Electrophoretic painting tool for automobile sidewall

An electrophoretic coating, automotive side technology, used in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of substandard side wall quality, rough surface of the paint film, and high difficulty in operation, and achieve improved production efficiency and paint film. Smooth, electrophoretic high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

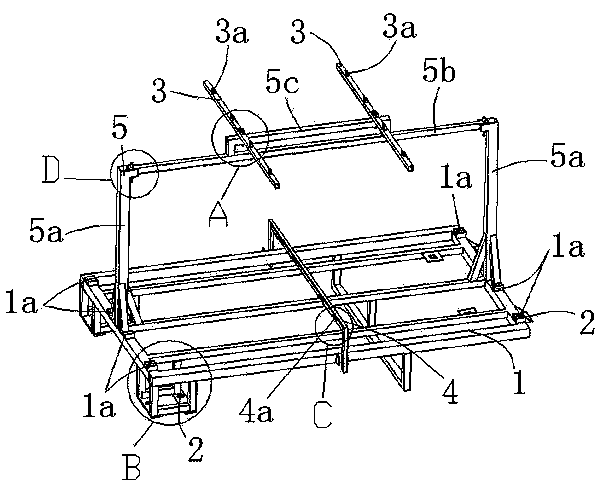

[0023] Such as figure 1 The tooling for the electrophoretic coating of the side wall of the car shown is mainly composed of a horizontal rectangular frame 1 , a mounting positioning hole 2 , and a side wall support rod 3 . The installation positioning holes 2 are arranged below the horizontal rectangular frame 1, and the number and positions thereof are set correspondingly to the fixture positioning parts on the electrophoretic coating production line.

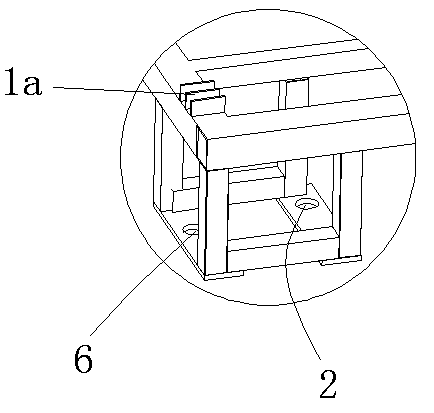

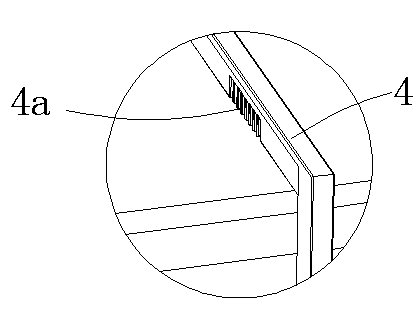

[0024] combine figure 1 , figure 2 , Image 6 It can be seen that the side support rod 3 extends left and right and is arranged above the horizontal rectangular frame 1, the side support rod 3 is connected with the horizontal rectangular frame 1 through the support beam 5, and the upper end of the side support rod 3 is provided with The upper card slot 3a. combine figure 1 , image 3 , Image 6 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com