Weighing sensing system based on deformation quantity detection of vehicle axle housing

A technology of weighing sensing and deformation, which is applied in the field of sensing systems, can solve the problems of difficult selection of sensing positions, influence of internal stress of sensing elements, and influence of service life of sensing elements, etc., to reduce the impact of unbalanced load, It is convenient for accurate measurement and the effect of convenient and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

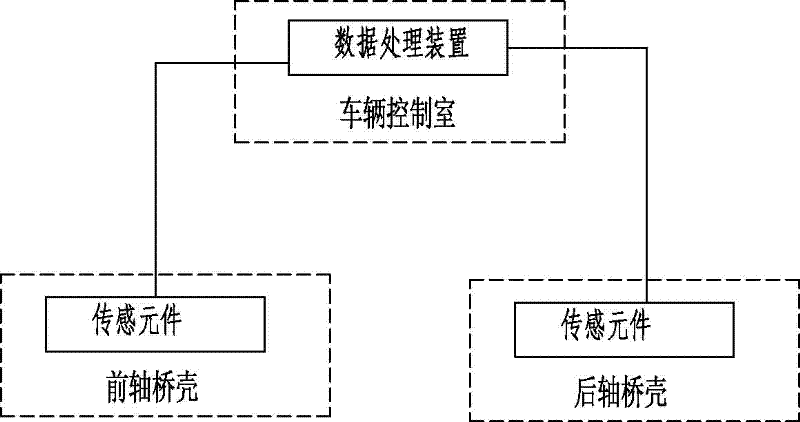

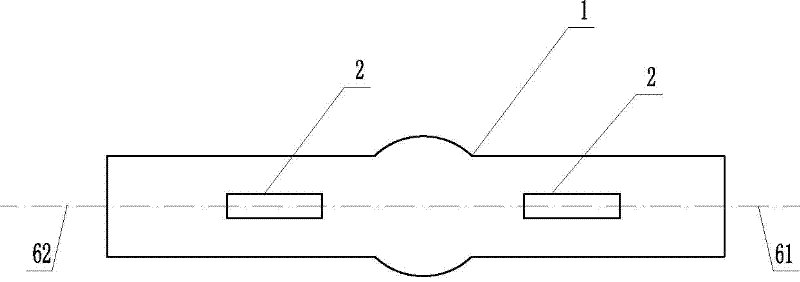

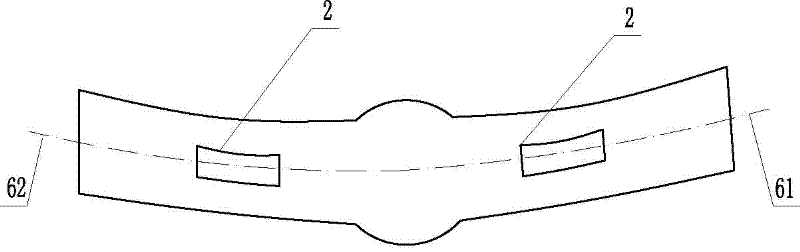

[0038] Such as Figure 1 to Figure 7 As shown, a weighing sensing system based on the deformation of a vehicle axle housing includes a sensing element and a data processing device;

[0039] It also includes an elastic body 9 carrying the sensing element, the sensing element is placed in the elastic body 9, and the elastic body 9 is provided at the position of the neutral surface 62 on the surface wall of the vehicle axle housing 1.

[0040] The axle housing 1 includes a front axle axle housing and a rear axle axle housing. Several elastic bodies 9 are symmetrically distributed on the left and right sides of the axle housing 1.

[0041] The sensor processing device is arranged in the vehicle control room, and the data processing device and the sensor element are connected through corresponding wires. The weighing sensor system based on the deformation of the vehicle axle housing also includes a corresponding wire Conduit 7, and the elastic body 9 is also provided with a through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com