Back frame and backlight system

A back frame and main splicing technology, which is applied in the field of back frame and backlight system, can solve the problems of high cost of back frame mold, excessive material consumption, high cost of back frame, etc., achieve material saving, simple mold structure, and solve problems that are not easy to fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

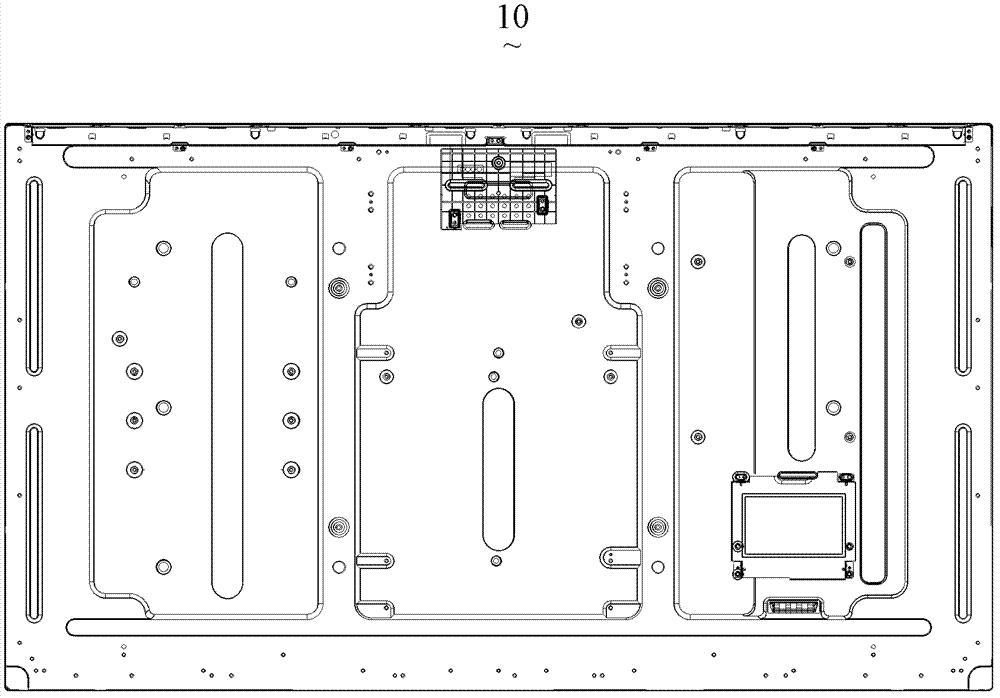

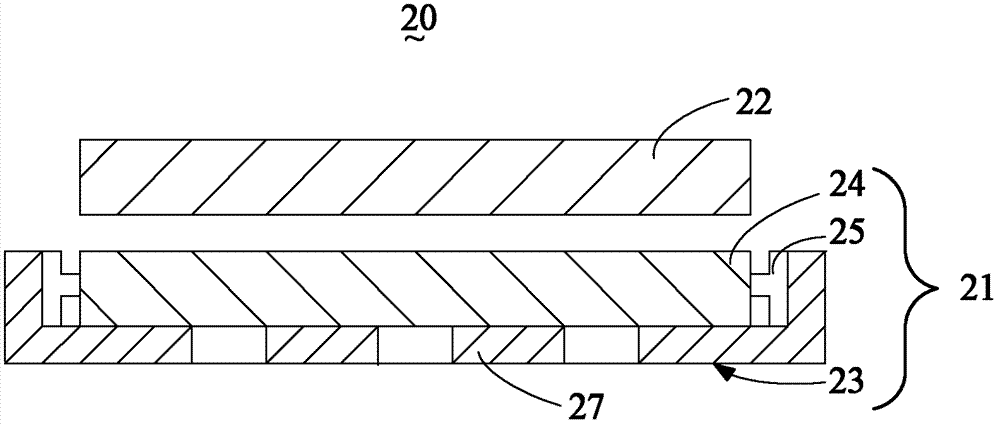

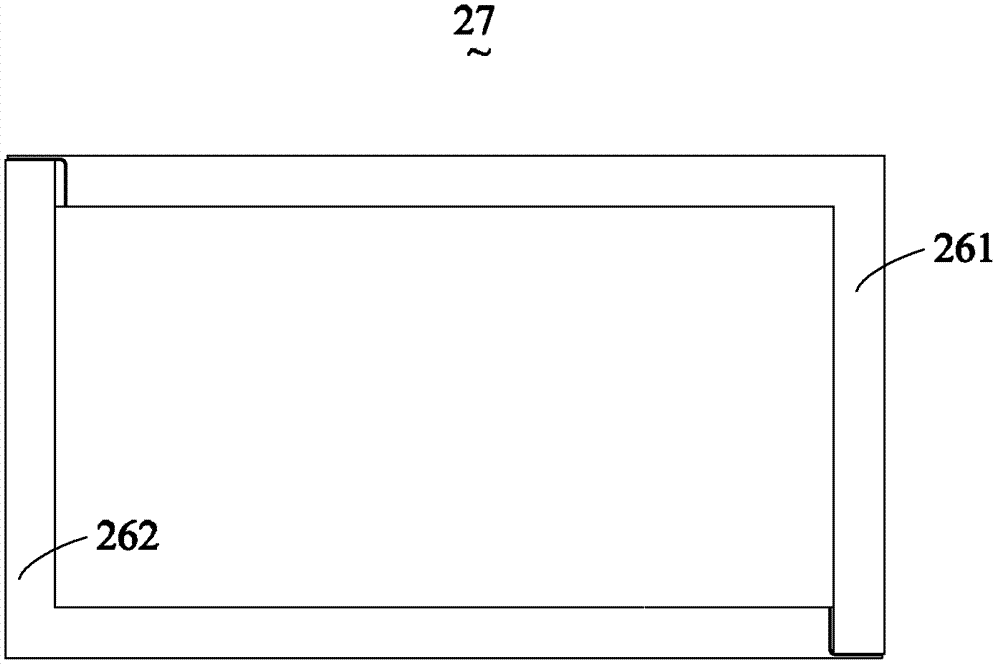

[0057] See Figure 2-3 , figure 2 is a schematic structural view of a flat panel display device according to a first embodiment of the present invention, image 3 is a schematic structural view of the back frame of the flat panel display device according to the second embodiment of the present invention. like figure 2 As shown, the flat panel display device 20 of this embodiment includes: a backlight system 21 and a display panel 22 , the backlight system 21 is disposed on the back of the display panel 22 and provides a light source for the display panel 22 .

[0058] In this embodiment, the backlight system 21 includes a light source 25 , a uniform light mechanism 24 and a back frame 23 . Wherein, the back frame 23 carries a light source 25 and a dodging mechanism 24 . When the backlight system 21 is a side-light type, the uniform light mechanism 24 is a light guide plate; when the backlight system 21 is a direct-light type, the light uniform mechanism 24 is a diffuser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com