Method for depositing buffer material on framework of flat-panel display

A flat-panel display and cushioning material technology, which is applied to the rack/frame structure, the device for coating liquid on the surface, and the pre-treatment surface, etc., can solve the problems that it is difficult to ensure uniform thickness of the deposited buffer material, and the liquid crystal display is easy to be polluted. Achieve the effect of reducing manpower, reducing defective rate, and achieving adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

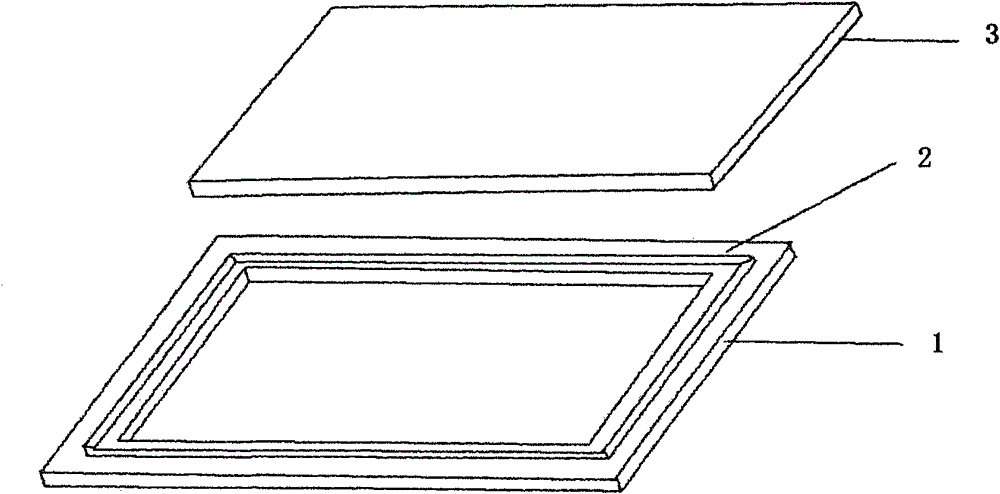

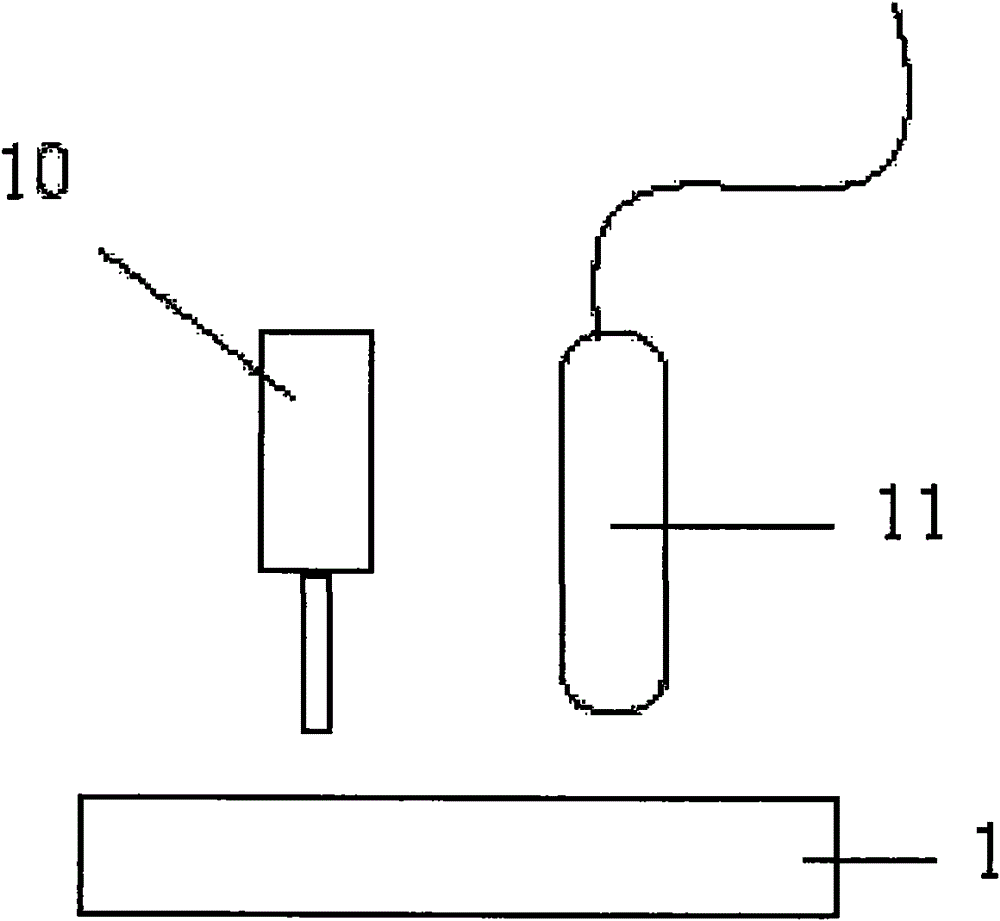

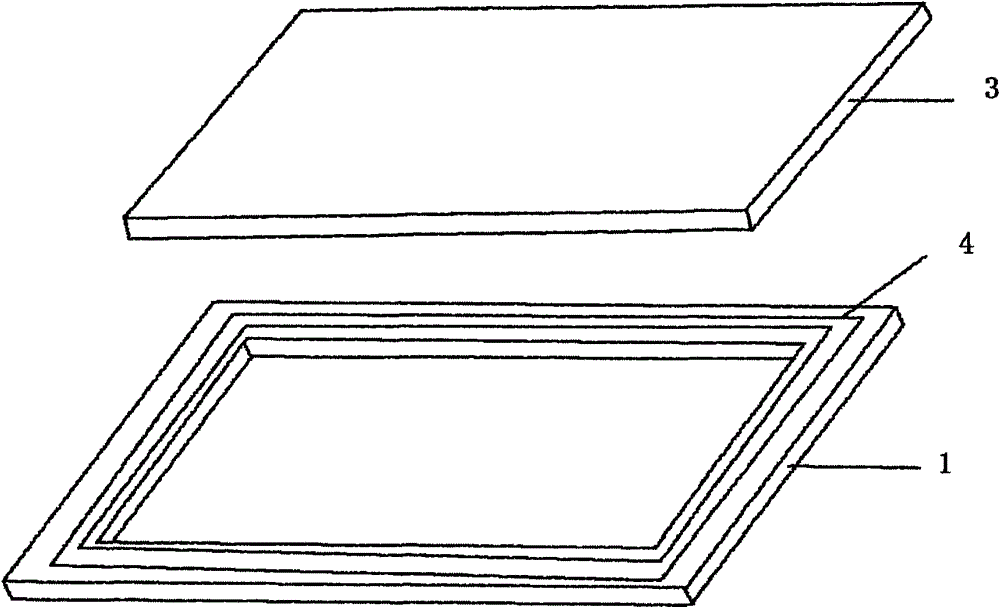

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing, a kind of method for depositing cushioning material on the frame of flat panel display, the method comprises the following steps: (a) utilize injection device, spray photohardenable composition on frame; ( b) irradiating and hardening the photocurable composition sprayed on the frame with ultraviolet rays, thereby forming an elastic photocurable buffer material; (c) adhering a transparent plate on the photocurable buffer material. In an actual process, according to the size and width of the frame, the spraying device used in step (a) can adjust the spraying amount of the photocurable composition. The line width and line height of the cushioning material after hardening can be applied to various designs according to the size and type of the frame, so it is not limited. Specifically, the line width is preferably 0.5-5 mm, and the height is preferably 0.5-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com