Method and device for measuring equal precision frequency of single coil vibrating wire instrument

A technology of frequency measurement and equal precision, applied in measurement devices, instruments, electrical devices, etc., can solve the problems of inability to complete the measurement and reduce the measurement accuracy, and achieve the effect of simple and feasible measurement method, improved reliability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

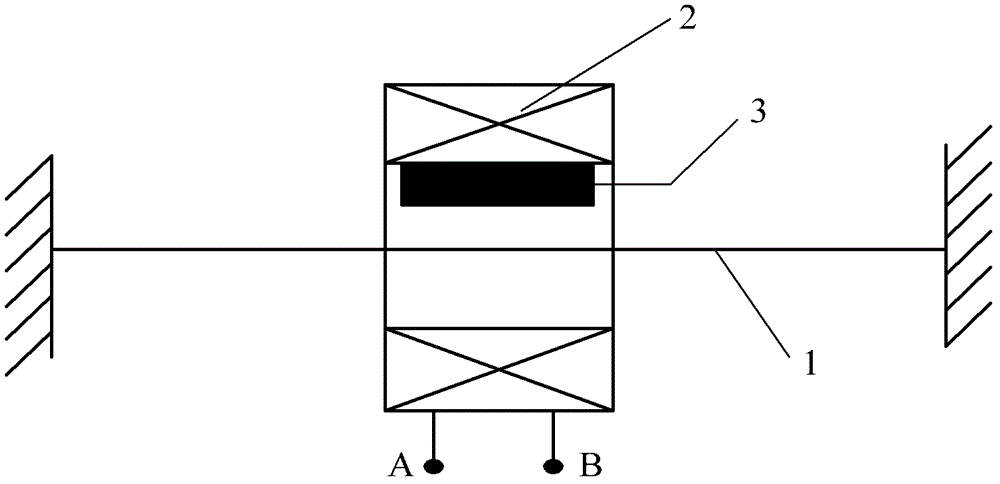

[0032] The present invention will be described below in conjunction with the accompanying drawings.

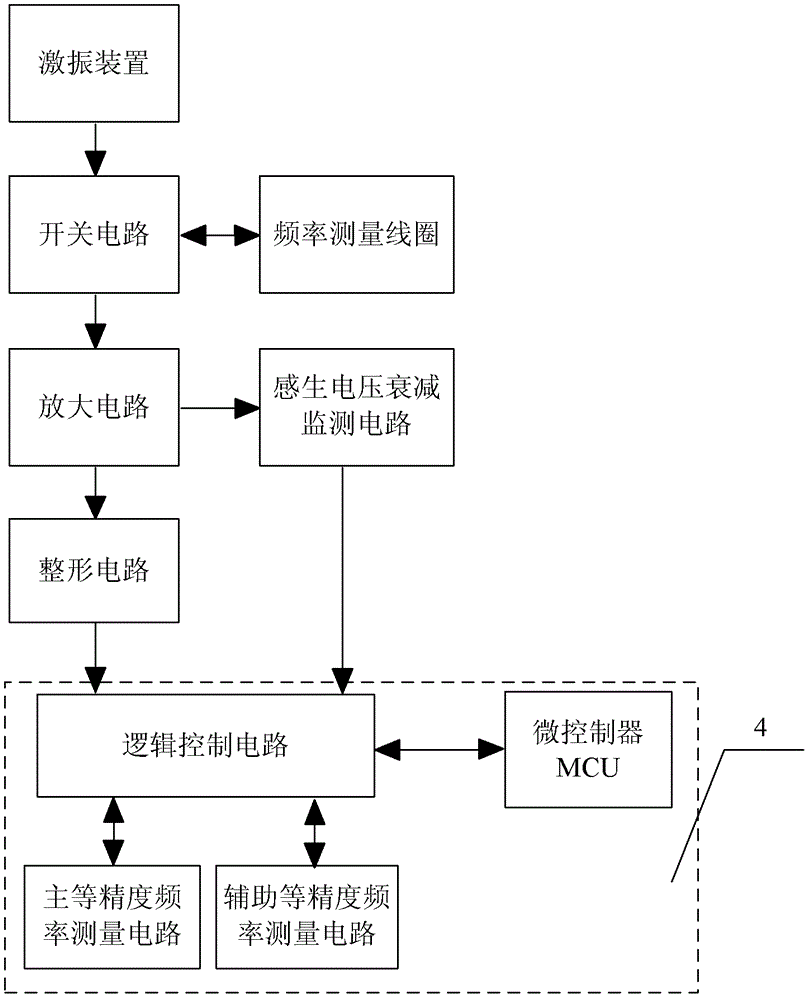

[0033] figure 2 It is a schematic diagram of the preferred structure of the equal-precision frequency measuring device of the single-coil vibrating wire instrument of the present invention. The device includes an excitation device, a switch circuit, an amplifying circuit, a shaping circuit, an induced voltage attenuation monitoring circuit, and an equal-precision frequency measurement circuit 4, wherein the excitation device includes a signal generator, and the switch circuit divides the signal generator and amplifying The circuits are respectively connected with the frequency measuring coils in the single-coil vibrating wire instrument. The time division is specifically that the switch circuit is used as a line selection switch circuit for exciting and picking up vibration. When the switch circuit is first connected to the signal generator and the frequency measurement coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com