Two-way flow type check valve and ultra-pure water system

A flow type, check valve technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve problems such as easy breeding of bacteria, inability of ultrapure water to flow, affecting the quality of ultrapure water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

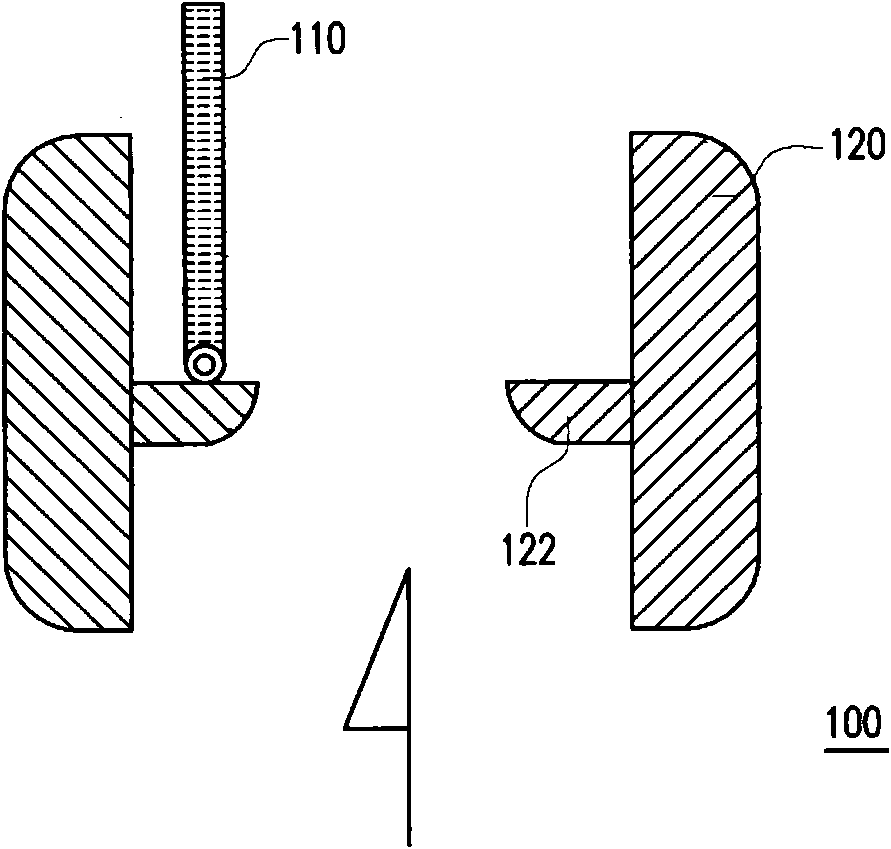

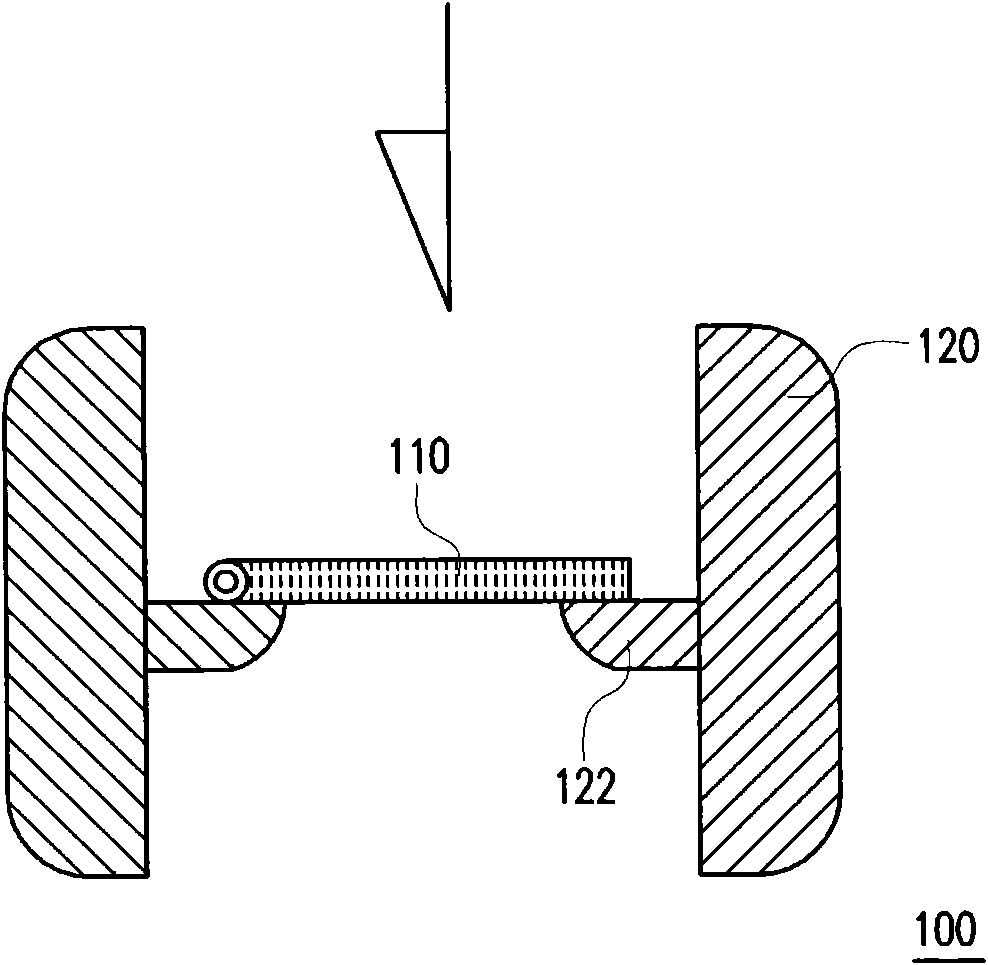

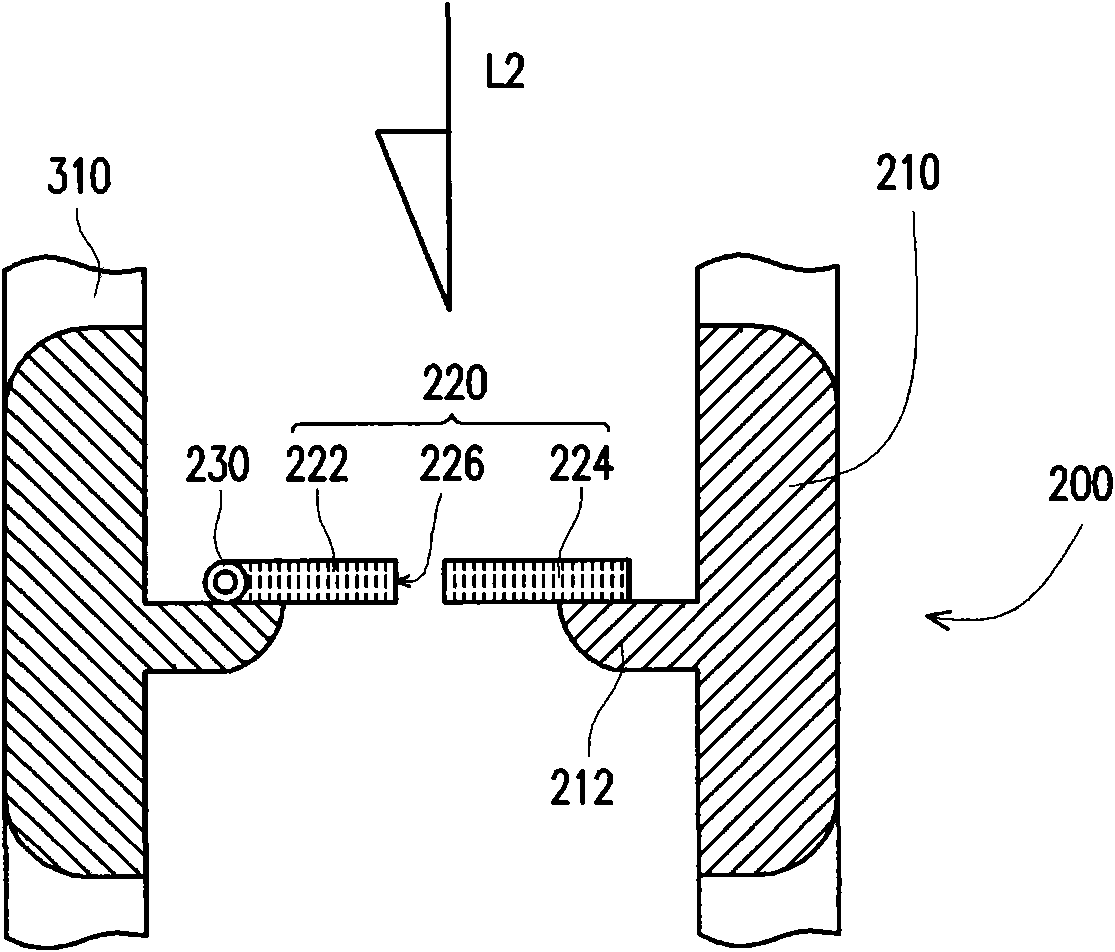

[0031] Figure 2A It is a schematic diagram when the bidirectional flow check valve of an embodiment of the present invention is closed, Figure 2B It is a schematic diagram when the two-way flow check valve of an embodiment of the present invention is opened, and Figure 2C A top view of a valve that is a two-way flow check valve. Please also refer to Figure 2A , Figure 2B and Figure 2C , the bidirectional flow check valve 200 of this embodiment includes a body 210 and a valve 220, wherein the body 210 has a support portion 212, and the valve 220 has a first end 222, a second end 224 and at least one return hole 226, and the return hole 226 is located between the first end 222 and the second end 224, and the first end 222 of the valve 220 can be arranged on the body 210 through a fixing member 230, and the second end 224 is suitable for bearing against the body 210 The support part 212. In particular, the two-way flow check valve 200 is installed in a pipeline 310, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com