Spatial hydraulic loader with two-motion-range movable arm and two-motion-range scraper pan

A mobility, bucket technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of inflexible movements, low work efficiency, limited work space, etc., and achieve large work space, high work efficiency, and mechanical Output track flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

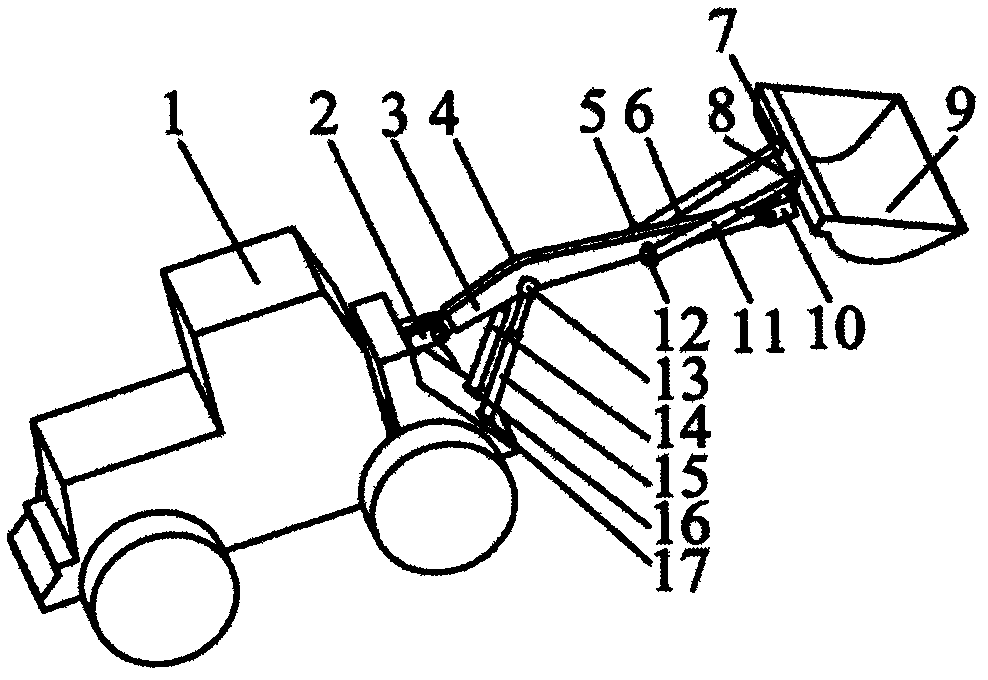

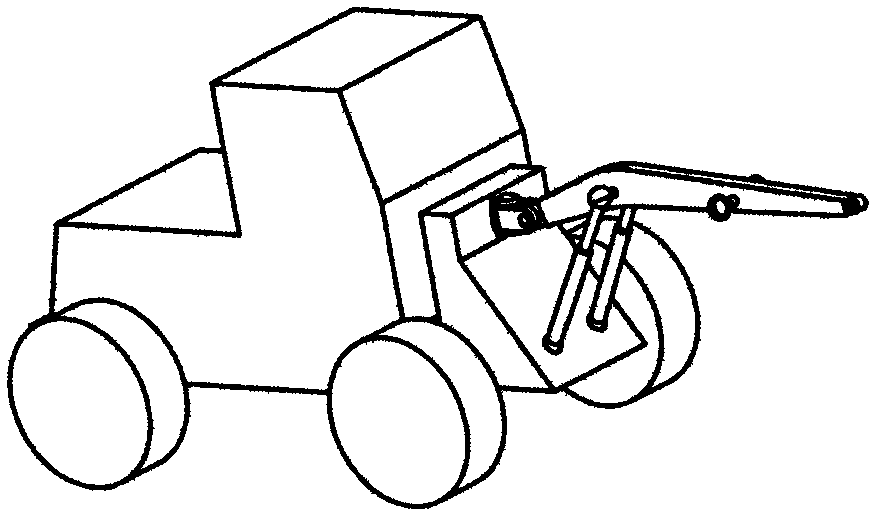

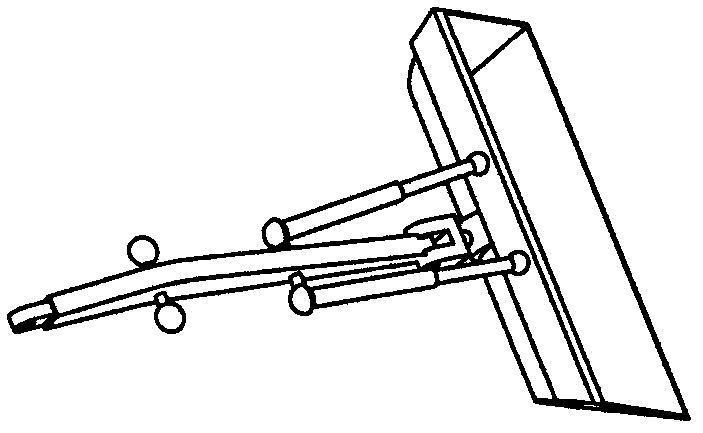

[0017] control figure 1 , the present invention achieves the above object through the following technical solutions: a hydraulic loader with a two-degree-of-movement boom and two-degree-of-movement bucket space, including a two-dimensional rotating boom mechanism and a two-dimensional rotating bucket mechanism.

[0018] control figure 1 , 2 , the two-dimensional rotating arm mechanism is composed of a two-dimensional rotating arm 3 , a first hydraulic cylinder 14 and a second hydraulic cylinder 15 . The two-dimensional rotating arm 3 is connected to the frame 1 through the first Hooke hinge 2, one end of the first hydraulic cylinder 14 is connected to the frame 1 through the first spherical pair 16, and the other end of the first hydraulic cylinder 14 is connected to the frame 1 through the second spherical pair 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com