Workbench position measuring system

A measurement system and workbench technology, applied in the field of measurement systems, can solve problems such as low integration and complex layout of interferometer measurement systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. Throughout the description, like reference numerals refer to like parts.

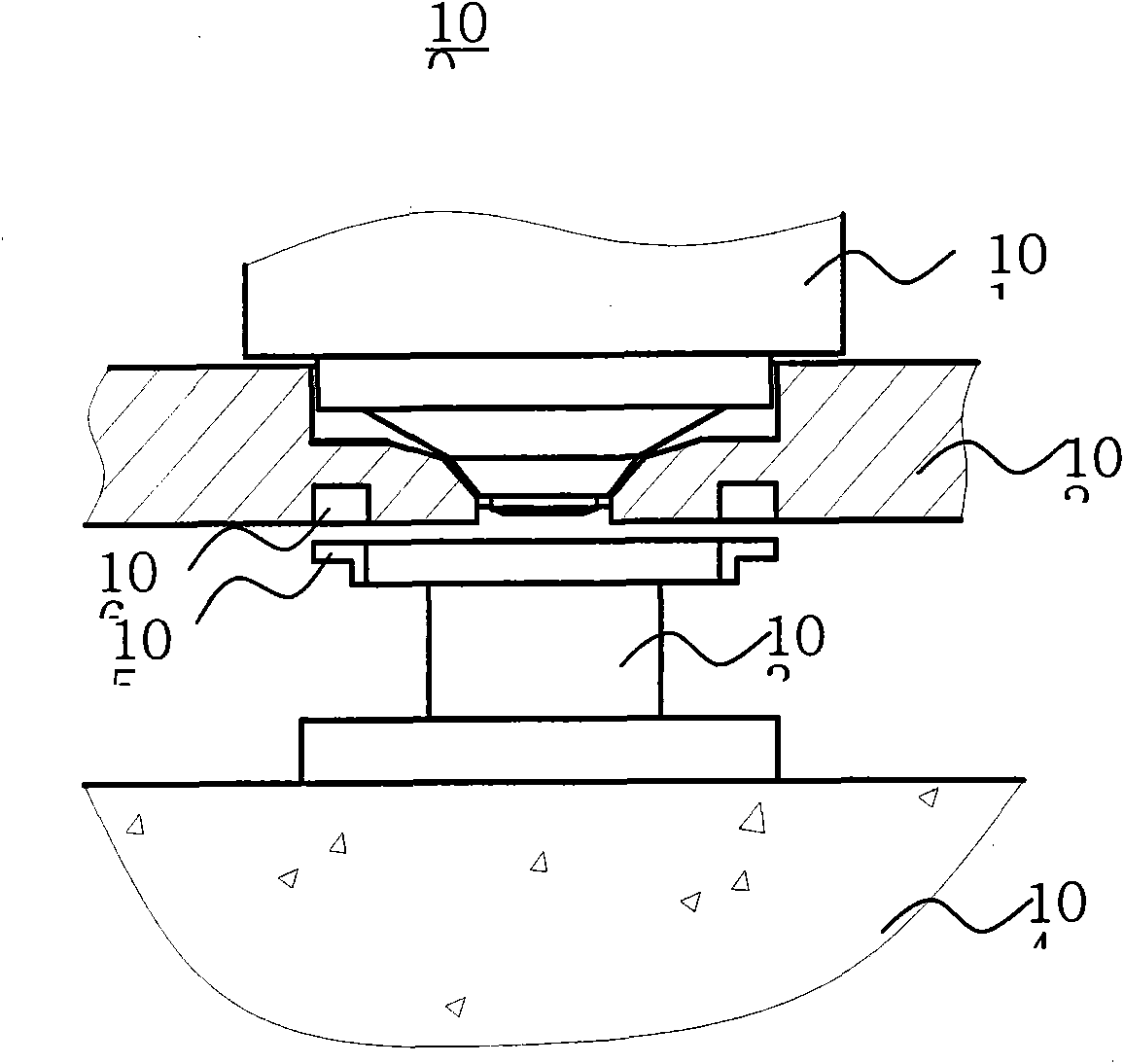

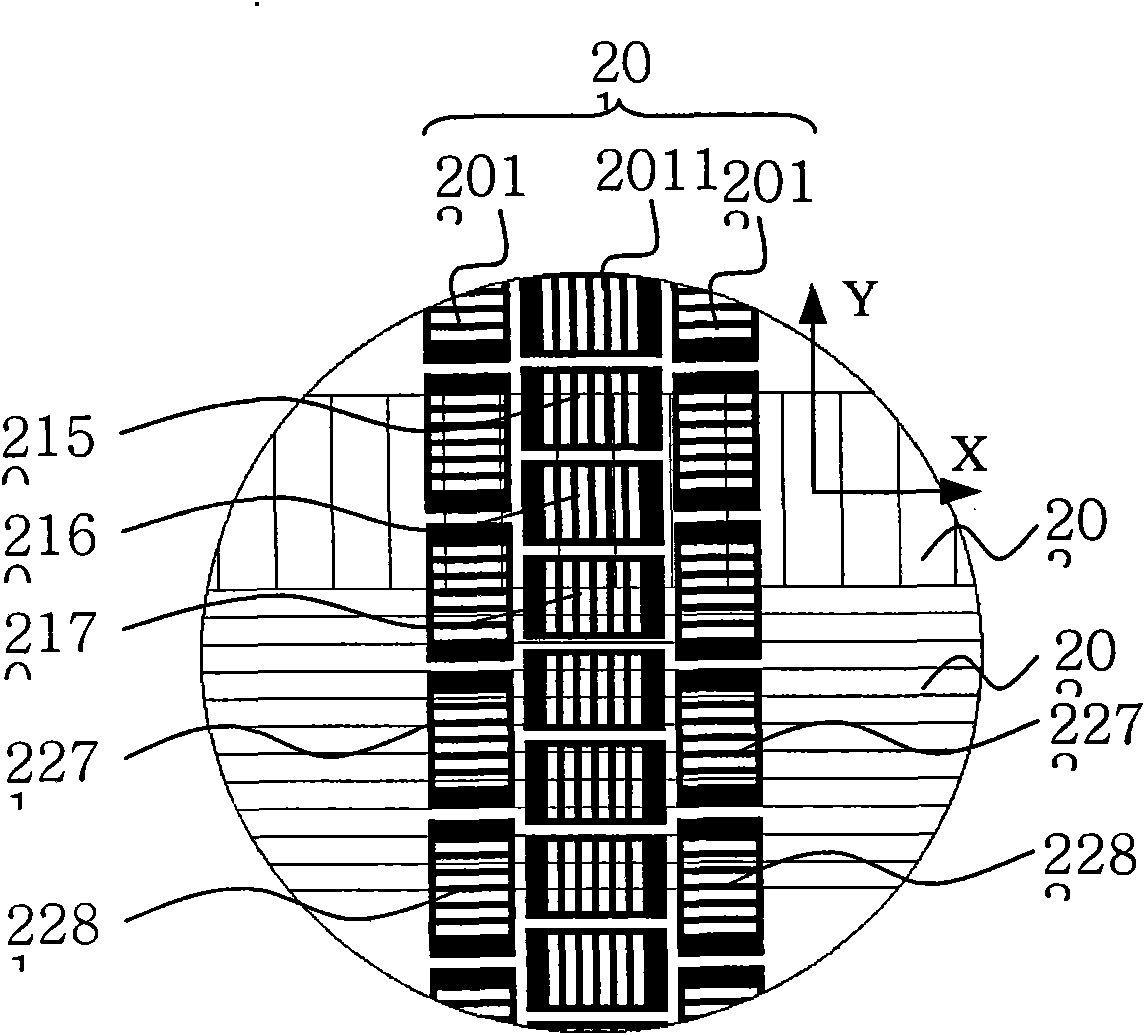

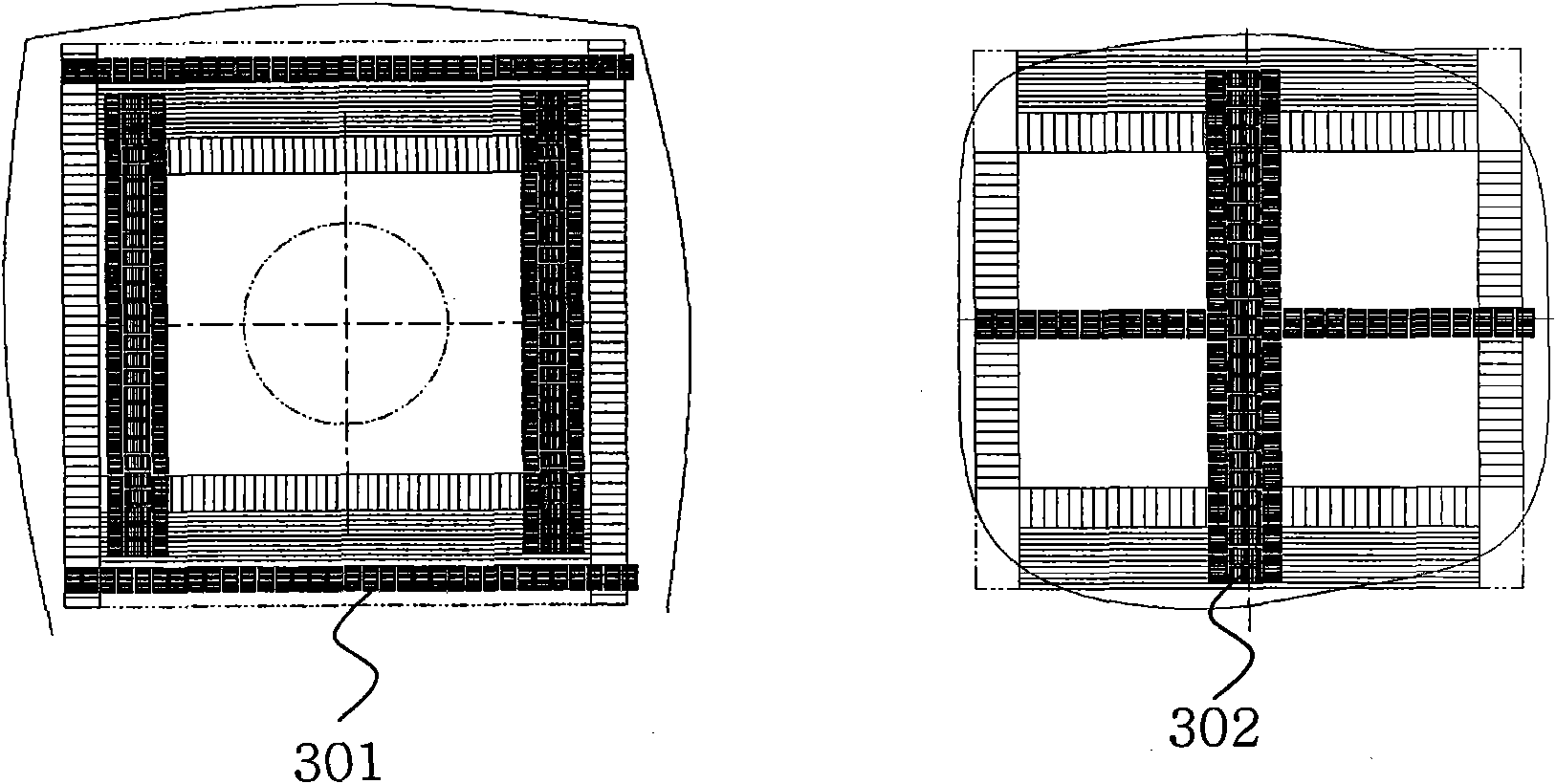

[0016] The workbench position measurement system composed of two-dimensional grating ruler and multiple rows of reading heads can measure the movement of the workbench stably, effectively and with high precision. The workbench position measurement system has a high degree of integration, is relatively independent and complete, and is subject to other subsystems. The influence of repair and maintenance is small. In addition, the structure and layout of the measurement system are simpler than those of the laser interferometer measurement system, and the requirements for design adjustment are also lower.

[0017] The method for measuring the movement information of the wafer carrier of the lithography machine can monitor the environmental impact in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com