Embossed test roller silica gel proofing method

A silica gel and embossing technology, which is applied in the field of embossed test roll silica gel proofing, can solve the problems of toxic gas, high energy consumption, and large material loss, and achieve the effect of small material loss, simple method, and good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment adopts following process steps:

[0022] (A) Clean the test roll: clean the roll surface of the test roll to remove the dirt and oil on the roll surface;

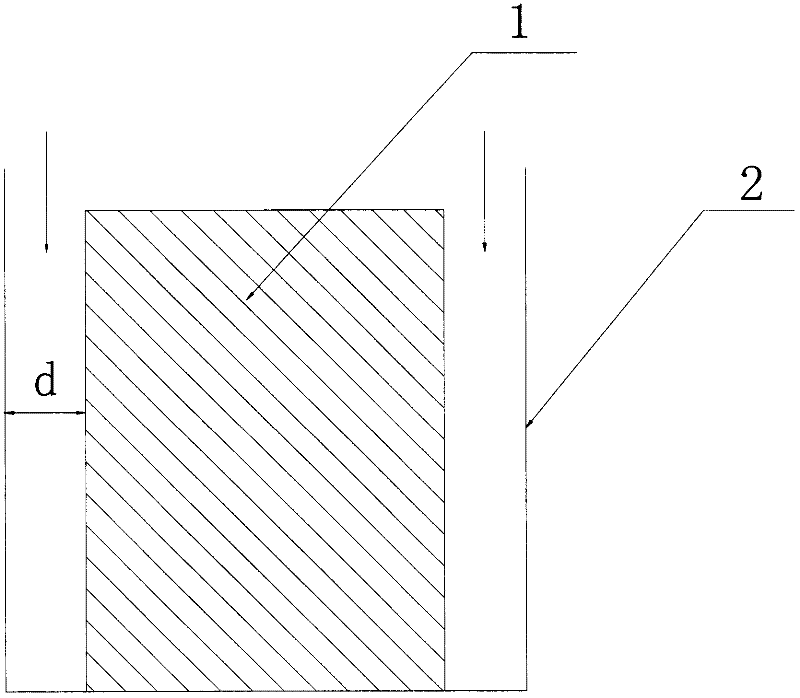

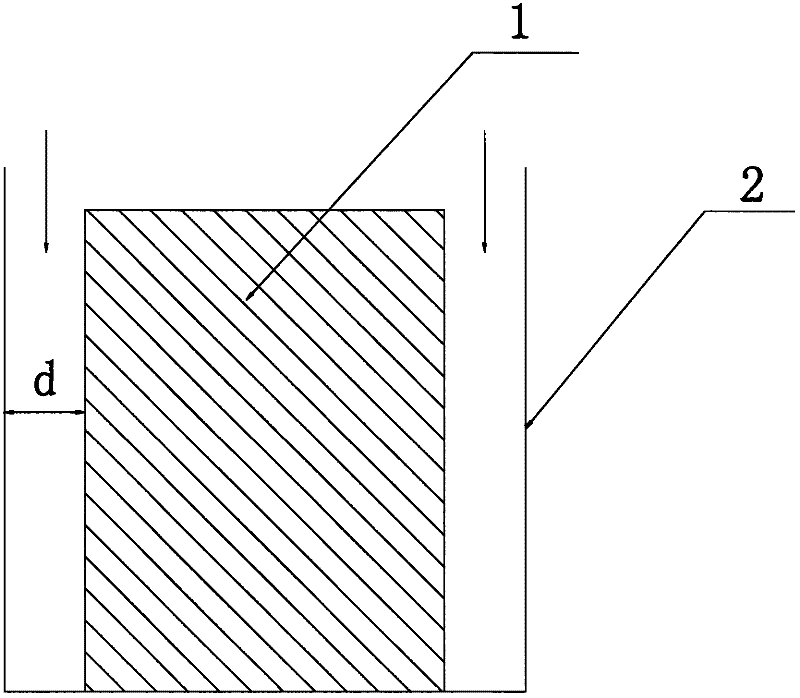

[0023] (B) Make the frame: position the test roll and frame around the test roll, such as figure 1 As shown, the gap between the frame 2 and the test roll 1 is d=2cm, and the height of the frame 2 is slightly higher than the test roll 1;

[0024] (C) Preparation of silica gel and foam removal: prepare release silica gel, then put it into a vacuum machine to evacuate and exhaust the air bubbles for 2 minutes, thereby obtaining the release silica gel of the fluid;

[0025] (D) Molding: Slowly pour the above-mentioned mold release silica gel fluid that has exhausted the air bubbles from the gap between the surrounding frame 2 and the test roll 1 into the surrounding frame 2, avoiding excessive pouring speed to generate air bubbles, until the entire test roll is covered until;

[0026] (E) Curin...

Embodiment 2

[0033] The present embodiment adopts following process steps:

[0034] (A) Clean the test roll: clean the roll surface of the test roll to remove the dirt and oil on the roll surface;

[0035] (B) Make the frame: position the test roll and frame around the test roll, such as figure 1 As shown, the gap between frame 2 and test roll 1 is d=1cm, and the height of frame 2 is slightly higher than test roll 1;

[0036] (C) Preparation of silica gel and defoaming: prepare demoulding silica gel, then put it into a pressure cylinder to defoam for 3 minutes, thereby obtaining the demoulding silica gel of fluid;

[0037] (D) Molding: Slowly pour the above-mentioned mold release silica gel fluid that has exhausted the air bubbles from the gap between the surrounding frame 2 and the test roll 1 into the surrounding frame 2, avoiding excessive pouring speed to generate air bubbles, until the entire test roll is covered until;

[0038] (E) Curing: place the above-mentioned test roll after...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap