Top-coal caving scraper conveyor with movable coal-collecting plate

A scraper conveyor, top coal caving technology, applied in the directions of underground transportation, transportation and packaging, earthwork drilling and mining, etc. problems, to achieve the effect of reducing investment, improving the recovery rate of coal resources, and increasing the space for coal falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

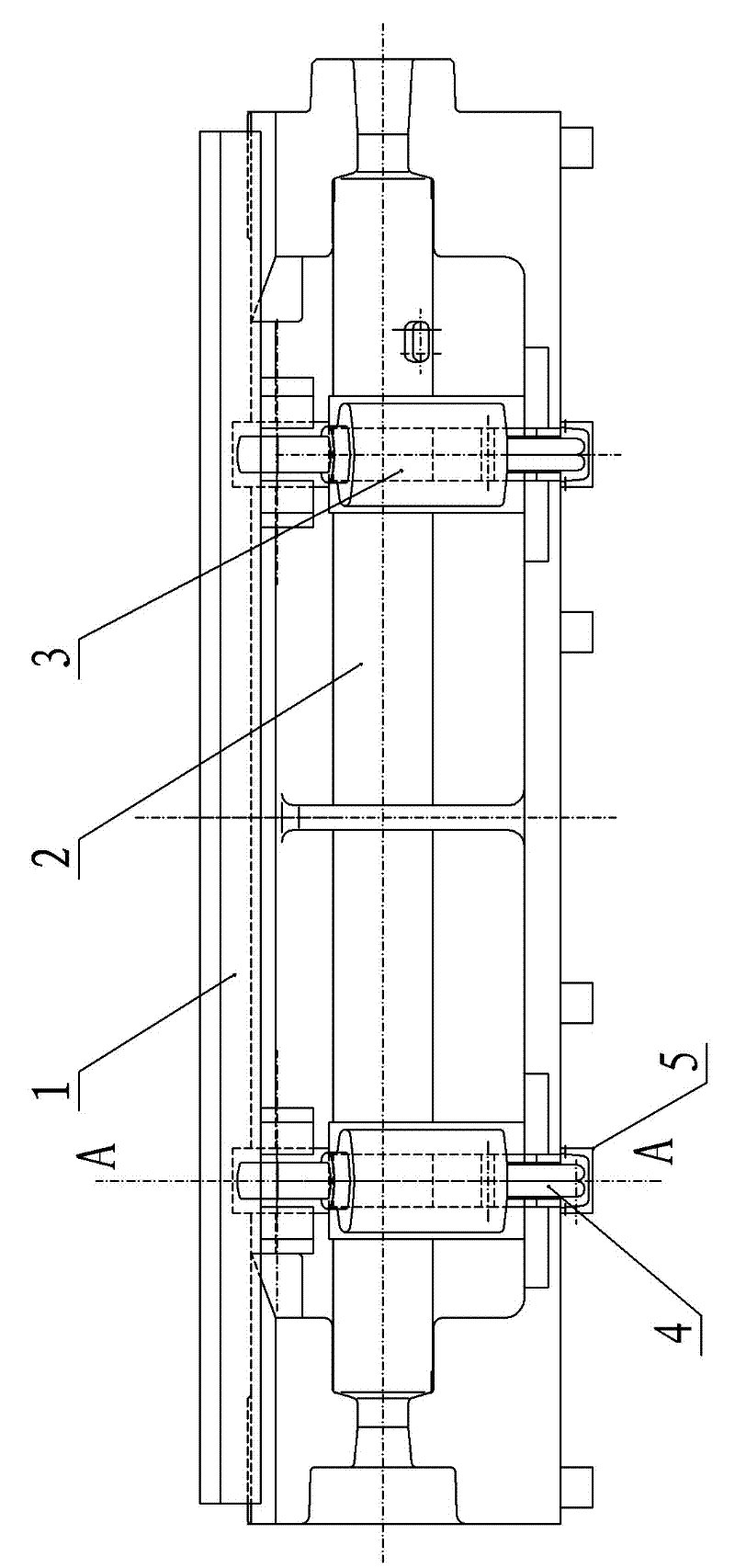

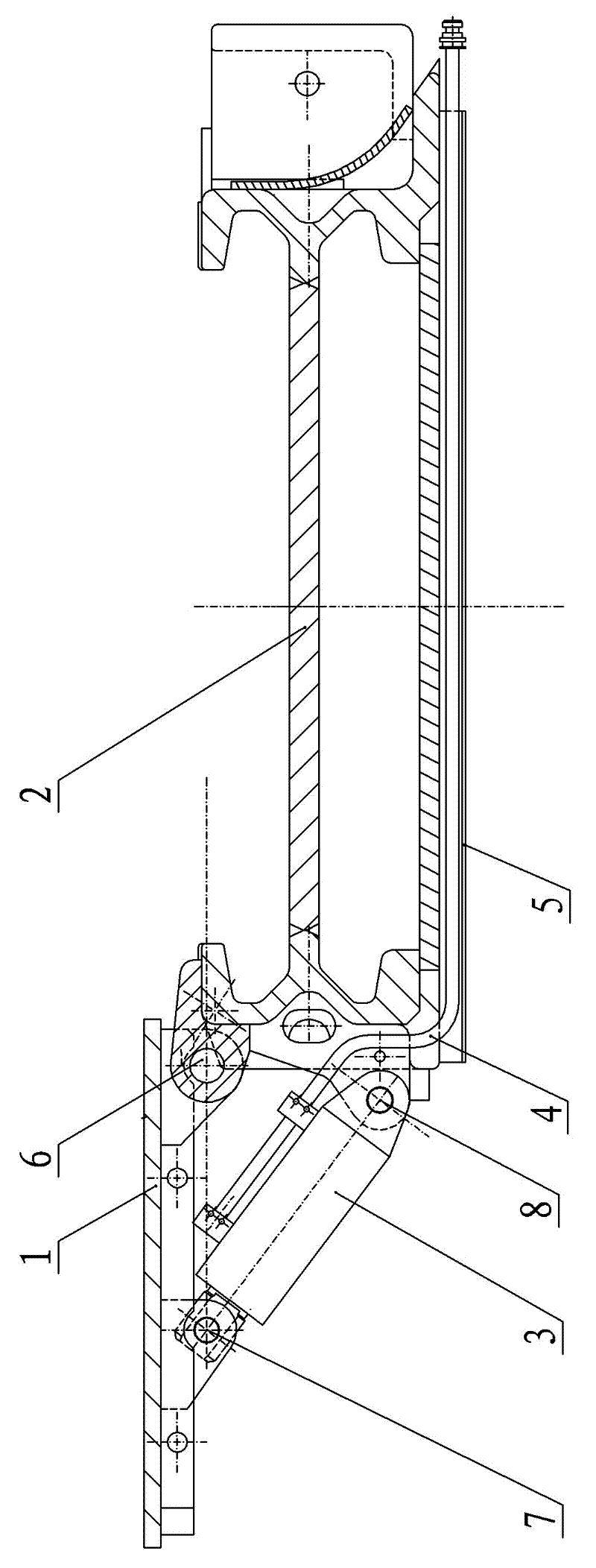

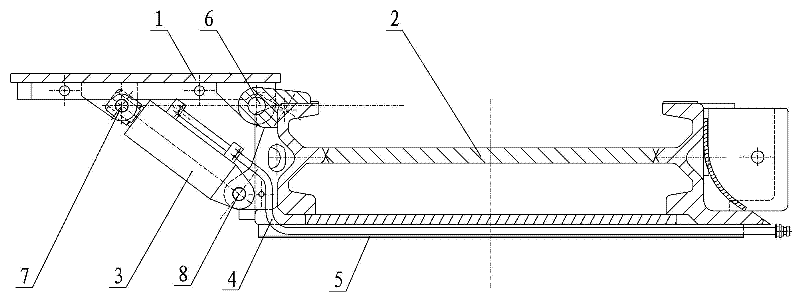

[0014] Example: see Figure 1-2 , a top-coal caving scraper conveyor with a movable coal collecting plate in the figure, the movable coal collecting plate is hinged on the upper edge of the baffle groove side of the middle groove of the scraper conveyor, and the movable coal collecting plate and the above-mentioned middle part A hydraulic cylinder is connected between the outer sides of the groove side of the groove baffle. The two ends of the hydraulic cylinder are respectively connected with the movable coal receiving plate and the middle groove through the hinge shaft. A hydraulic hose is connected to the hydraulic cylinder, and a bottom beam is provided at the bottom of the middle trough, and the bottom beam contains a trough-type bottom beam, and the trough-type bottom beam is buckled on the bottom surface of the middle trough, and the hydraulic soft The tubes are protected inside the channel sill. The center line of the hydraulic cylinder and the center line of the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com