Production method of corrugated gas collecting pipeline member for air-conditioner

A production method and gas collecting pipe technology are applied in the production field of corrugated gas collecting pipe fittings for air conditioners, and can solve problems such as dead bending, difficult assembly, and impact on air conditioner performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

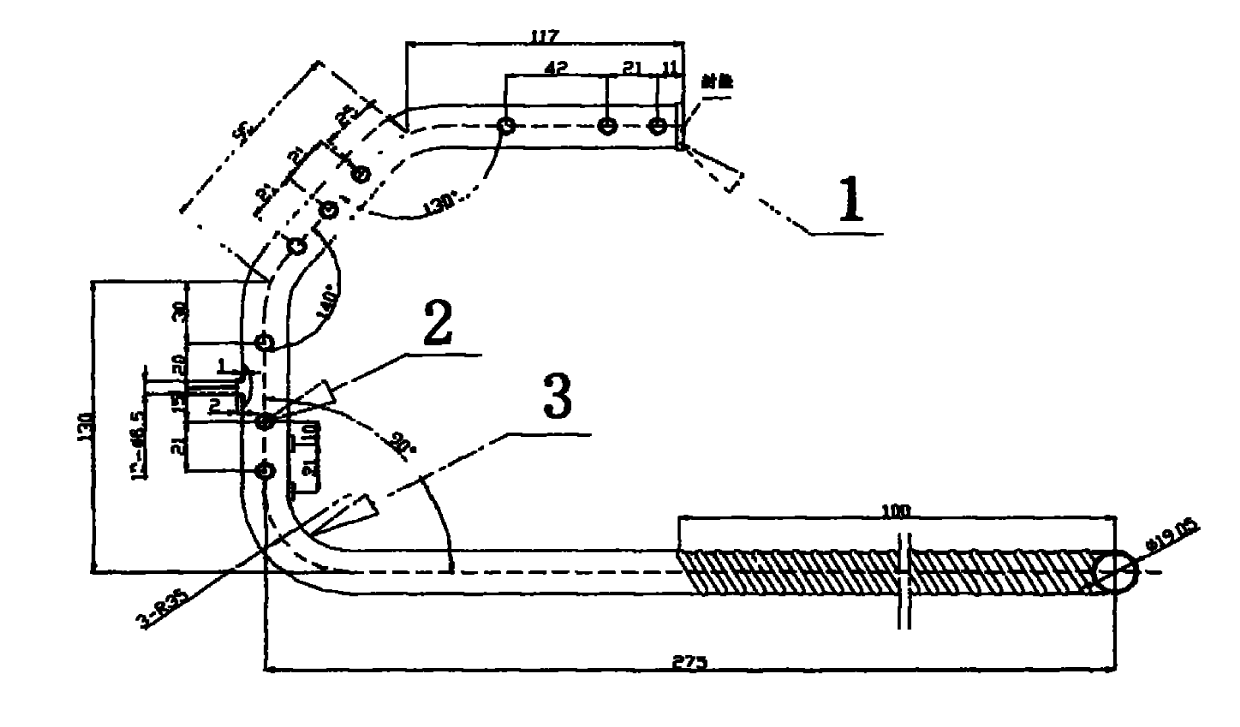

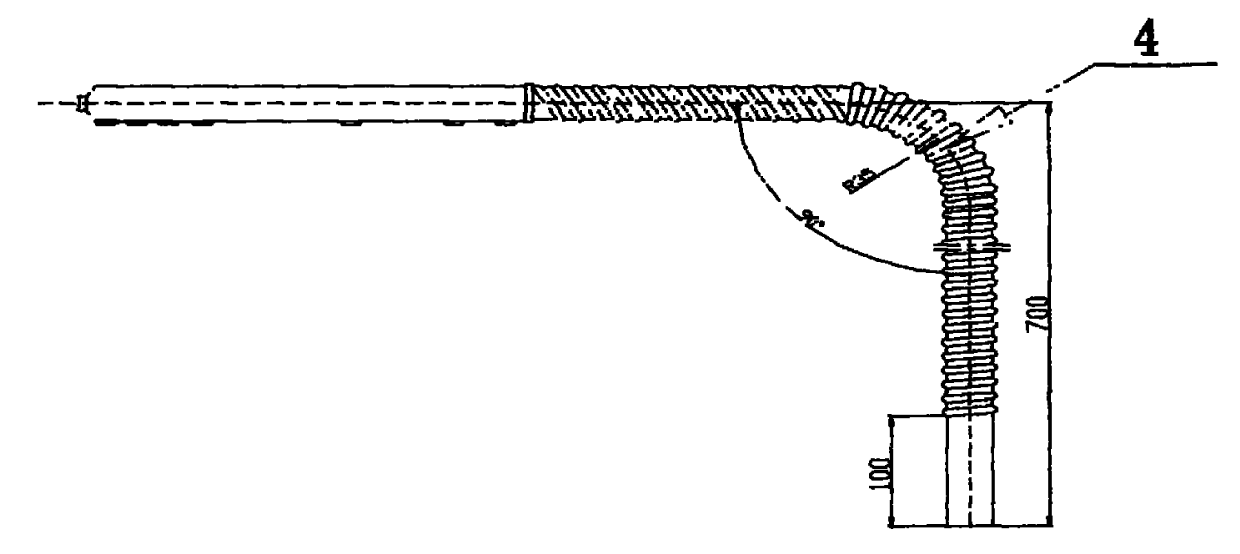

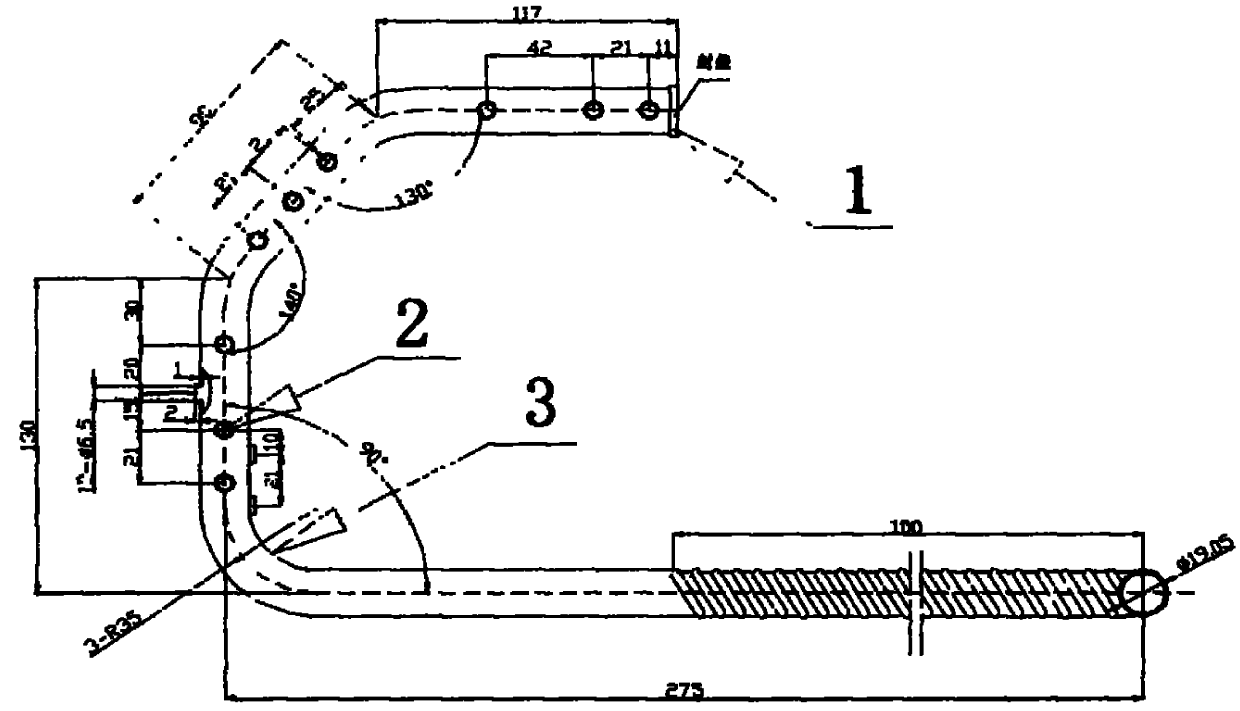

[0017] Embodiment 1: Under the premise of the prior art, the copper tube is first processed into a corrugated tube, such as figure 1 As shown in the figure, the corrugated wheel and other auxiliary equipment are combined, and the processing length is automatically controlled by the travel switch, and finally qualified corrugated pipe products can be produced. The positioning point is used to pull out the table. The table is pulled out by positioning a hole with a diameter of φ3.2, turning a hole with an inner diameter of φ6.5 and a table height of 2.5mm, and then adjusting the hole to a hole with an inner diameter of φ6.5 and a table height of 2mm. Repeat the bending of 140 degrees again to locate the puller, and the third time to bend 130 degrees to locate the puller. Then anneal the product, and focus on the bending of the thread to ensure the bending range and number of bending, and the other parts are treated lightly. Bending bellows with special molds to meet the bending...

Embodiment 2

[0018] Example 2: First, the copper pipe is processed into a corrugated pipe, which is combined with corrugated wheels and other auxiliary equipment, and the processing length is automatically controlled by the travel switch. Finally, qualified corrugated pipe products can be produced, and then the dial table is determined and the pull table is pulled out. The position of the machine is determined, then it is bent through a special mold, and the table is pulled out at the positioning point. The table is pulled out by positioning a hole of φ4.0, turning a hole with an inner diameter of φ7.0, and a table height of 3mm, and then calibrating the hole as A hole with an inner diameter of φ7.0 and a table height of 2.5mm. Repeat the bending of 150 degrees again to locate the pull-out table, and the third bend of 140 degrees to locate the pull-out table. Then anneal the product, and focus on the bending of the thread to ensure the bending range and number of bending, and the other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com