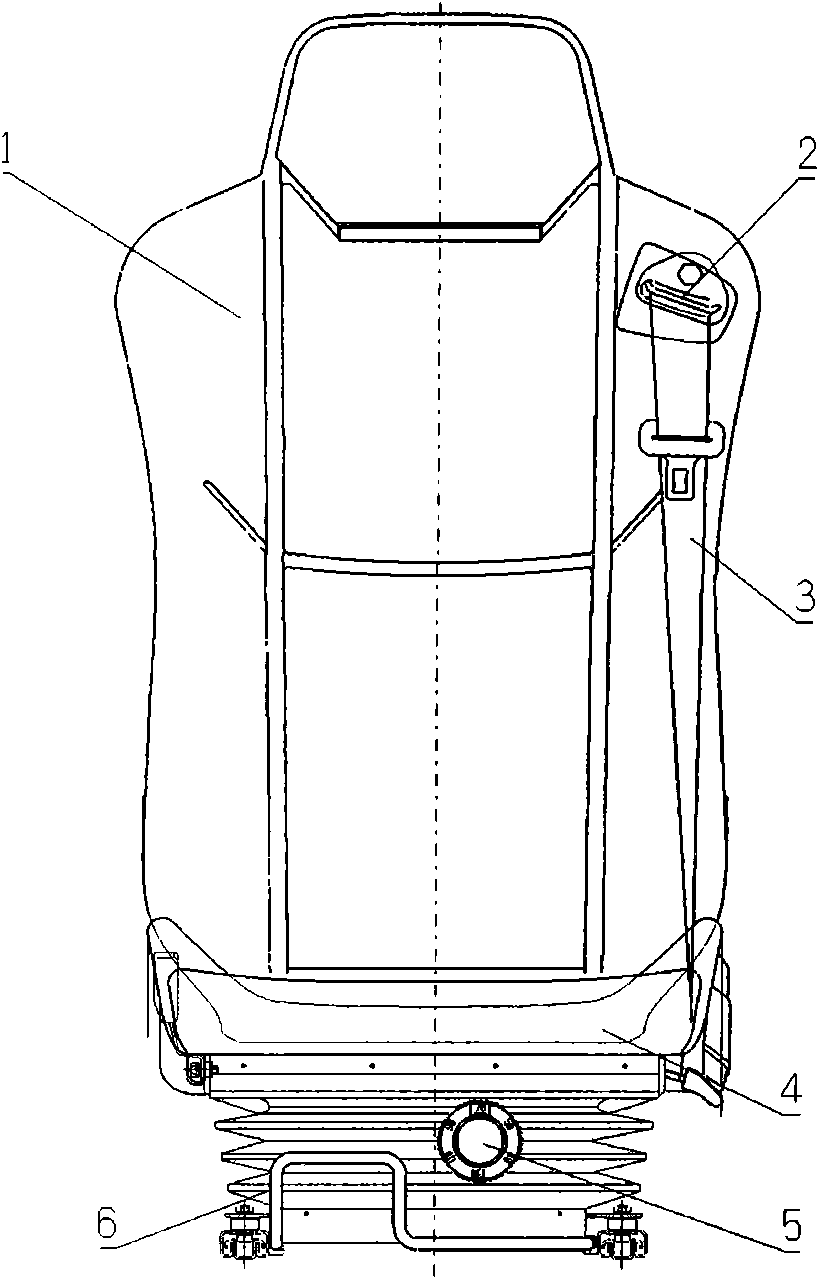

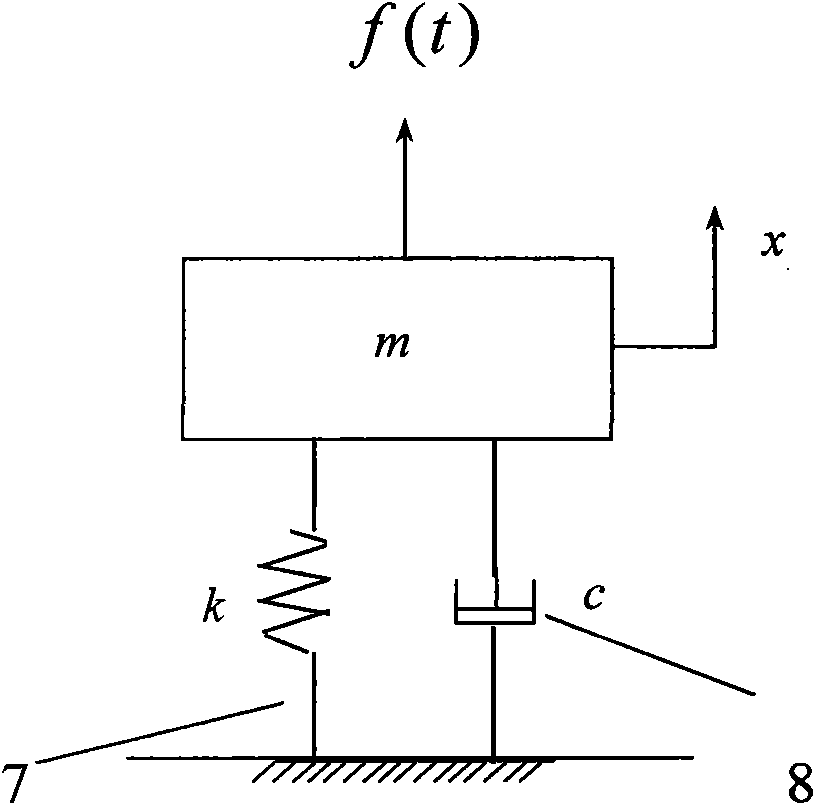

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 As shown, the mechanical vibration-absorbing driver's seat assembly is composed of a backrest 1, a fixed point on the safety belt 2, a safety belt 3, a seat cushion 4, a vibration-damping system 5 and an adjustment mechanism 6; it is characterized in that: the backrest 1 There is a hole for installing the fixed point 2 on the safety belt, and the safety belt 3 passes through the backrest 1; the vibration reduction system 5 and the adjustment mechanism 6 are fixed under the seat cushion 4, and the vibration reduction system 5 is composed of a coil spring 7 and a damper 8 made.

[0012] Such as figure 1 As shown, the height dimension of the backrest 1 of the driver's seat assembly and the width dimension of the shoulder rest part are relatively large, holes are opened at appropriate positions, and the safety belt 3 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com