Water lifting platform

A lifting table and lifting platform technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of thousands of tons or even tens of thousands of tons, complex launching operation, large component shape, etc., so that it is not easy to damage and low operating cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

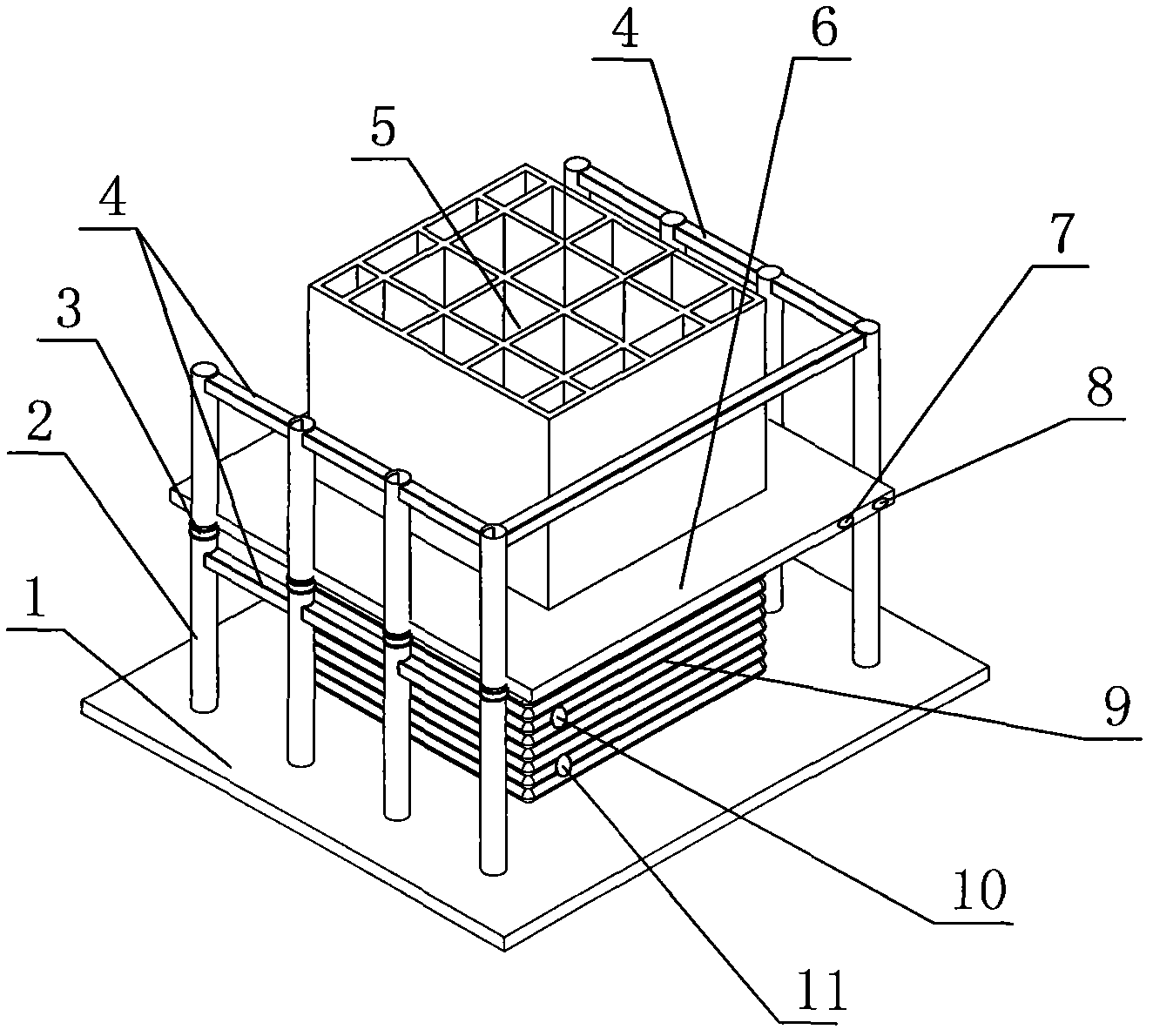

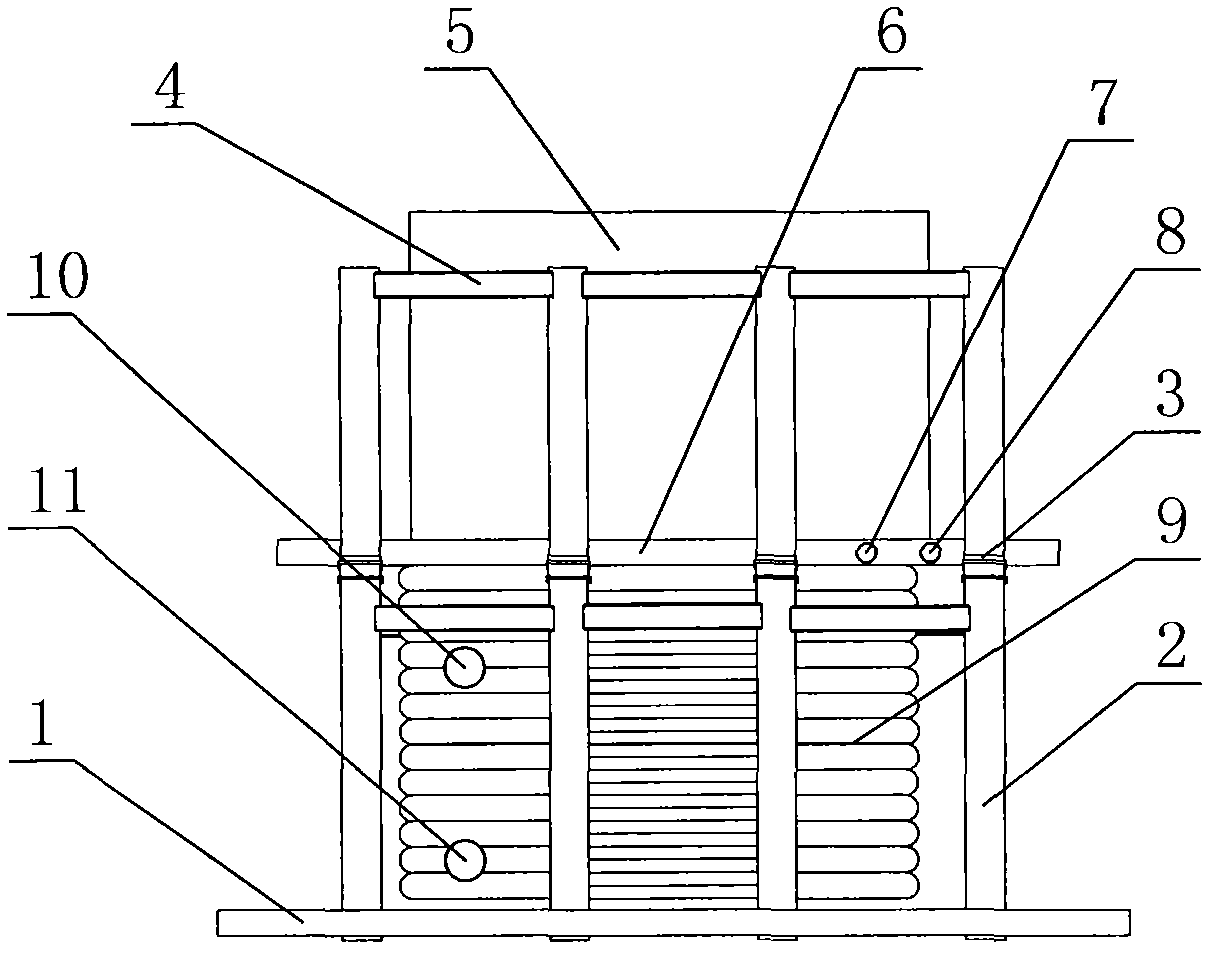

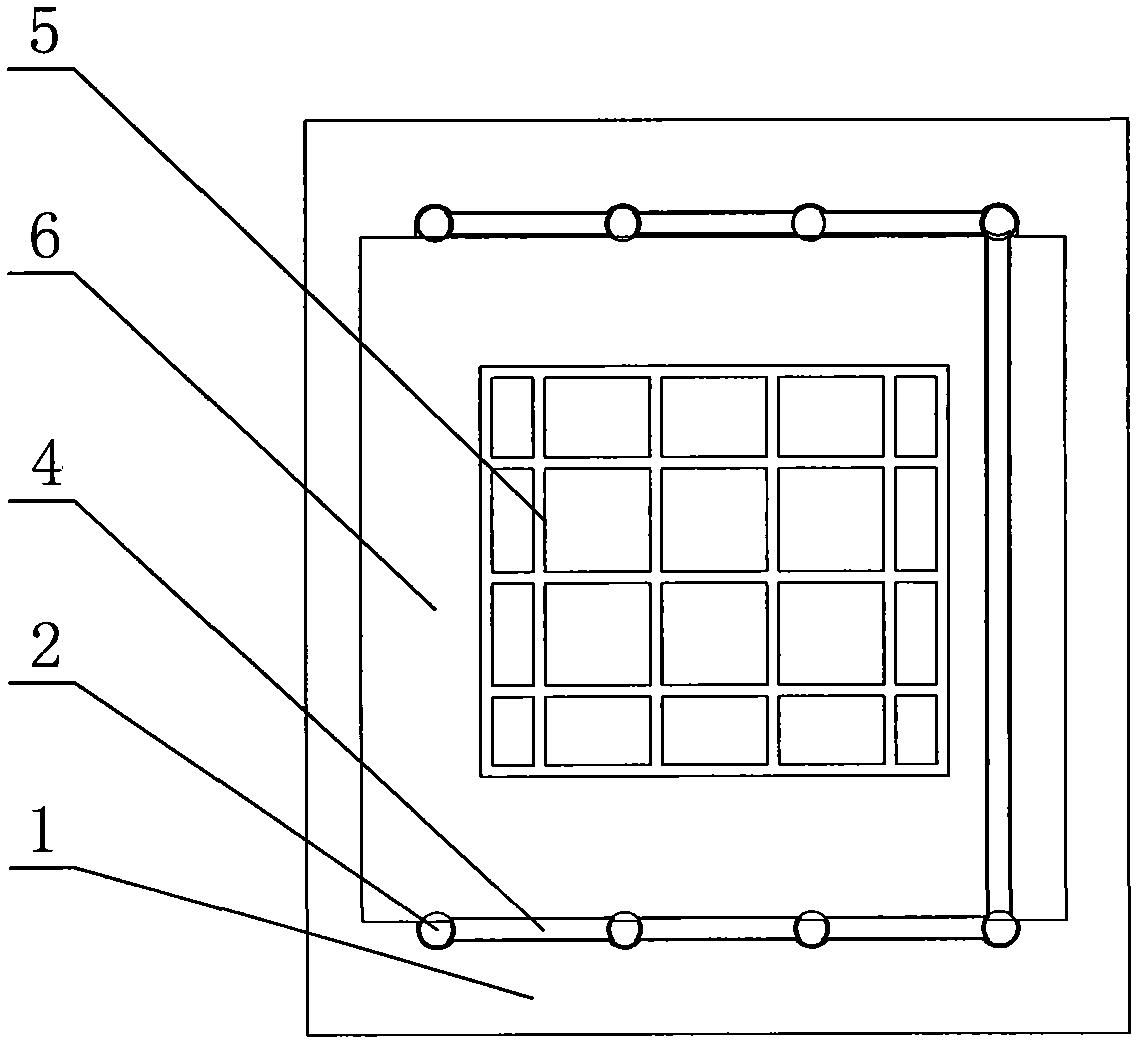

[0034] A kind of underwater lifting platform, such as figure 1 , figure 2 , image 3 As shown, it includes a base 1 and a frame installed on the base 1, and an airbag delivery device is arranged in the frame. The air bag delivery device includes an air bag 9 arranged at the bottom of the frame and a lifting platform 6 connected to the upper end of the air bag 9 . The lower part of the airbag 9 is provided with an airbag inlet and outlet valve 11, and the upper part is provided with an airbag inlet and outlet valve 10. In this embodiment, the airbag inlet and outlet valve 10 communicates with the air compressor. The lifting platform 6 is provided with a platform inlet and outlet valve 7 and a platform inlet and outlet valve 8. In this embodiment, the platform inlet and outlet valve 8 communicates with the air compressor. The airbag used in the present invention is a multi-layer airbag or a folded airbag with good expandability, which can maximize the delivery distance.

[...

Embodiment 2

[0041] A kind of underwater lifting platform, such as Figure 4 , Figure 5 , Image 6 As shown, it includes a base 1 and a frame installed on the base 1, and an airbag delivery device is arranged in the frame. The air bag delivery device includes an air bag 9 arranged at the bottom of the frame and a lifting platform 6 connected to the upper end of the air bag 9 . The lower part of the airbag 9 is provided with an airbag inlet and outlet valve 11, and the upper part is provided with an airbag inlet and outlet valve 10. In this embodiment, the airbag inlet and outlet valve 10 communicates with the air compressor. The lifting platform 6 is provided with a platform inlet and outlet valve 7 and a platform inlet and outlet valve 8. In this embodiment, the platform inlet and outlet valve 8 communicates with the air compressor. The airbag used in the present invention is a multi-layer airbag or a folded airbag with good expandability, which can maximize the delivery distance.

...

Embodiment 3

[0048] A kind of underwater lifting platform, such as Figure 7 , Figure 8 , Figure 9 As shown, it includes a base 1 and a frame installed on the base 1, and an airbag delivery device is arranged in the frame. The air bag delivery device includes an air bag 9 arranged at the bottom of the frame and a lifting platform 6 connected to the upper end of the air bag 9 . The lower part of the airbag 9 is provided with an airbag inlet and outlet valve 11, and the upper part is provided with an airbag inlet and outlet valve 10. In this embodiment, the airbag inlet and outlet valve 10 communicates with the air compressor. The lifting platform 6 is provided with a platform inlet and outlet valve 7 and a platform inlet and outlet valve 8. In this embodiment, the platform inlet and outlet valve 8 communicates with the air compressor. The airbag used in the present invention is a multi-layer airbag or a folded airbag with good expandability, which can maximize the delivery distance.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com