Thermopile infrared sensor and manufacture method thereof

An infrared sensor and thermopile technology, applied in the field of infrared sensors, can solve the problems of reduced yield and incompatible IC technology, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

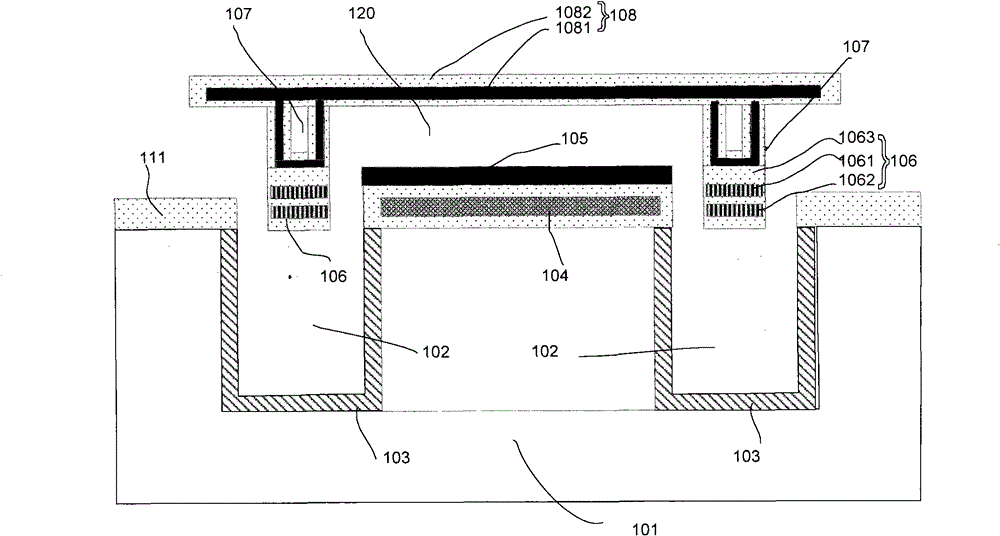

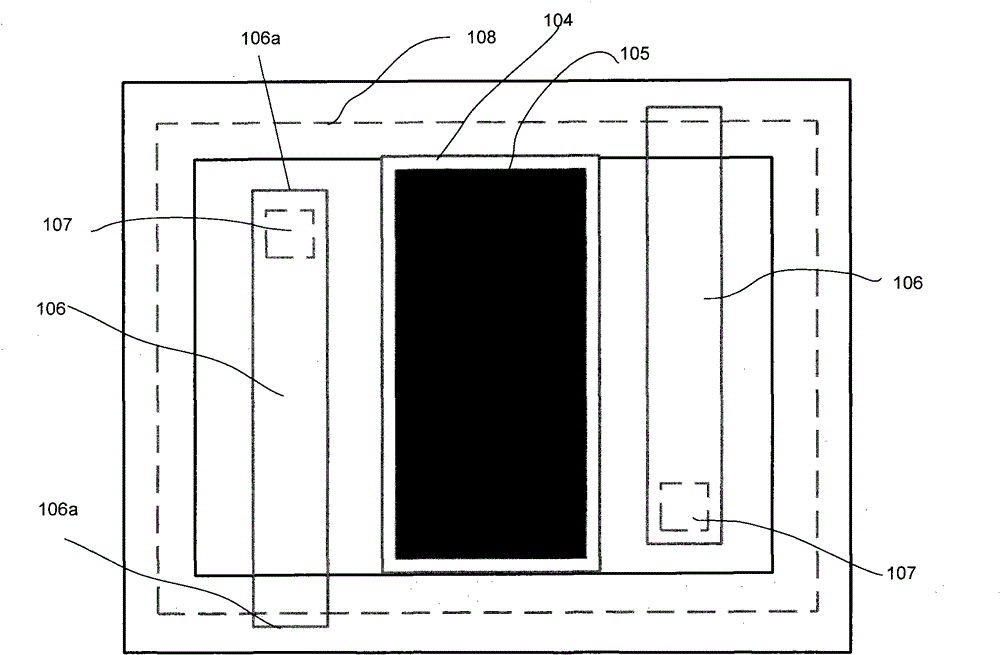

[0057] figure 2 It is a structural sectional view of a thermopile infrared sensor in this embodiment, image 3 for figure 2 In the top view of the structure of the thermopile infrared sensor, in order to clearly show the invention point, only one detection unit is shown in the figure, and the actual thermopile infrared sensor is composed of a plurality of such detection units.

[0058] As shown in the figure, the thermopile infrared sensor includes:

[0059] a substrate 101, the substrate 101 has a groove 102 therein;

[0060]The absorbing layer 108 is located above the substrate 101 and has a certain distance from the surface of the substrate 101;

[0061] The reflective layer 105 is formed on the surface of the substrate outside the trench 102, completely under the absorbing layer 108, and has a cavity 120 between it and the absorbing layer 108;

[0062] The readout circuit layer 104 is located on the substrate surface below the reflective layer 105, and is used to out...

Embodiment 2

[0089] Figure 9 It is a cross-sectional view of the structure of the thermopile infrared sensor in this embodiment. As shown in the figure, the thermopile infrared sensor also includes: a substrate 201 with a groove 202, an absorbing layer 208 located above the substrate 201, a reflective layer 205 located on the surface of the substrate outside the groove, the The cavity 229 between the reflection layer 205 and the absorption layer 208, the cantilever beam 206 composed of thermocouple pairs, and the readout circuit layer 204 under the reflection layer.

[0090] The difference from Embodiment 1 is that: the substrate is an SOI substrate, which includes a bottom silicon layer, a buried oxide layer and a top silicon layer, and the trench 202 is located in the bottom silicon layer; the thermocouple pair is P Type single crystal silicon and N type single crystal silicon, or, the thermocouple pair is metal and single crystal silicon. Thus, both the P-type single crystal silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com