Roller for a paper and/or carton machine

A technology of cardboard machine and paper machine, applied in paper machine, paper making, textile and paper making, etc., can solve the problem of low shock absorption efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

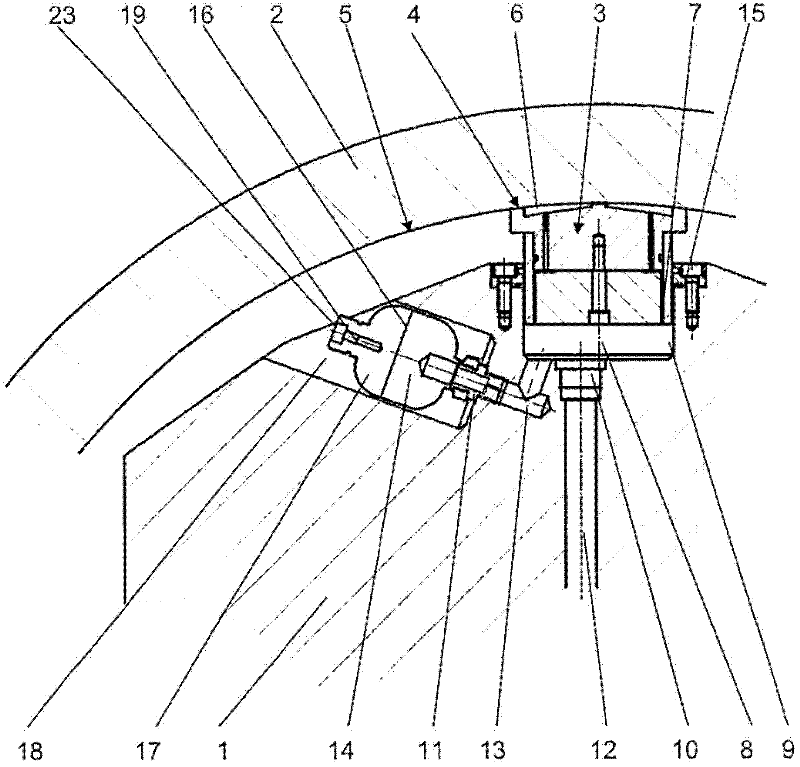

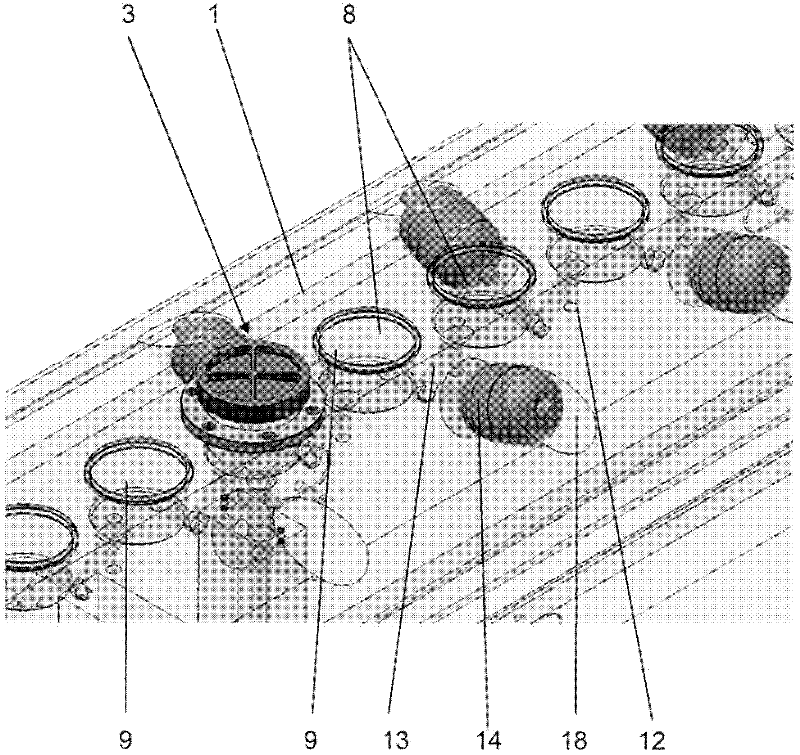

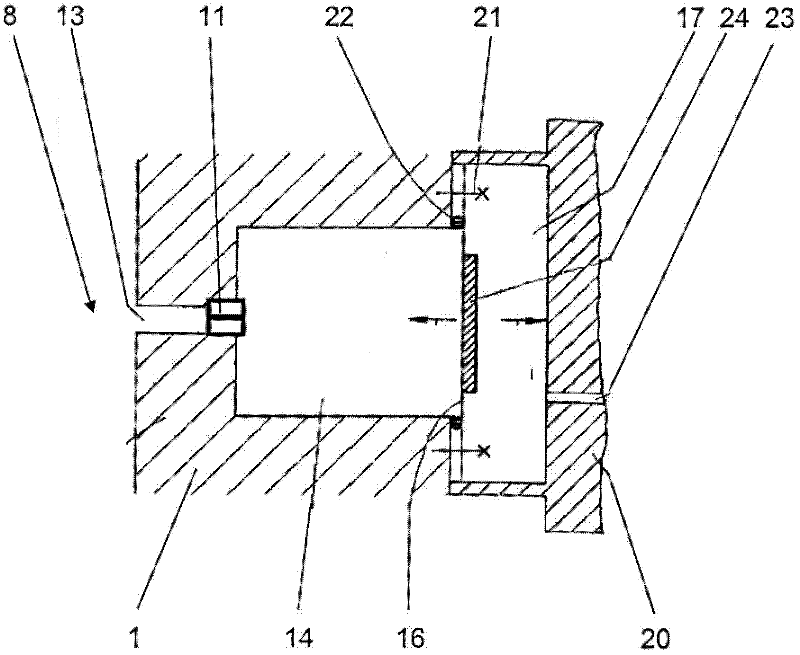

[0027] figure 1 A partial cross-section of a roller with a fixed support 1 and a surrounding roller sleeve 2 is shown. The bracket 1 penetrates the roller sleeve 2 axially here. The sleeve 2 is pressed radially outward by means of the supporting element 3. For this purpose, the support element 3 rests with the contact side 4 on the inner side 5 of the roller sleeve 2. The support element 3 has a pressure chamber 6 on its contact side 4, in which pressure chamber contains oil for forming an oil film between the contact side 4 and the inner side 5.

[0028] The support element 3 is guided in the pressure chamber 8 in a radially movable manner by a cylindrical projection 7. The pressure chamber 8 is connected to a pressure medium pipe 12 via a throttle 10, which is guided outward through the support 1 and used to provide the pressure chamber 8 with a pressure medium under pressure, such as pressure fluid.

[0029] The position of the support element 3 or the support 1 is determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com