Full-automatic torque repetition deviation measuring system

A deviation measurement, fully automatic technology, applied in the direction of torque measurement, measuring device, power measurement, etc., can solve the problems of one-time forming that does not meet the measurement data, low work efficiency, and inability to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

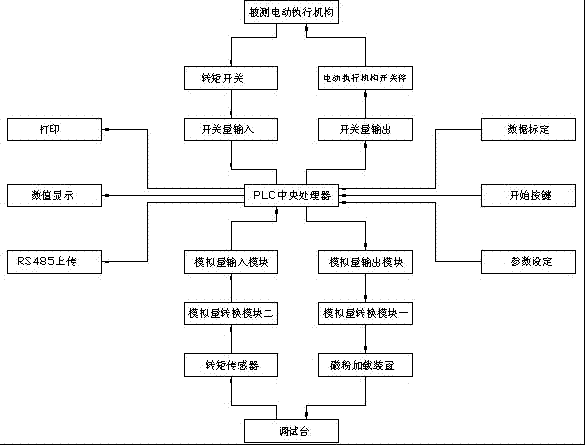

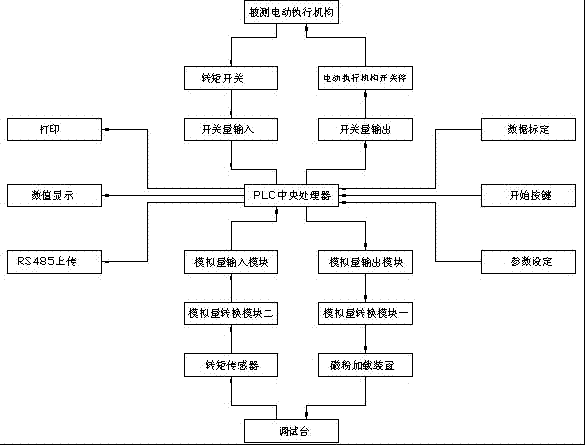

[0015] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, a fully automatic torque repeat deviation measurement system includes a PLC central processing unit, a torque acquisition circuit, a magnetic powder loading circuit, an RS485 bus, a start button, and an electric actuator control circuit. The PLC central processing unit It is s7-200 series 226CPU, the PLC central processing unit is respectively connected with the start button, torque acquisition circuit, magnetic powder loading circuit and electric actuator control circuit through the RS485 bus, and the magnetic powder loading circuit is connected with the torque acquisition circuit through the debugging platform .

[0016] The magnetic powder loading circuit includes an analog output module connected in sequence, an analog conversion module two and a magnetic powder loading device. The analog output module is s7-200 series EM232, and the analog output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com