Preparation method for ceramic casting mold for single-crystal high-temperature alloy parts

A ceramic casting mold and superalloy technology, applied in the field of additive manufacturing, can solve the problems of easy hydration, difficulty in preparing calcium oxide water-based ceramic slurry, etc., and achieve the effects of weak interface reaction, shortening the preparation cycle, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, design the ceramic mold;

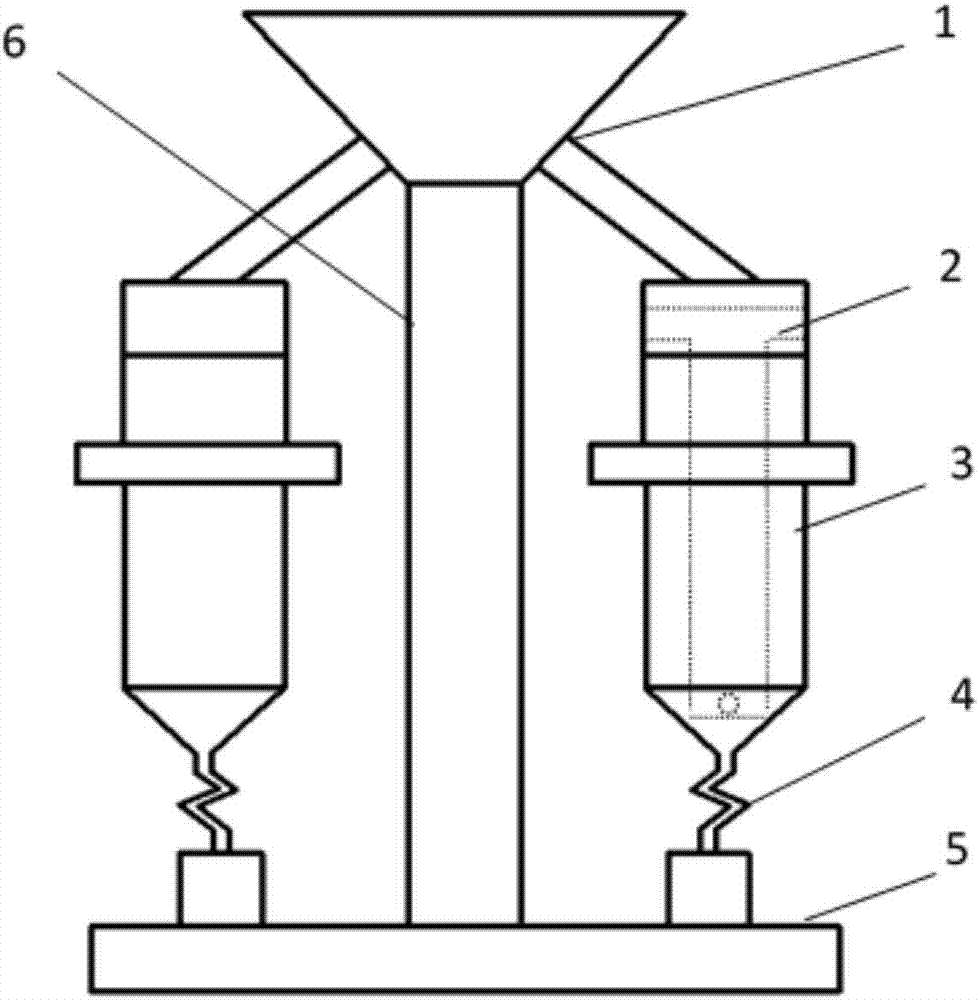

[0030] According to the requirements of the casting process, the casting mold is determined to be a module composed of two turbine blade parts, with the tip facing down, and a top pouring casting structure. The spiral crystal selector is used for crystal selection. The main parameters of the spiral crystal selector are: the height of the seeding section 30mm, seeding section diameter 17mm, spiral channel diameter 5mm, helix angle 20°, screw diameter 14mm, initial mold wall thickness 7mm; use UG 3D modeling software to model ceramic molds for parts; use Procast The casting simulation software simulates and analyzes the stress, temperature field, and crystal growth of the ceramic mold under the conditions of 1550°C pouring temperature, 1550°C mold temperature, and 3-5mm / min drawing rate, and iterates the design of the ceramic mold according to the simulation results; Under the condition that the strength of the mold is satisfied, the met...

Embodiment 2

[0042] Step 1: Determine the basic parameters of the overall structure, gating system, crystal selection system, and mold wall thickness according to the requirements of the casting process; use 3D CAD modeling software to model the ceramic mold of the part; use Procast casting simulation software to calculate the pouring temperature, casting Under the conditions of molding temperature and drawing rate, the stress, temperature field and crystal growth of ceramic mold are simulated and analyzed, and the design iteration of ceramic mold is carried out according to the simulation results; finally, a ceramic mold structure with uniform directional solidification temperature field and less casting defects is obtained and design parameters, establish a three-dimensional model of the ceramic mold;

[0043] Step 2, uniformly mix the photosensitive resin and dispersant by mechanical stirring, gradually add ceramic powder and sintering aid during the stirring process, and finally use bal...

Embodiment 3

[0050] Step 1: Determine the basic parameters of the overall structure, gating system, crystal selection system, and mold wall thickness according to the requirements of the casting process; use 3D CAD modeling software to model the ceramic mold of the part; use Procast casting simulation software to calculate the pouring temperature, casting Under the conditions of molding temperature and drawing rate, the stress, temperature field and crystal growth of ceramic mold are simulated and analyzed, and the design iteration of ceramic mold is carried out according to the simulation results; finally, a ceramic mold structure with uniform directional solidification temperature field and less casting defects is obtained and design parameters, establish a three-dimensional model of the ceramic mold;

[0051] Step 2, uniformly mix the photosensitive resin and dispersant by mechanical stirring, gradually add ceramic powder and sintering aid during the stirring process, and finally use bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com