Drum type non-excitation tapping switch with modularization assembling structural form

A structural form and tap changer technology, applied in the direction of prior contact arrangements, etc., can solve the problems of electric field leakage in the insulating cylinder 10, the strength of the insulating cylinder 10 is reduced, and the installation of electrical components is difficult, so as to save processing time and tool costs. The effect of simplifying production management and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples further describe the present invention, but the examples are only for illustrating the present invention rather than limiting the present invention.

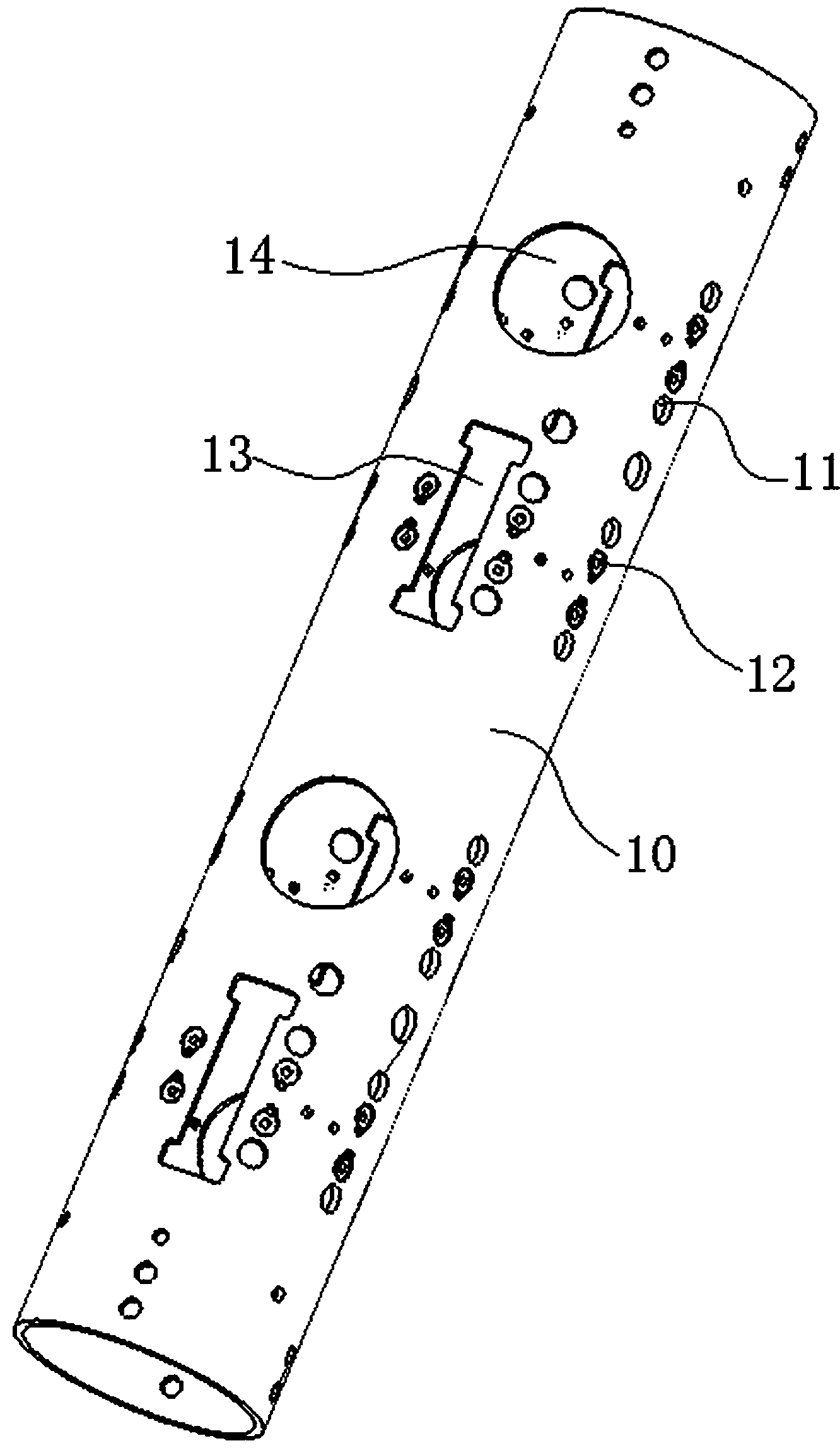

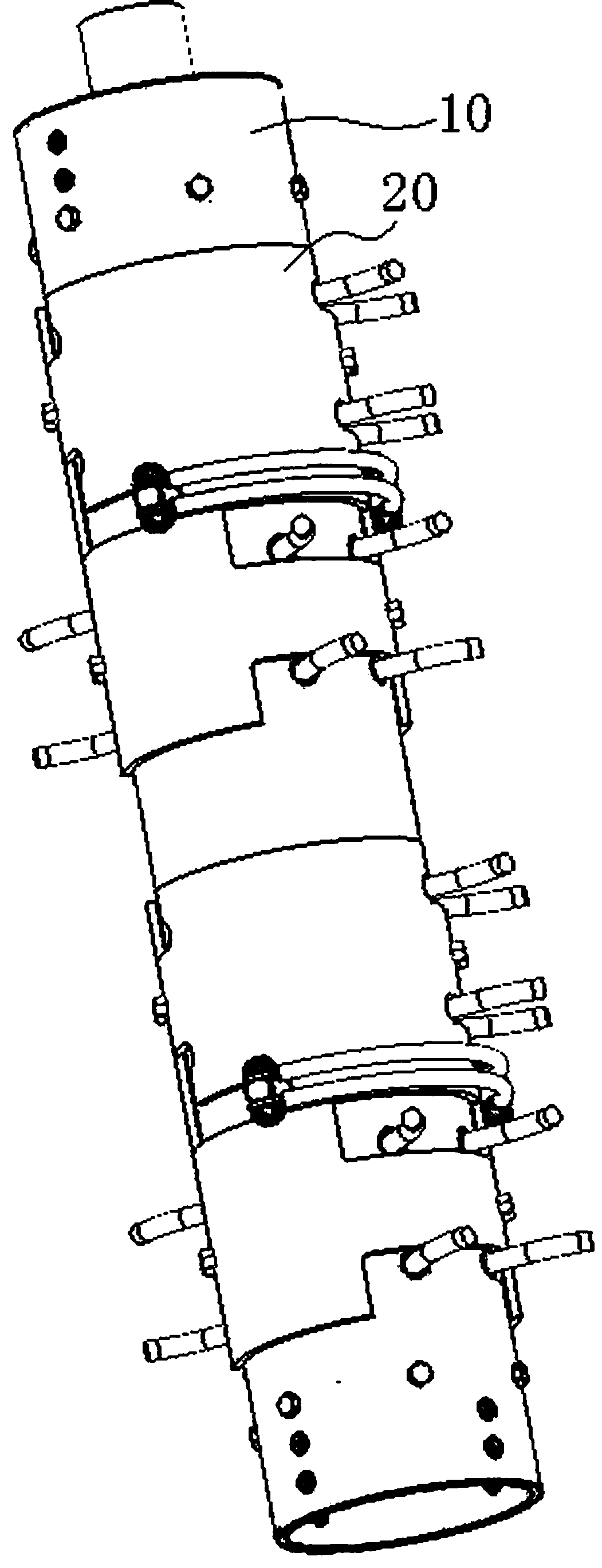

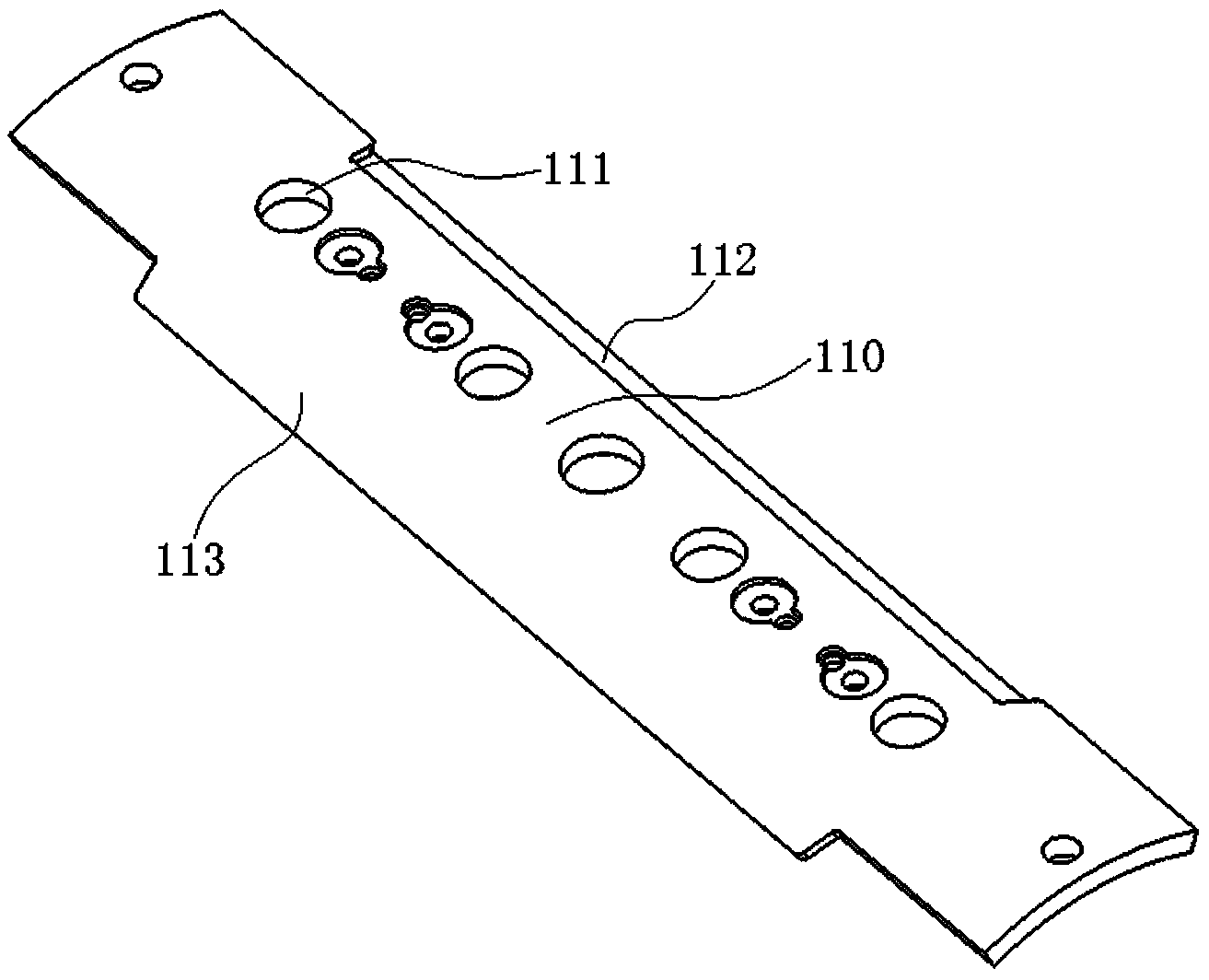

[0031] see image 3 , the insulating barrel in the assembled modular drum-type off-excitation tap-changer of the present invention is divided into 8 pieces with a central angle of 45° according to the degrees of distribution of the off-excitation tap-changer static contacts (not shown in the figure) on the switch circumference. Insulating arc-shaped plates 110, each insulating arc-shaped plate 110 adopts SMC insulating material and is molded by one-time hot pressing, and various holes 111 and structural requirements on it are also hot-pressed by the mold at one time, without mechanical cutting.

[0032] One side of each insulating arc-shaped plate 110 is provided with an overlapping groove 112 according to the length of the insulating arc-shaped plate 110, and an overlapping edge 113 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com