Ink-jet 3D printing material, ink and preparation method thereof

A 3D printing and inkjet technology, applied in ink, additive processing, household appliances, etc., can solve the problems of easy agglomeration of binder powder, collapse of porous structure, inability to print large parts, etc., and achieve good fluidity and dispersion , a high degree of industrialization, and the effect of a good market foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] An aspect of the embodiments of the present invention provides a method for preparing an inkjet 3D printing material, which includes:

[0023] providing a homogeneous dispersion comprising particulate material, binder and solvent; and,

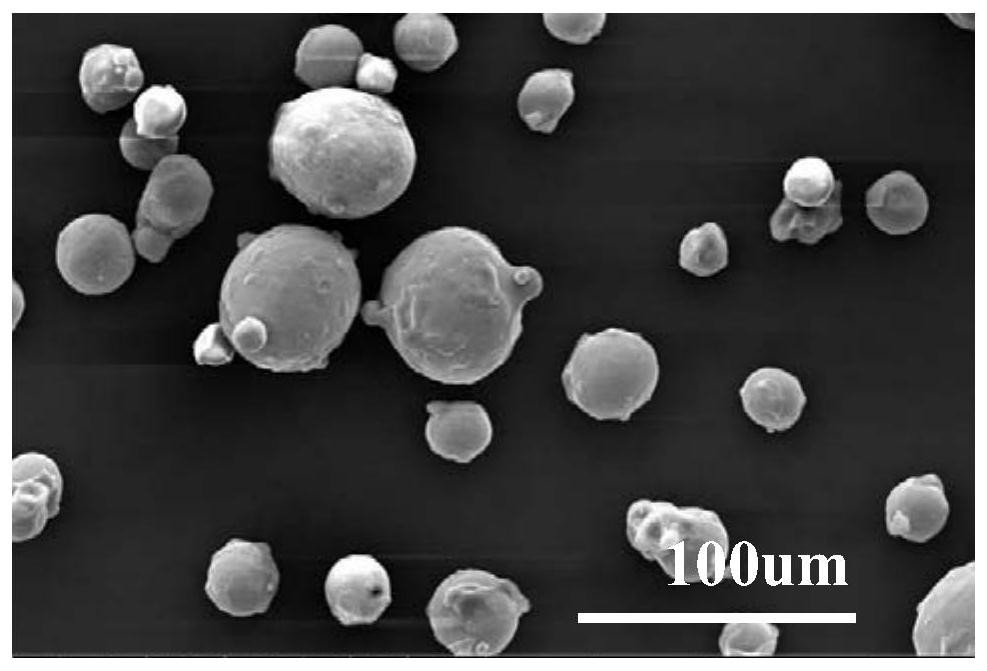

[0024] A binder precipitation agent is added to the uniform dispersion liquid, so that the binder in it is slowly precipitated and coated on the surface of the granular material, forming a coated granular material with a core-shell structure.

[0025] In some preferred embodiments, the preparation method includes: dissolving the binder in a solvent to form a binder solution, and then uniformly dispersing the granular material in the binder solution to form the uniform dispersion liquid.

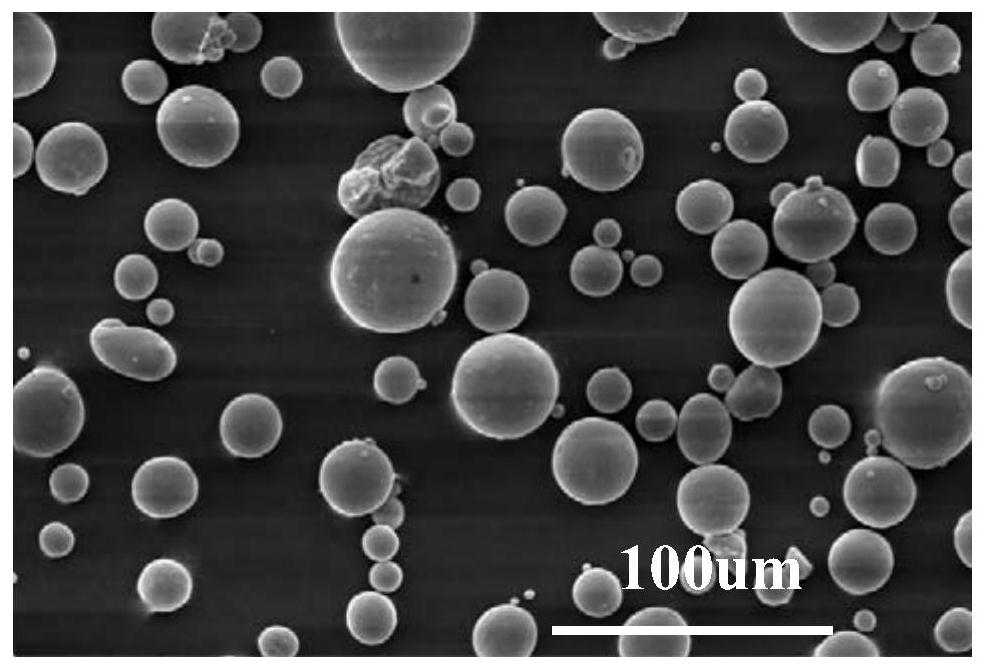

[0026] In some preferred embodiments, the granular material is required to be a powder with a mesh size of 100 or more, and the powder is a spherical or nearly spherical powder prepared by gas atomization or other processes. The present invention has...

Embodiment 1

[0057] (1) Take 20g of water-soluble starch and 500mL of water, pour into the reactor and stir evenly until completely dissolved;

[0058] (2) Take 1000g of 316L stainless steel powder (022Cr 17 Ni 12 Mo 2 ), the powder is aerosolized spherical powder. Add the stainless steel powder into the water-soluble starch solution, and stir quickly to make the stainless steel powder evenly disperse up and down in the solution;

[0059] (3) Slowly add 1000mL of ethanol into the stirring dispersion, and it can be observed that white water-soluble starch precipitates and is quickly wrapped on the stainless steel powder. With the gradual addition of ethanol, it can be observed that the stainless steel powder with a certain viscous coating adheres to each other Precipitated in gel form. Gradually reduce the stirring speed, pour out the mixed solution of the solvent and the precipitation agent in the reaction kettle, and the poured out solution can be distilled under reduced pressure to r...

Embodiment 2

[0065] (1) Take 24g of polyethylene glycol-8000 (PEG-8000) and 500ml of water, pour into the reactor and stir evenly until completely dissolved;

[0066] (2) Take 80 g of polyurethane (TPU) powder with a particle size distribution of 50 μm˜100 μm. Add the polyurethane powder into the PEG-8000 aqueous solution, and stir quickly to make the polyurethane powder evenly disperse up and down in the solution;

[0067] (3) Slowly add 1000mL of ethanol to the stirring dispersion, and it can be observed that white PEG-8000 precipitates and is quickly wrapped on the polyurethane powder. With the gradual addition of ethanol, it can be observed that the polyurethane powder with a certain viscous coating sticks to each other Precipitated in gel form. Gradually reduce the stirring speed, pour out the mixed solution of the solvent and the precipitation agent in the reaction kettle, and the poured out solution can be distilled under reduced pressure to recover ethanol;

[0068] (4) the film-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com