A kind of high-viscosity polyvinyl acetate emulsion and preparation method thereof

A technology of polyvinyl acetate emulsion and vinyl acetate monomer, which is applied in the field of polyvinyl acetate emulsion and its preparation, can solve problems that are difficult to eliminate, affect the appearance of latex white glue, affect the environmental protection and performance of latex white glue, and achieve easy operation, Easy to industrialized production, the effect of low conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

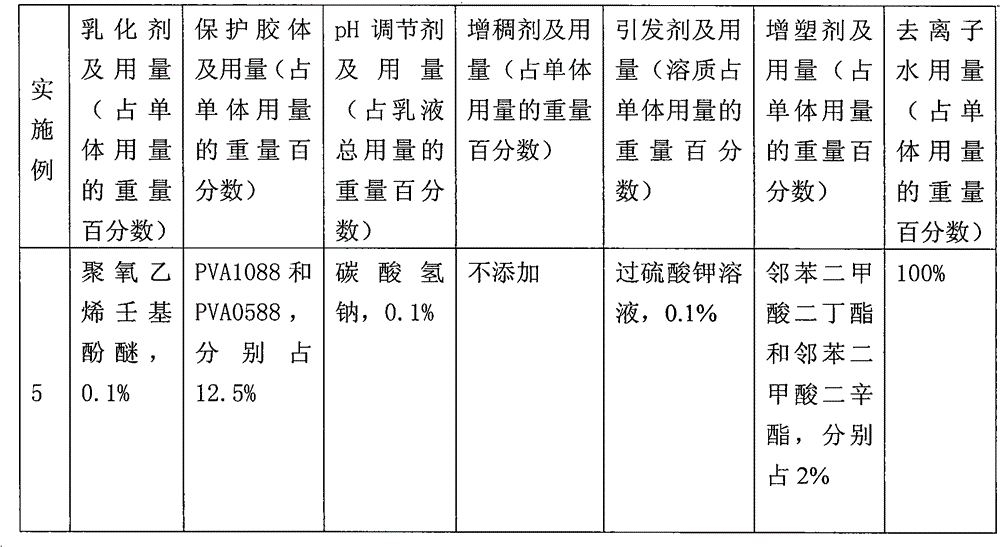

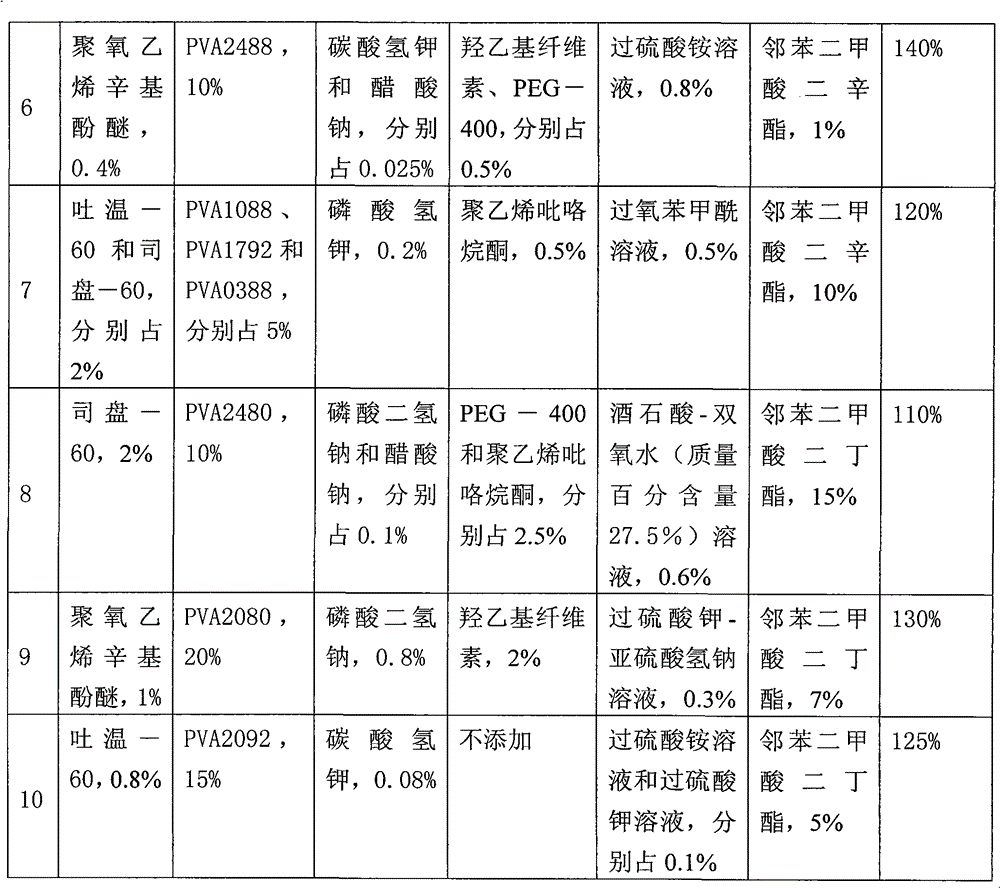

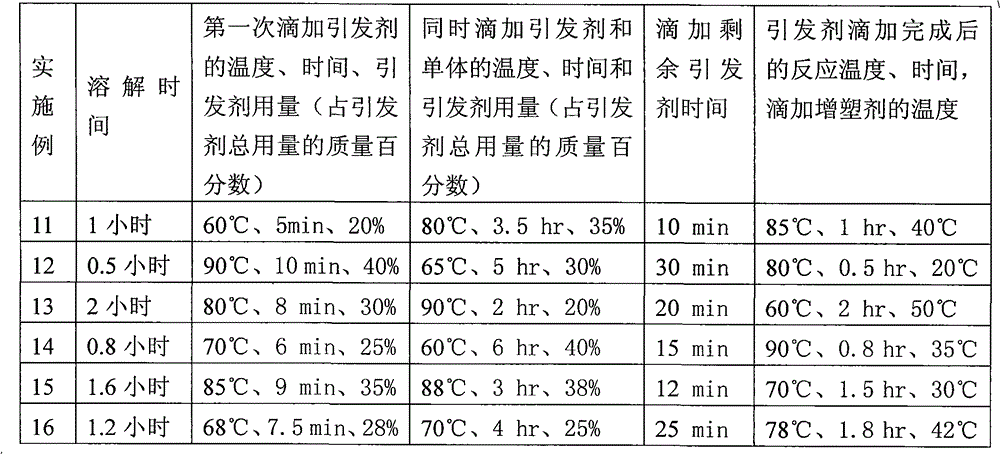

Examples

Embodiment 1

[0026] A kind of preparation method of high viscosity polyvinyl acetate emulsion is as follows:

[0027] Add 428.0g deionized water into the four-neck flask, add 25.0g PVA1788, 50.0g PVA1792, 2.1g emulsifier X-100, 1.0g sodium bicarbonate, 2.0g polyethylene glycol 400 (PEG-400) under stirring , heated up to 80°C. The initiator was prepared with 65.0 g deionized water and 1.3 g potassium persulfate. After dissolving for 1 hour, add 25.0 g of initiator to the reaction bottle, drop 420.0 g of vinyl acetate monomer and initiator, and react for about 4 hours. Add the remaining 10.0 g of initiator within 15 minutes, then keep the temperature at 85°C for 1 hour, lower the temperature, wait until the temperature drops to 40°C, add 40.0g of dibutyl phthalate, stir evenly, and discharge. The viscosity of the synthesized polyvinyl acetate emulsion measured at 25°C (LVGT viscometer 4# rotor 1.5rpm) was 280000mpa·s.

Embodiment 2

[0029] A kind of preparation method of high viscosity polyvinyl acetate emulsion is as follows:

[0030] The reaction raw materials are: 426.8g deionized water, 40.0g PVA2488, 10.0g polyvinylpyrrolidone, 2.1g emulsifier X-100, 1.0g sodium bicarbonate, 65.0g deionized water and 1.3g potassium persulfate to prepare the initiator, acetic acid Vinyl ester monomer 420.0g, dioctyl phthalate 42.0g. The reaction process is the same as in Example 1, and the viscosity of the synthesized polyvinyl acetate emulsion is 220000mpa·s.

Embodiment 3

[0032] A kind of preparation method of high viscosity polyvinyl acetate emulsion is as follows:

[0033] The reaction raw materials are: 427.0g deionized water, 25.0g PVA2488, 25.0g PVA1788, 3.0g Tween-60, 1.7g Span-60, 1.0g sodium bicarbonate, 40.0g deionized water and 1.0g sodium tartrate, 40.0 g deionized water and 3.0 g hydrogen peroxide (the mass concentration of hydrogen peroxide is 27.5%) are prepared as a redox initiator, 420.0 g of vinyl acetate monomer, and 22.0 g of dibutyl phthalate. The reaction process is the same as in Example 1, and the viscosity of the synthesized polyvinyl acetate emulsion is 250000mpa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com